Learn about the Heat Affected Zone (HAZ) in welding and its significance. Understand how welding heat can affect the surrounding material, leading to changes in mechanical properties. Discover the factors influencing HAZ formation and ways to mitigate its negative effects.

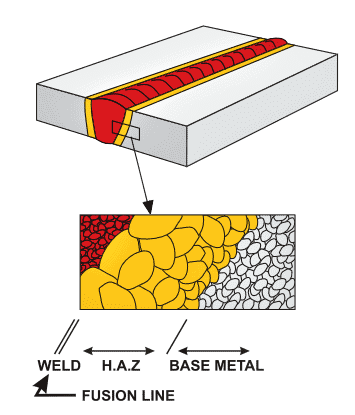

Heat Affected Zone or HAZ in Welding is the zone adjacent to the weld metal that is not melted but altered by the welding thermal cycle. The alteration refers to the changes in the mechanical & microstructural properties.

What is HAZ or Heat Affected Zone in Welding?

HAZ stands for Heat Affected Zone in Welding Joint. Heat affected zone in welding is the area that is affected by the welding heat. This is a general understanding to limit the welding area only within the weld metal fused in the welding joint. Although, this is not true.

The accurate area for a welding joint includes the base metal that has been altered (changes in microstructural & mechanical properties) by the welding heat input. This area is called Heat Affected Zone in welding or HAZ in Welding. Depending on the amount of welding heat input, the size of the heat affected zone varies.

What are the HAZ Regions or Areas in Welding?

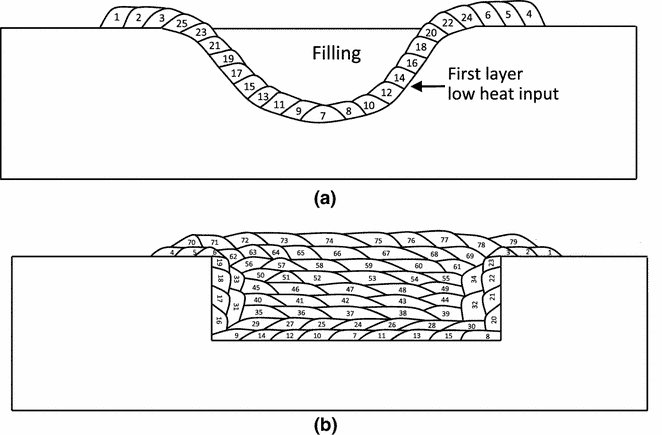

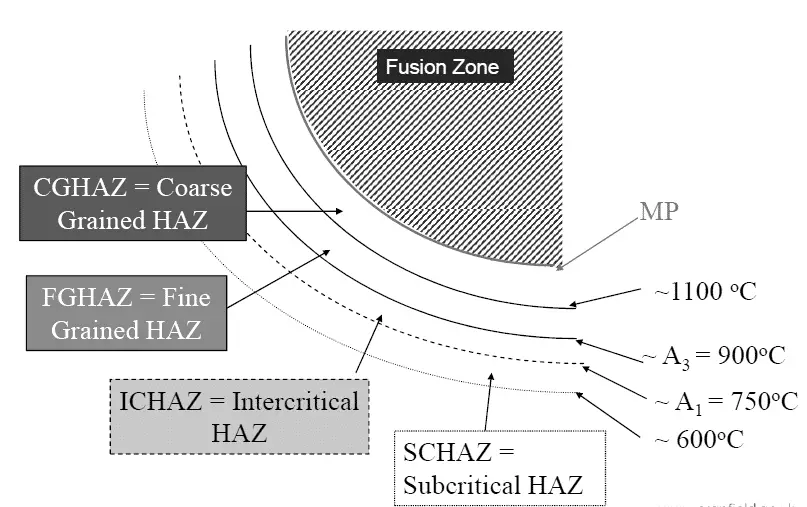

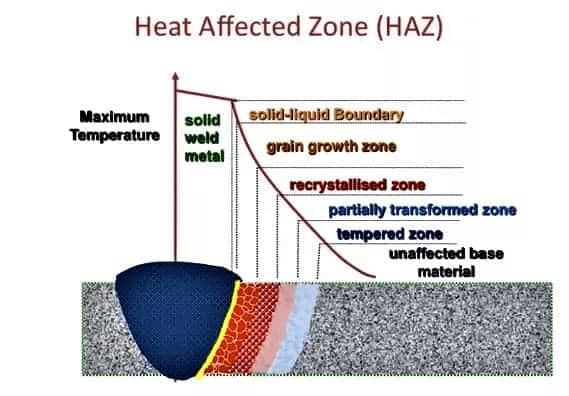

Weld HAZ is the region within the parent material that surrounds the weld where the microstructure changes due to the thermal cycle during welding. So, a HAZ in Welding is composed of the following main regions in the below Figure :

1. Melted region (weld metal)

2. Bonding region (fusion line)

3. Base metal heat affected zone (HAZ)

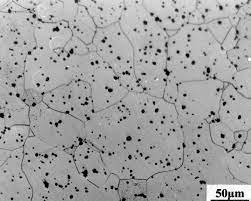

Based on transformations that take place in HAZ, the Heat Affected Zone (HAZ) grain structure types are:

- CGHAZ means- Coarse Grain HAZ

- FGHAZ means– Fine Grain HAZ

- ICHAZ means– Inter-critical HAZ

- SCHAZ means– Sub-critical HAZ

What are the Temperatures in Heat Affected Zone in welding or HAZ?

The temperature range at the fusion line is approximately 1450ºC-1500ºC ( 2642°F- 2732°F) and consists of weld metal and parent material mixture. The temperatures found in the coarse-grained HAZ in welding are approximately between the melting point and 1100ºC (2012°F).

Fine-grained HAZ in welding temperatures range from approximately 900ºC to 1100ºC (1652- 2012°F). The inter-critical HAZ in welding temperature ranges between 750ºC-900ºC (1382- 1652°F) with only carbon-rich zones transforming to austenite during heating.

Size of HAZ in welding increases with increase in total welding heat Input. The factors that affects the heat input are:

- High welding current/ Amperage

- High welding voltage

- Reduced travel speed

- Weld weaving, etc.

So what is HAZ or Heat Affected Zone in Welding Definition?

During the welding operation, the region of base material adjacent to the welding zone does not fuse but is affected by the welding heat input. The heat input effect brings changes as microstructural changes and changes in mechanical properties to this base metal region.

This specific area affected by the thermal energy of the welding is called Heat Affected Zone or HAZ in welding. The welding thermal cycle produced by the welding works similar to heat treatment and changes the HAZ in welding properties (microstructural & mechanical properties such as microstructure, hardness, yield strength & toughness).

Heat Affected Zone in Welding or HAZ Width (Distance)?

How far is the heat affected zone in welding?

Heat affected zone in welding dimensions such as width, measured on a cross-sectional microstructure of the weld depend on the welding heat input and the thermal conductivity of the base metal. A welding process that gives high heat input (e.g. SAW) will produce wider HAZ in welding compared to one that gives low heat input such as Stick welding.

The 2nd factor that is the thermal conductivity of the material influences the heat dissipation during welding & also affects the HAZ width. Materials with low thermal conductivity will give wide & large HAZ (for example stainless steel compared to carbon steel) and materials with high thermal conductivity (e.g. copper) will have narrow HAZ in welding.

The width of HAZ in Stick welding or SMAW and TIG welding is usually around 1 to 2 mm.

HAZ- Heat Affected Zone Distance Between Welds

The distance between the two heat affected zones should be a minimum of 50 millimeters or 2 inches. The minimum heat affected zone in welding or minimum HAZ in welding is not referenced in any standard or code. But HAZ in welding should be minimum so that there is least alteration of the base metal properties.

Heat Affected Zone (HAZ) Cracking

Different types of cracks appear in the Heat Affected Zone or HAZ in welding. The nature of these cracks is stress-caused. An example of stress-caused crack is Hydrogen Cracking (also called cold cracking or delayed cracking).

Other phenomena associated with stress also cause HAZ cracks which are mainly Sulphide stress corrosion cracking (SSCC), lamellar tearing, and stress corrosion cracking- for example.

Properties and Transformation During Welding in HAZ?

The HAZ properties are influenced by the steel’s chemical composition, its thickness, and the time-temperature cycle during the welding process. The maximum temperature reached during welding needs to be considered when assessing the weldability of steel. The peak temperature has the following influence:

• The dissolution of microalloying precipitates in the grain coarsened HAZ in welding

• The austenite grain growth

• The cooling rate from the peak temperature

The iron-carbon phase diagram shows that a phase transformation starts when the temperature reaches 723°C (1333.4°F).

At that temperature, BCC transforms into FCC. Since weld cooling rates from temperatures above 723°C (1333.4°F) may be rapid, hardening of the weld area is common. The heat affected zone (HAZ) is a very important area because weld faults may occur in this zone.

Why is the Heat Affected Zone in Welding Important?

Different types of microstructural transformation take place in the heat affected zone in welding based on the highest temperature reached in each of these areas during welding. Depending on the temperature, different HAZ regions occur with distinct properties.

Wider the HAZ, the higher the properties variations. These changes that occurred in the HAZ in welding are not the same as the base metal and are mostly having inferior properties.

It is a general aim to keep the HAZ width low to avoid these changes although this can not be eliminated. The weakest area in HAZ is close to the fusion line. This grain growth area is made up of coarse grains where the temperature is just below the melting temperature of the base metal. Due to large coarse grains, it is the weakest part in the heat affected zone or HAZ in welding.

Click here to calculate the Transformation temperature in Steel using its alloying elements.

How to Control & Minimize the HAZ Width?

For low alloy steel and micro-alloyed alloys, it is very essential to limit the HAZ width and thus control to HAZ grain growth. The width of HAZ in welding can be reduced and controlled by:

- Using low heat input,

- Welding with stringer beads, and

- Strict compliance to the interpass temperature limit.

- Use of weaving shall be restricted as weaving produces high heat input due to reduced travel speed.

Why Weld Usually Fails in HAZ?

The heat affected zone (HAZ) undergoes myriad microstructural changes at very short distances. Welding HAZ consists of coarse grains, medium-size grains, and fine grains as explained earlier. This inhomogeneity in microstructure degrades the welding joints’ properties and results in HAZ lower mechanical properties, especially toughness and high hardness.

An increase in HAZ hardness is one of the main issues that require stringent controls during the welding of low alloy steels and high carbon steels. As the maximum hardness permitted for these materials are 250 HV according to NACE MR0175.

Another main concern in the HAZ is the reduction of Charpy V Notch toughness. The HAZ toughness reduces due to the formation of wider coarse grains due to high temperatures below the melting point in the HAZ. Note that not all HAZ toughness gets reduced, the area of finer grains exhibits high HAZ toughness. The main culprit is the coarse grain HAZ region.

Factors affecting heat affected zone in Welding or HAZ

The main factors affecting heat affected zone in welding or HAZ in welding are:

- Welding heat input

- Welding current, voltage

- Welding travel speed

- Welding technique- Weaving or stringer beads

- Welding positions

- Welding preheat

- Control of interpass temperature

- Base metal properties- thermal conductivity