When you are working in Welding & fabrication field, it is very important to know the basics of Important Weld Joint Types.

“Tee Joint Welding or also called T-Joint is the most basic welding joint type used in almost all welding fabrication jobs.”

In this article, I have explained in depth What is Tee Joint welding (T-Joint), its types, Tee Joint weld preparation, welding difficulties, and design concerns.

Tee Joint Welding Definition

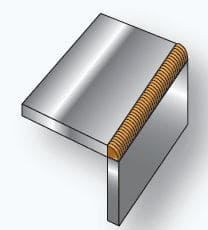

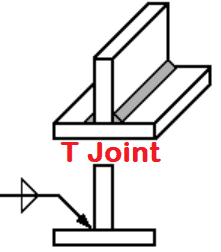

A tee joint welding is a type of welding where two joining members of metal are welded at right angles (90 degree angle) to each other and forming a T-shape configuration.

Tee joint allows for the joining of two pieces at right angles and with no gaps or overlap between them. This joint is formed by placing the two pieces at right angles, forming a ‘T’ shape when viewed from the end.

Tee Joint Types

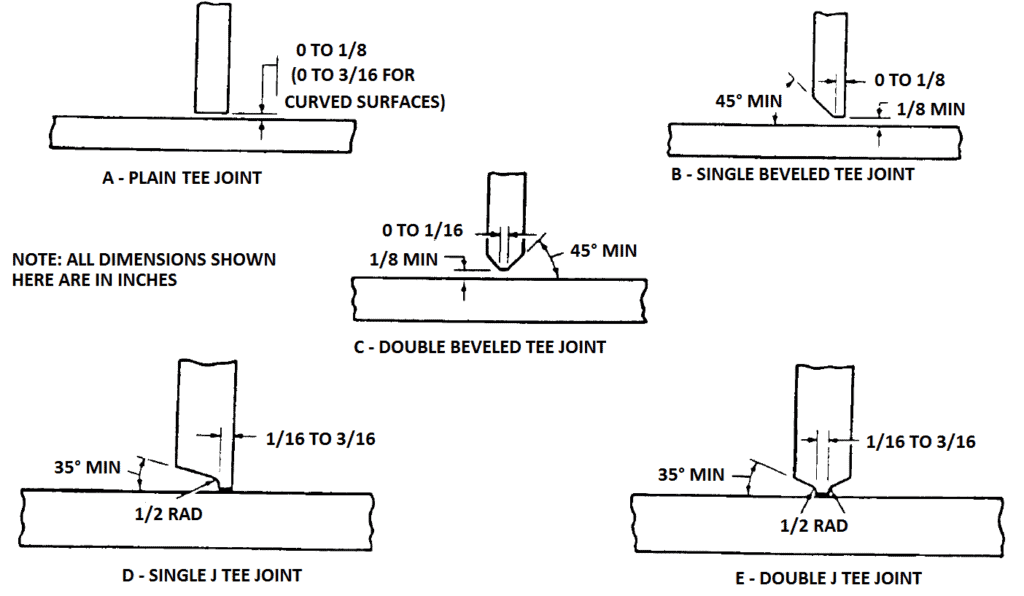

Depending on the strength needed, there are different types of tee joint welds that can be used. The main types of Tee-Joints are:

- Plain Tee-Joint,

- Single Beveled Tee-Joint,

- Double Beveled Tee-Joint,

- Single-J Tee Joint,

- Double-J Tee Joint.

Welding Strength of a Tee Joint Welding

tee joint welding is a type of welding commonly used in metal fabrication that creates an overlap between two pieces of material at 90 degrees to each other.

Tee Joint (T-Joint) type of joint is strong and widely used in many applications where strength and reliability are essential.

Read more: Fillet Weld, Its Types with Welding Symbols.

The strength of the weld depends on several factors including the quality and thickness of the metals being held together, as well as the specific welding technique used. To achieve optimum strength for a tee joint weld, it’s important to select high-quality materials with appropriate thicknesses for the application at hand.

Additionally, proper preparation and cleaning prior to welding are essential to ensure a secure bond between the pieces being joined together.

Tee Joint Weld Preparation Types

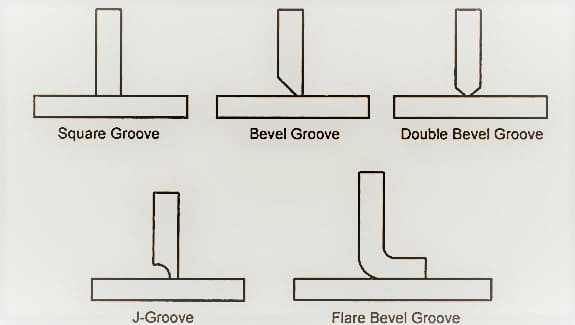

Tee joint weld preparation types tend to vary depending on the material being welded, as well as the application. The most common type of tee joint are the:

- Plain Tee-Joint,

- Single Beveled Tee-Joint,

- Double Beveled Tee-Joint,

- Single-J Tee Joint,

- Double-J Tee Joint.

Tee Welding Joints defined in EN 15085-3 are having following types:

- Tee Joint without weld preparation.

- HY Joint. (Partial weld penetration- PJP type).

- HV Joint. (Full penetration weld- CJP type).

Tee Joint Welding Issues

Tee joint welding is a common and important part of many fabrication processes. However, it is not without its difficulties.

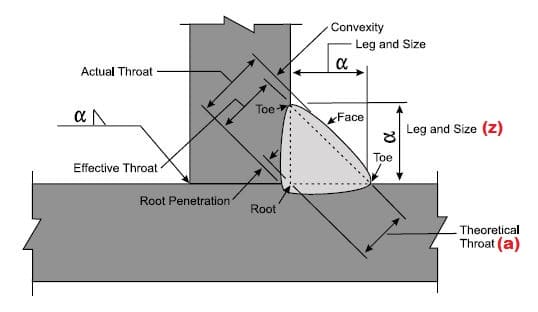

Tee joint welds can be highly susceptible to issues such as lack of penetration, excessive convexity, weld asymmetry and porosity, which can lead to poor structural integrity and weak connections in the final product. It’s important for welders to understand why these issues occur, in order to prevent them from happening in the first place.

The common welding issues assoicated with Tee joint welding are:

- Lack of root penetration,

- Insufficient fillet weld size,

- Excessive convexity of concavity,

- Excessive weld asymmetry of the weld.

- Lamellar Tearing.

Read more about Welding Defects, types, and their remedies in my this article.

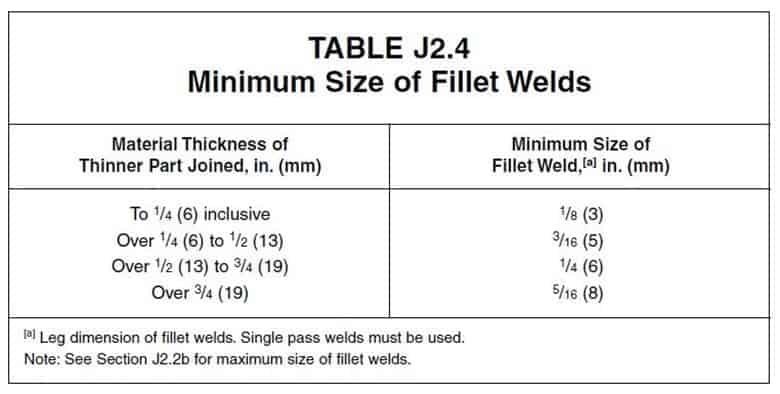

What should be the minimum weld size for a Tee Joint Welding?

When it comes to welding, a minimum weld size is essential for ensuring the quality of the welded joint. The size of the weld should be determined by the material thickness, which determines how much penetration and reinforcement is needed in order to form a secure Tee Joint Welding.

Below is the minimum T- Weld joint size required as per AWS D1.1 code.

Generally, a Tee Joint Welding’s minimum weld size should be between 0.25-0.375 inches (6-10 millimeters) or 0.7t where ”t” is the thickness of the base metal.

When welding thicker materials, such as steel plates that are over 1″ thick (25mm), it will typically require an increase in the weld size for proper reinforcement and penetration.

It is also important to consider other factors such as filler metal type and deposition rate when determining suitable minimum weld sizes for different types of Tee Joint Weldings.

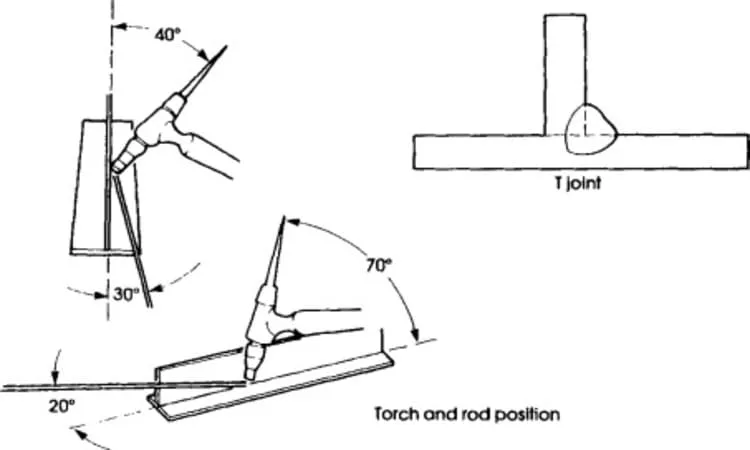

Tee Joint Welding Procedure

Tee joint welding is a common welding technique used to join two pieces of metal at a 90-degree angle.

The following is a general procedure for welding a tee joint:

- Prepare the joint by cleaning the surfaces to be welded and removing any rust, paint, or other debris.

- Clamp the two pieces of metal together so that they are held securely in place. Use right-angle to check the joint alignment and tack weld the plates.

- Set the welding machine to the appropriate settings for the type and thickness of metal being used.

- Begin welding at the top of the joint, working your way down one side, across the bottom, and up the other side. Use a consistent and steady motion to create an even bead of weld.

- Inspect the joint for any defects or inconsistencies and make any necessary repairs.

- Allow the joint to cool completely before removing the clamps and handling the welded pieces.

What types of metal can be used for tee joint welding?

Tee joint welding can be used on a variety of metal types, including carbon steel, stainless steel, aluminum, and titanium.

Can a tee joint be welded from one side only?

Tee joints can be welded from one side, but it is generally recommended to weld from both sides for a stronger and more secure joint.

What is the minimum thickness of metal that can be used for a tee joint welding?

The minimum thickness of metal that can be used for a tee joint welding will depend on the welding method and equipment being used, as well as the experience and skill of the welder.

How to inspect a tee joint welding?

The most common way to inspect a tee joint welding is visually, by looking for signs of cracking, porosity, and incomplete fusion.

Other methods include Non-destructive testing such as Magnetic particle testing and Dye penetrant testing can also be used for surface inspection of Tee-joints.