What is a Welding Crack?

A welding crack is a material separation that does not encompass the entire cross-section of a welding joint, component, or material, not yet causing it to fall apart. Cracks are in most cases starting points of a fracture.

Welding Cracks are fracture-type linear imperfections having a sharp tip with a higher length and very small width. Welding cracks can appear in weld deposits, heat-affected zone (HAZ), and base material. They occur once the localized stresses exceed the ultimate tensile strength of the base metal.

Initial Cracking usually starts at stress concentrations due to other defects or sharp notches (notches work as stress concentration) in the nearby area. These stresses can be residual stresses caused by the welding or stresses got applied due to service or another external loading.

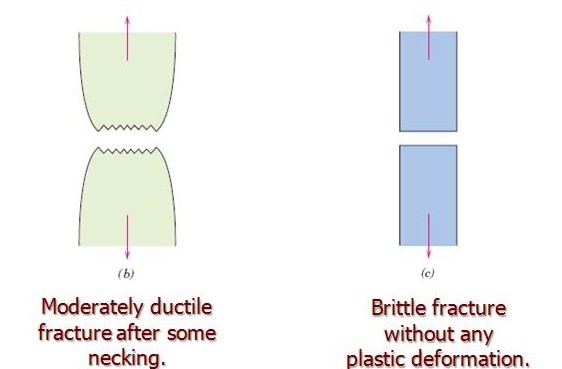

In welding, residual stresses are caused by weld solidification and thermal expansion properties of the metal. In welding cracks, there is little plastic deformation as most of the cracks either occur due to high hardness or Stress.

Classification of Welding Cracks:

- Metallurgical caused cracking: Hot crack, Shrinkage Crack

- Technologically caused Cracking: Crack due to wrong heat treatment

- Load caused cracking: Stress corrosion cracking, Hydrogen cracking

Types of Welding Cracks Based on Size

Cracks based on their size are classified into:

- Macro cracks: Visible with the naked eye or with a magnifying glass

- Microcracks: Visible under a metallographic microscope

Further classification can be based on how the cracks propagate, as:

- Inter-crystalline crack: Cracks propagating along the grains

- Trans-crystalline crack: Cracks propagating through complete microstructure areas.

What are the Types of Welding Cracks?

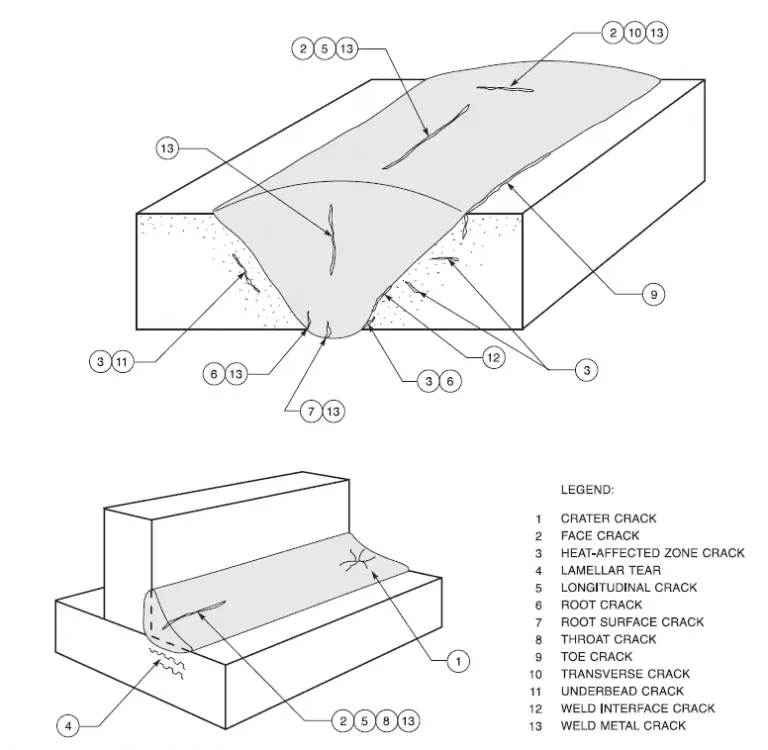

Various types of cracking are found in welding applications. The cracks types, their appearance, and locations significantly affect the service life of the components especially when they are under cyclic loading applications.

As we know cyclic loading can easily create failure of the part if any notches or cracks are present. Each type of cracking found in welding is caused due to particular reasons either single or in combinations.

For example, delayed cracking is caused due to presence of hydrogen, stresses, and hard microstructure. So, it’s the conditions that affect the appearance of the cracks in the weldment.

Cold Cracks vs. Hot Cracks

In general, cracks are classified as:

- Cold cracks e.g. delayed cracking, fatigue cracks

- Hot Crack e.g. Solidification cracking

Hot cracking appears at the solidification stage of the welding. The main reason for hot cracks is the lack of ductility at elevated temperatures. Hot cracking is found mostly at the center of the weld as, during solidification, this is the area that solidifies at the last.

These cracks propagate between weld deposit grains or the interface of the welding. On the other hand, cold cracks do not appear at the solidification stage but rather they are found after the solidification stage is completed after the welding or simply once the welding is completed.

Cold Crack is also known as hydrogen cracking or delayed cracking as these cracks are generated due to the presence of hydrogen and can appear after several hours of the welding or even after days after welding is done. Cold cracking is found in HAZ, weld metal as well as in base metal. Delayed cracking propagates through the grains as well as between the grains.

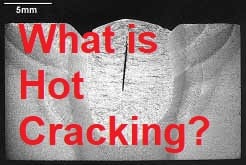

What is Hot Crack and its Types?

Hot cracks appear in the weldment due to various associated phenomena. Hot crack is the type of crack appearance that results in the presence of molten or brittle phases on the grain boundaries at high temperatures.

Hot Cracks have the following types:

- Solidification Cracking

- Liquation Cracking

- Crack due to a reduction of deformability

- Centerline cracking

Hot cracks formed in the area of welding are called solidification cracks. They are generated during the crystallization of the base material from the liquid phase and frequently reach up to the surface of the weld metal forming either center cracking or end crater cracking.

The cracks can be either find by visual testing or by performing liquid penetration testing or magnetic particle testing.

What is Longitudinal vs. Transverse Cracks?

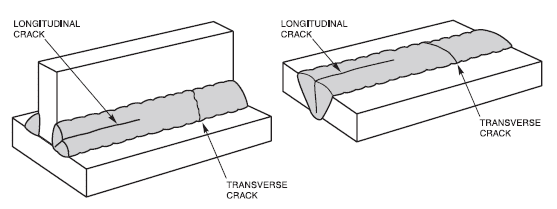

A longitudinal crack is parallel to the weld axis. Any crack appearing at Weld, HAZ or fusion line will be called a longitudinal crack such as a centerline crack in weld metal or a toe crack in the base material or HAZ. Longitudinal cracks are shown in the below picture.

When welding small length tack weld or small welds between heavy to thin members, longitudinal cracks appears due to high cooling rate and high restraint. In HAZ, longitudinal cracks are caused due to dissolved hydrogen in the weld metal during solidification.

Transverse cracks found in submerged arc welds are caused due to high welding travel speed and could be associated with porosity. Types of weld cracks that appear perpendicular to the weld axis are called Transverse Cracks. Transverse cracks are small in size compared to the longitudinal cracks and mostly within the width of the total weld bead as shown in the below picture.

Transverse cracks can also propagate into the HAZ and base metal. In high-strength materials, transverse cracks can easily develop if preheat and hydrogen level is not controlled and they can appear only in the heat-affected zone.

Most of such cracks are caused by the longitudinal shrinkage stresses working on low ductile weld metal which is the case in most of the high strength materials. Hydrogen cracking or cold cracking can also show a similar pattern of transverse cracking.

What is Crater Crack?

When performing fusion welding processes such as stick welding or MIG or TIG and if the end of the weld is not properly terminated, it can result in starlike network crack formation as shown in the below picture.

The crack appearing at the end crater in welding is called a Crater Crack or star called as called sometimes. Crater cracks are types of hot cracks as cracking occurs during the solidification stage.

Materials that exhibit high thermal coefficients such as Austenitic stainless steel or aluminum are more prone to crater cracks as heat will be dissipated very fast and there will be high stresses in the underfilled crater.

The prevention of crater cracks or Crater cracks can be prevented by:

- Filling the adequate end crater.

- Using the back step technique at the weld end.

- Ensure a slightly convex shape at the weld end by welding.

- Using short arc.

What is Toe Crack?

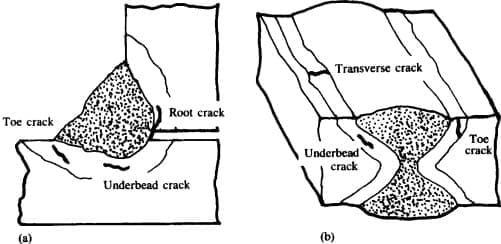

Toe crack is a type of cold crack as shown in the below picture that appears at the weld toes. Toe crack’s starting point is the weld toes in fillet weld or groove weld. These are locations of maximum shrinkage stress concentration in a weld joint. These types of cracks start from the base metal area approximately.

Toe crack open to the surface can be easily detected by Visual Testing & surface NDT methods (e.g. Penetrant Testing & Magnetic particle Testing).

The cracks occur due to the effect of the welding thermal stresses working on the HAZ. Few Tor cracks initiate due to lack of base metal ductility where the weld zone is not able to withstand these stresses & resulting in the separation as crack.

What is Underbead & Heat-Affected-Zone Crack?

Underbead or heat-affected-zone (HAZ) crack can be used with the same meaning. Both of them are types of delayed cracking occurring in weld HAZ. Typical underbead cracks are illustrated in the below Figure. Underbead cracks can occur when three elements are present simultaneously:

(1) Hydrogen

(2) A microstructure of relatively low ductility

(3) High residual stress

Underbred and HAZ cracks can appear in longitudinal and transverse directions. These types of cracks are noticed in the HAZ and are not always detectable by visual (Visual Testing) examination.

Mainly such a type of cracking occurs in T Joints (Fillet Welds) although you may notice them in groove welds also.

What is Root Crack?

Root cracks appear in the root of the weld in the longitudinal direction. They can appear on the root surface or within the root. Root cracks can be caused by delayed cracking as well as hot cracking type. cracks at the weld root or in the root surface. Root cracks are shown in the above Figure.