What is Consumable insert in Welding & its definition?

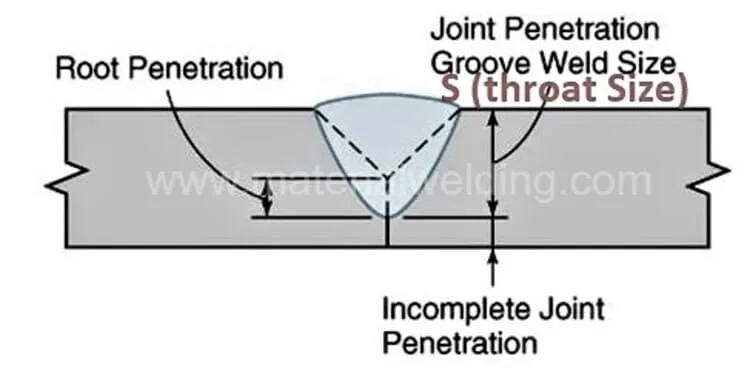

Consumable inserts are metal strips in special sizes and dimensions that are used for root pass welding with one side access.

Consumables inserts are beneficial for high-quality welds that are required with minimum repairs, or rejects, and where welding conditions may be less than optimum, such as a limited area for welding.

It also ensures that the weld can be free from cracks and lack of root penetration & fusion issues.

Consumables inserts are used mainly for piping, pressure vessels, and other weld structures with one side welding access. They are available as strips for a flat plate.

Consumables inserts are made of similar metallurgy as the welding wire of base metal. Dissimilar metallurgy inserts are not suitable for welding.

The reason is that they will melt and produce unwanted weld chemistry due to weld dilution that will affect the weld joint mechanical and chemical properties.

For example- corrosion resistance, tensile strength, or weld toughness.

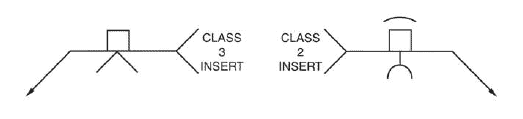

Consumable insert weld symbol

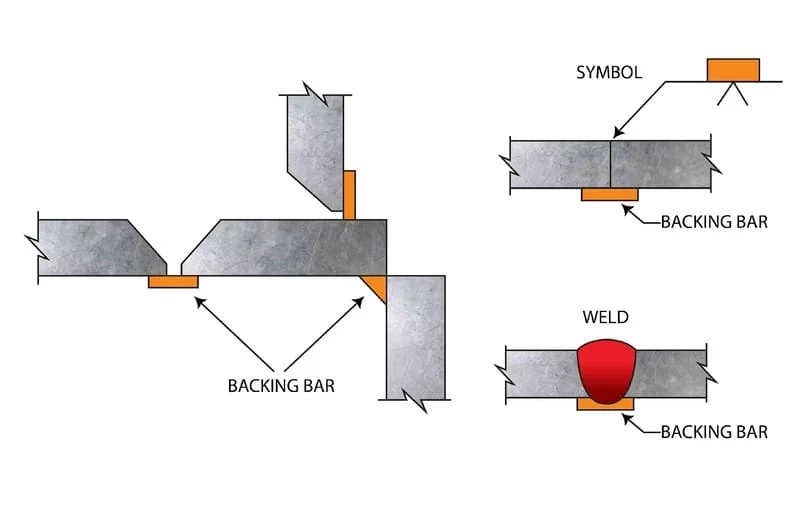

The welding symbol for consumable inserts is specified by placing the consumable insert symbol on the side of the reference line and opposite to the groove weld symbol as shown in the below figure.

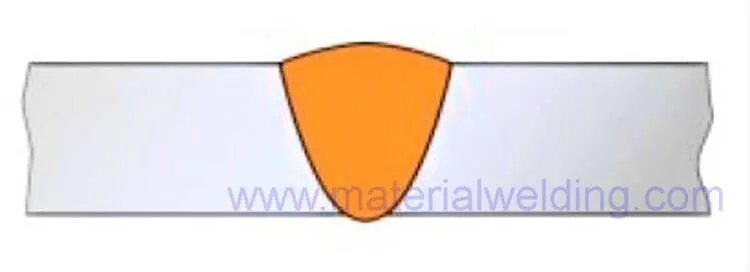

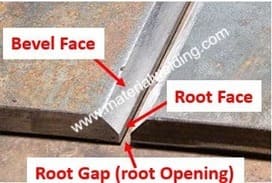

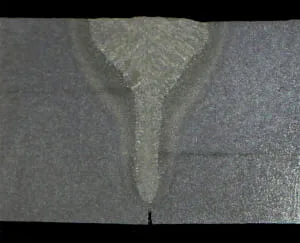

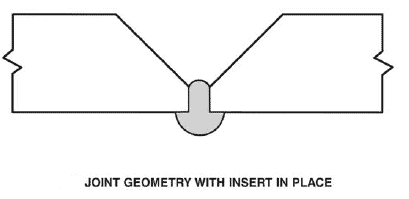

The weld geometry with insert application is shown below with a groove weld example.

The insert is placed in the groove weld, either pipe or plate joint thus allowing an open root similar to with backing appearance.

The AWS consumable insert class may be placed on the tail of the welding symbol. The classes for welding consumables are classified into 5 classes.

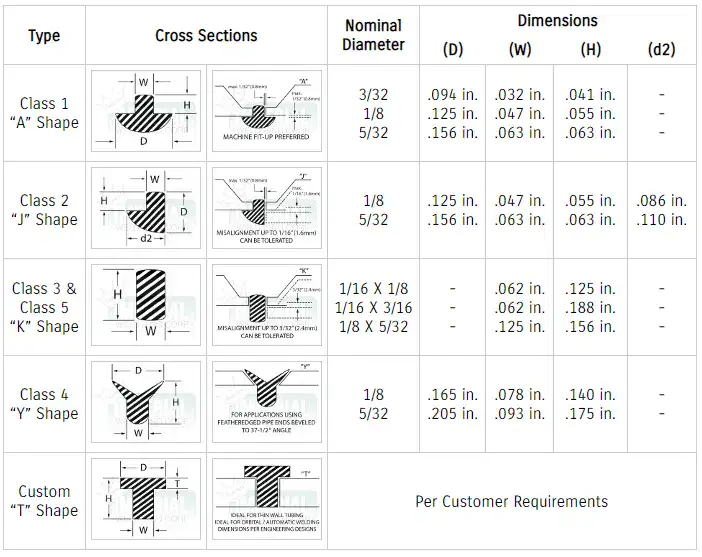

Welding consumables inserts are classified as per ASME Section IIC, SFA 5.30 into 5 classes:

- Class 1: Inverted T-Shaped Cross-Section

- Class 2: J Shape Cross-Section

- Class 3: Solid Ring Inserts

- Class 4: Y Shape Cross-Section

- Class 5: Rectangular-Shaped Cross Section (Contoured Edges)

The diameter and dimensions of class 1, class 2, class 3, class 4, and class 5 consumables inserts are given in the below table.

consumable insert for gtaw

Consumable inserts or fusible inserts for TIG welding are classified as per AWS A5.30 in 5 classes and 4 shapes A, J, K, and Y.

The same consumables inserts are used with other welding processes such as stick welding or MIG-MAG welding.

Consumable inserts or backing rings are used to control penetration and the inside contour with TIG welding.

consumable insert vs backing ring

Both consumables inserts and backing ring provide a surface for weld bead before depositing.

The backing rings usually are not part of the welds and they can be temporary (removable backing) or permanent type while the welding consumables inserts are fused with the weld and they become part of the weld itself.

The backing ring can be either the same metallurgy or copper backing or ceramic backing while the consumables inserts are always the same metallurgy as the welding filler and base metal.

Backing rings are mostly made of metals and provide backing to the weld beads to be deposited. Backing rings are Backing in the form of a ring, generally used in the welding of pipe.

Use of consumable insert

Consumable inserts are used for various purposes. They help for ease in weld joint fit-up. By using inserts, a uniform weld root is achieved which results in high-quality weld joints without any rejections in radiography or visual inspection.

This becomes very important to use inserts in critical welds used in nuclear projects or military projects that use costly materials and each repair can increase their overall cost. Thus with inserts, it helps in quite a lot of saving.

Welding inserts help the welders to weld with a uniform root gap and even weld joint profiles. The weld roots produce very good fusion with the weld ID, especially when welding small or large diameters pipe where only side access is available.

Consumable inserts give higher welding speed compare to weld without inserts as a welder can weld faster without any worry of root such as back or burn through. This also helps to save the welding filler wire.

How to choose consumable insert for welding?

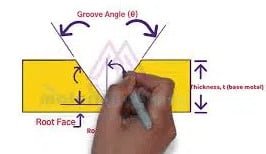

The selection of the right shape of a consumable insert is to be decided by the design engineer based on the requirements.

The design engineer should consult the authorized welding engineer for weld accessibility and metallurgical suitability of welding inserts.

The service conditions also define the usage of consumable inserts for example, class 1 shape inserts are used for high-critical welds that are used in nuclear plant piping and high-pressure piping applications. Class 2 inserts can be used for non-critical jobs where alignment is not an issue.

Class 3 inserts have the same chemistry as the welding wires and can be a good replacement for root run welding without filler.

Class 4 inserts are used for V-groove weld joints. Class 5 inserts are similar to class 3 but they are available as a solid ring that can be customized to different needs.