What is a Full Penetration Weld?

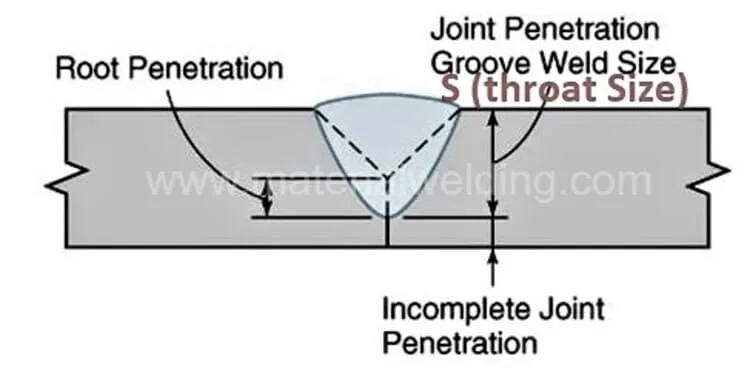

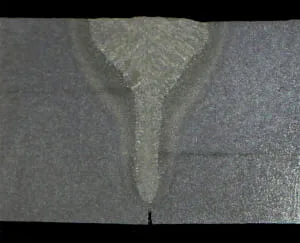

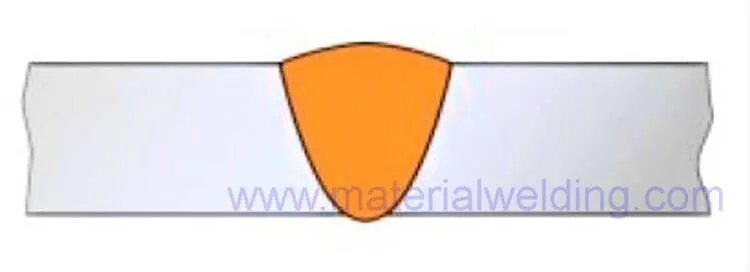

A Full Penetration Weld (FP Weld) or also called Complete Joint Penetration (CJP) weld is a type of weld in which the weld metal completely fills the entire thickness of the base metal at the joint & extend through the base metal thickness.

A full penetration weld is a non-standard term used for complete joint penetration weld.

This results in a weld that is penetrating through the weld root to flush to the base metal on both sides of the weld joint.

The joint efficiency of full penetration welds when tested by 100%RT is considered equal to the base metal strength as they can transfer the full load via the welded members. This is subjected to that a matching strength welding filler wire is used for welding.

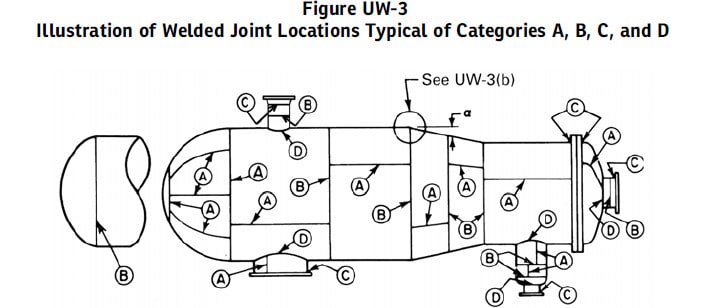

Full penetration welds are typically used in applications that require high strength and integrity of the joint, such as in the construction of pressure vessels, boilers, and other types of high-pressure equipment.

They are also commonly used in the fabrication of structural steel, piping systems, and other types of heavy equipment.

It’s important to note that not all types of joints can be made with full penetration weld, for example, fillet welds are not full penetration welds by definition, as their design is to provide a certain type of load transfer, mainly shear loading.

Full weld meaning

A full weld is a non-standard term used to describe a weld that has been completed to the full depth of the joint.

It is also called a full penetration weld. This means that the weld metal has completely filled the entire thickness of the base metal at the joint and has created a bond that is flush with the surface of the base metal on both sides of the joint.

Full welds are considered to be the strongest type of weld as they provide maximum strength and integrity to the joint.

They are typically used in high-stress and high-pressure applications such as pressure vessels, boilers, and structural steel.

Full penetration butt weld

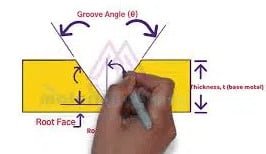

The butt joint is the most common type of joint used in welding and is defined as two parts that are placed together end to end and are welded together.

A full penetration butt weld is a type of weld in which the weld metal completely fills the entire thickness of the base metal at the joint.

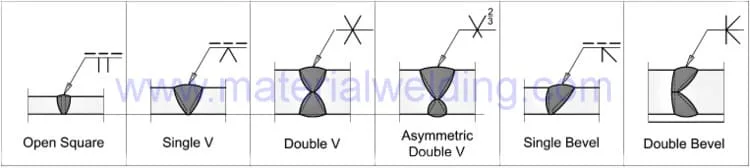

Full penetration butt weld are mainly groove weld (Either single groove or double groove) without weld backing welded either from one side or by gouging out the root and welding a back weld run.

Full penetration weld Joint Strength

Full penetration welds are known for their high joint strength and reliability. This is because they provide a complete fusion of the two metal parts being joined together, creating a strong, homogenous bond. T

his complete fusion is possible because the weld penetrates through the entire thickness of the metal parts, rather than just the surfaces as in the case of fillet welds.

The strength of a full penetration weld is determined by several factors, including:

- Free from welding defects especially those create notch effect,

- Quality of the weld,

- Inclusion of 100% surface & volumetric NDT.

- Thickness of the metal parts being joined,

- Type of material being welded.

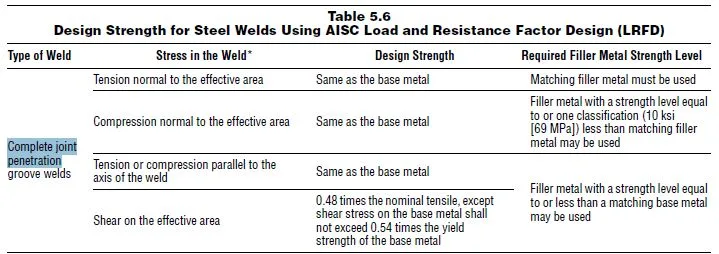

Design Strength for full penetration welds in steel using AISC load & Resistance factor design (LRFD) is given below (Reference: AWS Handbook):

In addition to their strength, full penetration welds are also known for their resistance to fatigue and stress corrosion cracking.

Presence of welding undercut, incomplete weld penetration or crack reduces the fatigue strength of full penetration welds.

Full penetration welding symbol

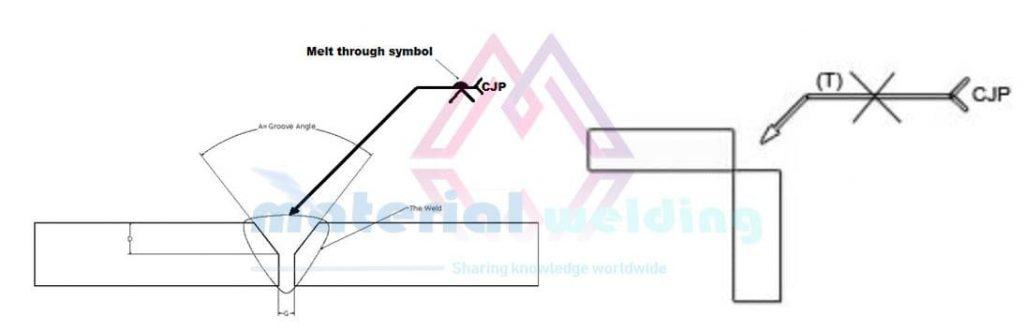

The full penetration weld symbol is a set of symbols used in welding blueprints and drawings to indicate the type of weld being used and the specific requirements for that weld.

A full penetration weld is designated as “CJP” in the welding symbol tail section to specify that it is a full penetration welding joint as shown in the below figure. Sometimes, it is also specified as complete penetration or Full penetration weld in tail of welding symbol instead of “CJP”.

Full penetration butt weld symbol

The full penetration butt weld symbol is a variation of the standard full penetration weld symbol, specifically used to indicate that the weld being used is a full penetration butt weld.

See below example of Full penetration butt weld symbol on left hand side. Right side picture shows weld symbol for a corner full penetration weld.

The full penetration butt weld symbol is composed of a reference line, an arrow and a weld symbol.

The tail section is used to specify that it is a full penetration butt weld by indicating as “CJP”.

full penetration fillet weld

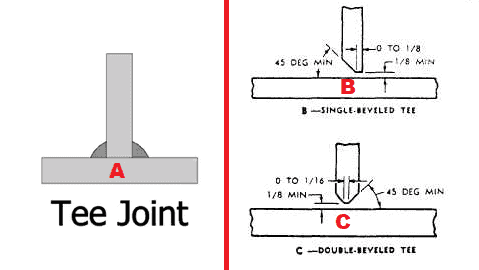

Fillet welds can not be full penetration weld. The right word is Tee-Joint full penetration weld.

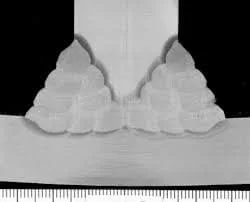

A T-joint with full penetration involves a groove in the vertical member and welded with a root gap or back gouged to achieve the full penetration joint.

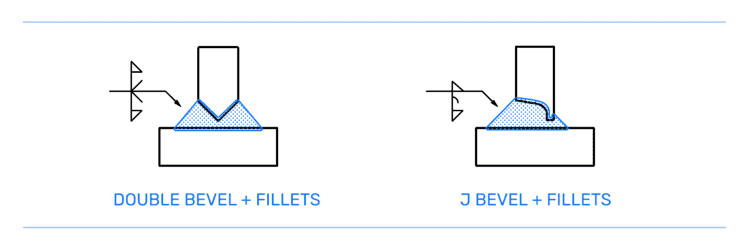

The weld may have an additional fillet weld welded on it. In EN 15085-3, these welds are called HV weld, where HV stands for Half-V.

Full penetration fillet weld symbol

Example of HV weld is shown in the below figure Right hand side. HV weld is similar to Fillet weld configuration but with added weld bevel and root gap to facitilate fill penetration weld.

symbol, specifically used to indicate that the fillet weld being used is a full penetration fillet weld with example is shown below.

A full penetration fillet weld is a type of fillet weld that extends through the entire thickness of the base metal at a joint, creating a complete and uniform bond between the two pieces of metal.

Full penetration weld vs fillet weld

A Fillet weld is a type of welding that is used to join two pieces of metal at a 90-degree angle.

The weld is typically triangular in shape, and it is used to join two pieces of metal that are in a T-shape or an L-shape configuration.

Fillet welds are used in a variety of applications, including in construction, welding of pipes, and in the manufacture of machinery.

A full penetration weld, on the other hand, is a type of welding that is used to join two pieces of metal at a 180-degree angle.

The weld is typically a groove shape, and it is used to join two pieces of metal that are in a butt joint configuration.

A full penetration weld is typically used in high-stress applications, such as in the welding of pipelines, pressure vessels, and in the fabrication of heavy machinery.

The main difference between the two is that a fillet weld is only partial penetration, it only joins the surfaces of the metal parts together and a full penetration weld goes through the entire thickness of the metal parts creating a more secure bond.

It is also worth noting that full penetration butt welds are typically stronger and more reliable than fillet welds, and they are therefore used in applications where safety and high-stress loads are a concern.