Welder Qualification

Welding is a skill that is gained via hands-on experience throughout years of practice. Each welder or welding operator is used for fabrication by an organization that needs to meet the quality requirements calls for Welder/ Welding operator qualification via welding of test coupons.

There are various codes and standards such as ASME Section IX, AWS D1.1 or D1.2, or ISO 9606 series but all these codes, standards, and norms have the same objective: To ensure the soundness of the weld deposit by the welder.

Another common thing in all of these codes and standards is that the welders must remain engaged in the welding activities to keep his/her certification valid.

The main objective of weld soundness (Weld free from any defects ideally) is fulfilled by meeting the code/ standard requirements by:

- Welding a test coupon (either plate/ pipe)

- Testing (verifying the weld soundness) the test coupon by volumetric NDT (UT or RT) or Bend test/ fracture test.

- If acceptable, writing the welder certificate & the welder is considered to be qualified within the range permitted by the code or standard.

The question is now ”How Long this Welder Qualification is Valid?’ but first, let’s understand the difference between a welder and a welding operator.

Who is Welder or Welding Operator

Who is A Welder? A welder is a person (he or she) who performs a manual or semiautomatic welding operation while the welding operator is one who operates automatic welding equipment. So, the welder is one who performs the manipulation of the welding torch with his hand.

The wire feed or electrode feeding can be manual or semi-automatic. But, when the situation changes from the manual operation of the welding torch to automatic, he or she is regarded as Welding Operator.

Click here to know What is Manual, Semi-Automatic, Mechanized, and Automatic Welding

Validity of Welder/ Welding Operator Certification as per ASME Section IX

According to the ASME Section IX, clause QW 322.1, the welder/ Welding operator qualification never expires but conditions apply within the code limitation as:

”If a welder is engaged in the welding process for which he or she is qualified and there is no continuity gap of more than 6 months in his/her engagement in the qualified process. In case, he/she has not worked for the qualified process, his/her qualification will be void.

So, if a welder is performing welding activities within his qualification limit within every 6 month period and this activity is recorded via welder continuity, he or she remains qualified without any need for re-qualification.

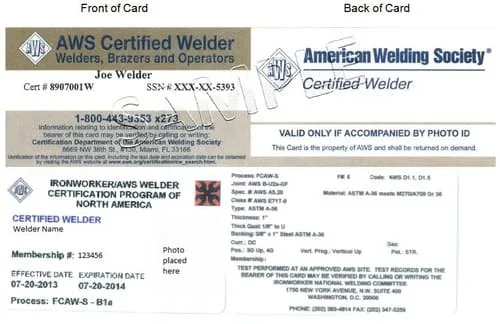

Validity of Welder/ Welding Operator Certification as per AWS D1.1

AWS D1.1, clause 6.2.3 Period of Effectiveness gives the details about welder certificate validity. As per this clause, the following conditions apply which are similar to ASME Section IX:

6.2.3.1 Welders and Welding Operators– As per AWS D1.1, the welder or operator qualification remains valid forever unless:

(1) If the welder is not performing the welding process for which he/she is qualified for more than 6 months duration, or

(2) There is a situation that is questioning the welder’s ability to perform a sound weld. For example- repeated welding quality failures in NDT tests- UT or RT.

So, as per AWS D1.1, the welder certification never expires as long as welder continuity is maintained by the organization & there are no questions about the welder’s ability to deposit sound welds. The same rules apply to the validity of tack welder certification and certification for tack welder remains valid as long as his/ her continuity is maintained.

Validity of Welder/ Welding Operator Certification as per ISO 9606-1

The welder certification according to ISO 9606-1, clause 9 Period of Validity states that the initial certification can be extended by the revalidation of the welder qualification. Revalidation means that the skills of the welder shall be periodically verified by one of the following methods:

- Retesting of the welder every 3 years.

- A welder needs to make welding of 2 test coupons every 2 years within the 6 months of the qualification validity period & test these coupons by RT or UT or DT. This shall be documented. This welding activity will revalidate the welder qualification for an extra 2 years period.

- The conformance of welder qualification according to clause 9.2 & meeting the below conditions keeps a welder certificate valid as long as they are meeting:

- The welder is working with the same company has an initial qualification,

- the company is having a quality system as per ISO 3834-2 or ISO 3834-3 standard;

- The company has documented the welder qualification process where the welder has produced sound-quality welds.

So, as per ISO 9606-1, the welder needs to be tested on regular basis either a retest every 3 years or recording evidence (RT or UT record) of sound weld deposit every 2 years or continuity within every 6 month period for the company certified with ISO 3834 certification.

Click here to know about ISO 3834 certification and its requirements

Welder qualifications is a testing system to prove and validate that a welder can produce sound welds by periodically testing & verifying the same. A good welder should be a person as:

a) Responsible for the quality & workmanship of weldments.

b) Welder meets qualification requirements as per the applicable code & standards.

c) Welder is familiar with the WPS and job requirements based on drawing and weld plan.

d) Welder can use all welding-related tools that assist him to ensure weld quality.

e) Welder understands the inspection hold-points.