Why Welder’s need to be Qualified?

The International codes (ASME Section IX, AWS D1.1, ASME B31.3) and standards (ISO 9606 series) require the welders to be qualified when they are welding on fabrications jobs that comply with construction codes (for example ASME Section VIII) or standards (e.g. EN 15085, EN 1090).

All the codes and standards have the main objective of verifying the welder’s ability to deposit sound weld.

The sound weld means weld that is free from welding defects such as crack, lack of fusion, lack of penetration, etc. Sound weld doe not mean free from imperfections such as porosity or slag inclusion.

These imperfections are allowed but within limits only as specified in their respective acceptance criteria in the applicable code or the standards.

The welder qualification test coupon or WQT as stated above needs to meet the weld soundness and that is verified either by performing a volumetric NDT test (such as radiographic testing or Ultrasonic testing) or by destructive testing such as bend test. Visual testing is mandatory but it is only for surface inspection.

Code and standards for Welders/ Welding Operator Qualification

Various international codes and standards are used for welder qualifications. The most commonly used Welder Qualification test codes are:

- AWS D1.1 Structural Welding – Steel : Certification : American Welding Society

- AWS D1.2, Structural Welding Code – Aluminum : Certification : American Welding Society

- ASME Section IX

- ISO 9606-1, ISO 9606-2

- CSA Standard W47.1

In this post, we will cover the most important variables that need to be considered when qualifying a welder and this is applicable to ASME Section IX, AWS D1.1 as well as ISO 9606 welder qualification.

How to Qualify a Welder: Steps for Welder Qualification Test

Before you make a welder qualification Test, you need to know the following welding conditions that will guide you to choose various essential variables for WQT to guide you on How to Qualify a Welder:

- Welding Process to be used

- Type of welding joint

- Material P Number and type (either plate or pipe)

- Electrode classification, its F-Number

- Weld thickness to be deposited

- Welding position

- Weld progression

All of the above parameters are actual parameters that the welder is going to use on the job. Based on these actual values, you can make a decision to choose:

- Material grade

- Welding position

- Material thickness & number of weld passes

- Weld progression.

Now, let us see these parameters in detail and their qualifying range in the ASME Section IX that will help you to understand the welder qualification process so you can perform the welder qualification Test task.

Step 1: Decide the welding process

The first and utmost task beforehand you start the welding qualification test is to decide the Type of Welding looking for a welder to qualify.

It is either Stick welding or TIG or GMAW, which could be anything or a combination of two welding processes.

- Shielded Metal Arc Welding or Stick Welding

- Gas Tungsten Arc Welding or TIG

- Gas Metal Arc Welding or MIG- MAG

- Flux Cored Arc Welding

- Submerged Arc Welding

Decide the welding type either Manual or semi-automatic or automatic.

Related Reading: What is Manual, Semi-Automatic, Mechanized, and Automatic Welding

Step 2: Look for the Welding variables

Now, once you decide on the welding process, the task becomes a bit easy as you can easily locate the essential variables for welder qualification test that are classified based on the welding process in ASME Section IX.

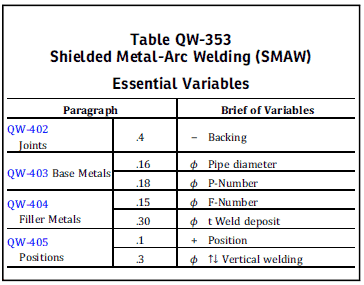

These variables are listed in ASME Section IX, clause QW-350. Here you will find tables from QW-352 to QW-357 for various processes.

Have a look at the essential variables listed for SMAW or stick welding in the below table (QW-353).

You must keep in mind that a new welder qualification test is required if the welder performs welding outside these qualified essential welding variables range.

Step 3: Gather the essential data

Now, you are on the right track to qualify a new welder. You have decided on the welding process, learn the essential variables for the selected process.

The next task is to gather the data based on your requirements (that could be from drawing or from the client-side).

Here, all the parameters that the welder going to use in actual welding need to be tabulated. For example Types of materials i.e. only carbon steel materials or stainless steel or copper alloy etc. So note down all of the following parameters:

1. Type of joint e.g. groove weld or fillet weld. For groove weld, as per QW402.4 for SMAW welding, removal of backing is essential variable.

Related Reading: What is a Groove Weld and its different types with Symbols

So if you qualified welder with backing, you can’t use him to weld on without backing welds. If required so, he need to be re-qualified using WQT without backing as this is an essential variable.

2. Base Material : Note down the base metal, its type, grade and most important is it’s P. Number (Table QW/QB-422 in ASME Section IX). Each material has a unique P. Number given by ASME Section IX. Click here to know what is P. Number.

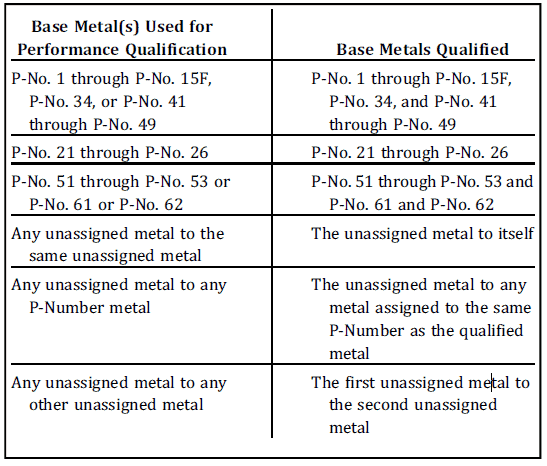

ASME Section IX gives umbrella for a range of material qualified with a certain material. For example, if a welder weld with P No. 1 material, he is qualified for P‐No. 1, 15F, 34, and P‐No. 41 to P‐No. 49 as permitted in QW 423.1, table shown below.

3. Range of material thickness (base Metal) qualified: Next, you need to make a summary of base metal thickness & pipe diameter if applicable, involved in the job.

Based on thickness and diameter you can choose the WQT thickness requirements for the plate, and thickness and diameter in case of a pipe WQT inline with QW-404.30.

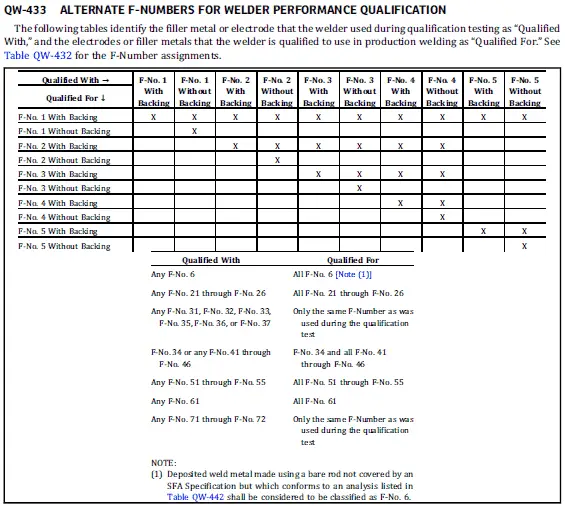

4. Filler Metal F- Number: each filler wire or electrode is given an F-Number in the ASME Section IX ( refer to Table QW-432 in ASME Section IX for all F-Number). The range of F-Number qualified is shown below.

Click here to learn What is ASME F-Number for filler metals is?

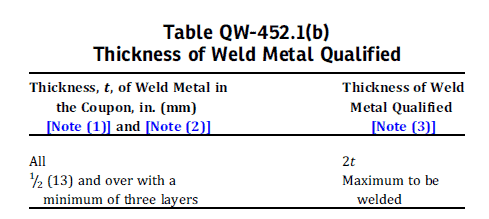

5. Range of Weld thickness (t) deposit qualified: As per QW-404.30, the thickness of weld in the WQT is the base for the thickness of weld deposit a welder can weld. The range of qualifications based on ‘t welded’ to ‘t qualified’ is given in the below table.

6. Selection of Welding position & weld progression: Welding position & weld progression are essential variables for welder qualification test.

The position used by the welder for WQT decides in which positions he or she can perform the welding in the actual job.

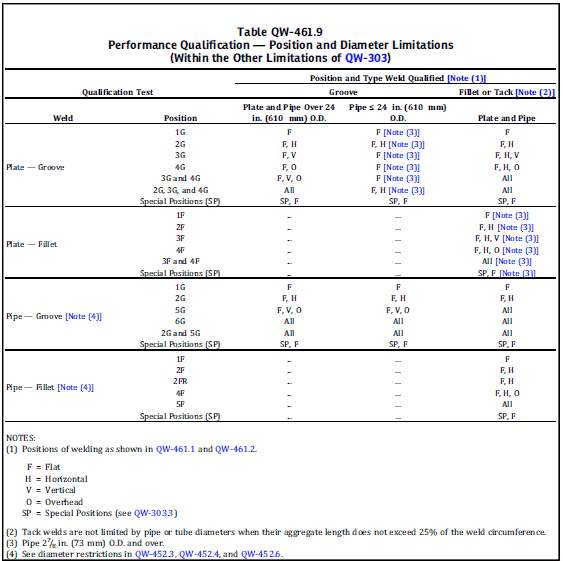

ASME Section IX, Table QW-461.9 provides the range of welding positions qualified based on performance welding test coupon position.

Summary for Welder Qualification Test preparation:

- Choose the Welding process applicable for Welder Qualification Test.

- Decide welding type: either Manual or semi-automatic for Welder Qualification Test.

- Select the WPS or Standard Welding Procedure Specifications (SWPS) to be followed.

- Select the weld joint type, decide either with backing or without backing.

- Decide the material type. either plate or pipe and its diameter for Welder Qualification Test.

- Find the P-Number of the the base metal according to the WPS or WQT.

- Find the F-Number of the the filler wire according to the WPS or WQT.

- Thickness (t) of the weld deposit from WQT thickness and joint type. Usually, equal to base metal thickness in full penetration groove welds.

- Decide the welding position & weld progression for Welder Qualification Test.

Preparation for the Performance Qualification Test Coupon or WQT

Welder Qualification Test Piece Size

The dimensions or sizes for welder qualification test coupons according to ASME Section IX for plate weld are a minimum of 150 millimeters (6 inches) in length X more than 100 millimeters (4 inches) width for welding suitability.

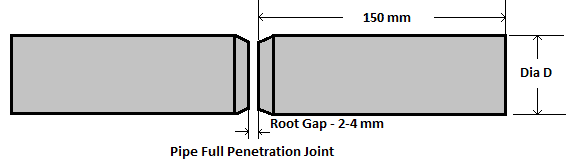

Similarly, the dimensions for welder qualification of pipe test coupons according to ASME Section IX shall have a minimum length of 150 millimeters (6 inches) on each side of the weld.

The total circumferential length of pipe shall be a minimum of 150 millimeters (6 inches), for small OD multiple coupons shall be welded but not more than 4 coupons as per Section IX. The dimensions of the Plate and pipe test coupon are shown below for reference.

Validity of Welder Certification?

What is the duration for the welder certificate is Valid? Does it expire? There are many such questions, most welders or quality persons came through.

To learn about the validity of a welder certificate Click the below link:

Related Reading: Welder certificate validity as per ASME Section IX, AWS D1.1, and ISO 9606

How often do Welders need to Recertify?

The American Welding Society (AWS) is a nonprofit organization that provides certification for welders. The AWS requires welders to recertify every three years.

There are two types of certification: welding performance qualification and welding operator qualification.

Welding performance qualifications prove that a welder can produce sound welds in accordance with the prescribed standards. A welding operator qualification demonstrates that a welder can operate the equipment safely and efficiently.

Recertification is important because it ensures that welders are up-to-date on the latest safety standards and procedures.

It also allows employers to verify that their employees are qualified to perform the work they were hired to do.

Similar Posts:

- How to be a Certified Welder?

- Welder qualification test WQT acceptance criteria as per AWS D1.1

- What is the Welder qualification test WQT acceptance criteria for ASME Section IX

- What is 6GR welding Test position? 6GR welding test tips and welder qualification

- What shall be the minimum & maximum length of tack welds & qualification requirements for Tack Welder?