What is the Welder qualification test or WQT meaning in Welding?

Straightforward answer: WQT refers to Welders Qualification Test. You will hear this frequently among welders & welding Inspectors.

It’s a non-standard phrase. Welding qualification standards & code cite WQT to Welder Performance Qualifications (WPQ) which stand for assessment for welder performance qualification or also called WPQ.

WQT or WPQ test is run for a welder to prove his/her ability to deposit sound welds meeting given codes or standards requirements. Welder performance qualifications (WPQ) meet the requirements for the WPS qualification.

Welder qualification test acceptance criteria as per ASME Section IX

Visual test Acceptance as per ASME Section IX

As per ASME Section IX, Clause QW-302.4 Visual Examination acceptance for welder test (WPQ) or WQT coupon is specified in clause QW-194.

After the welding of the test coupon is finished, the final WQT shall be visually inspected except for the area marked as discarded.

This visual inspection shall be before the cutting of bend test if bend testing is required. For visual inspection of pipe WQT, the entire circumference, inside and outside of the pipe shall be examined.

The acceptance for visual inspection as per ASME Section IX, clause WQ-194 is:

”Performance test (WQT) coupons shall be free from cracks and

show full joint penetration with complete fusion of the weld

metal and base metal.”

The codes haven’t specified the requirements of other defects such as undercut, surface pores, excessive root penetration, underfill, etc.

Now, as the WQT is a test to evaluate and verify the welder or welding operator’s ability to produce sound welds, the defects specified above must not be present in the weld.

Minor undercut which is small in length and depth can be accepted but based on the judgment of the examining body.

RT/ UT (Volumetric NDT) Acceptance as per ASME Section IX

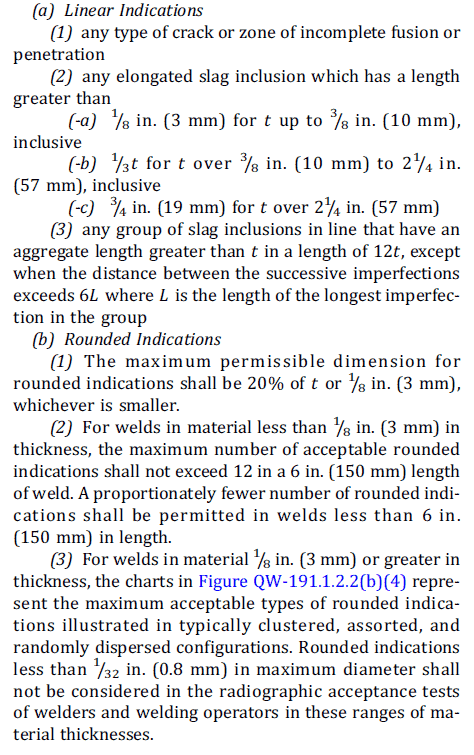

The radiographic acceptance for the welder or welding operator performance test or WQT is given in the ASME Section IX, Clause QW-191.1 Radiographic Examination and shall meet the requirements of Section V, Article 2. The Radiographic film indication acceptance shall be based on:

- Linear Indication: Indication having a length more than 3 times the width of the indication.

- Rounded Indication: Indication having a length less than 3 times the width of the indication.

Bend Test Acceptance as per ASME Section IX

As allowed in ASME Section IX, QW-304.1 Examination, the final welded WQT shall be examined by Visual Testing and Mechanical Testing (Bend test).

The Bend testing can be substituted by Volumetric NDT either RT or UT within the limits specified in QW 304.

Related Reading: Bend Test for Welder Qualification

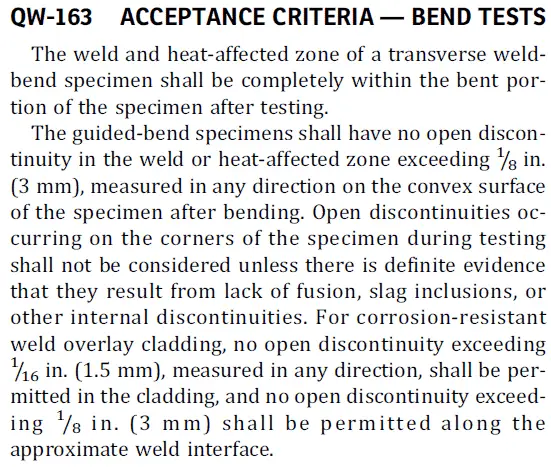

When testing the welder by bend test, the bend test shall meet the acceptance criteria defined in clause QW 163 of ASME Section IX. In the bend test, the HAZ and weld shall be within the bend portion for the transverse bend test. For the acceptance of the bend test:

- The bend test specimen after bending shall not show any open discontinuity in the weld or HAZ more than 1/8 inch or 3 mm as given in the below picture.

Ultrasonic Testing Acceptance as per ASME Section IX

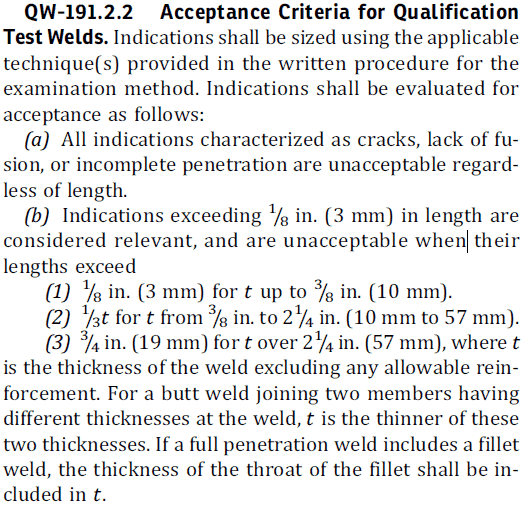

UT test acceptance criteria for welder performance qualification or WQT are given in clause QW-191.2.2 Acceptance Criteria for Qualification Test Welds.

In UT indications such as crack, lack of fusion and incomplete penetration are not acceptable at all. Other indications such as porosity or underfill etc. are acceptable when their length is more than 3 mm or as given below.