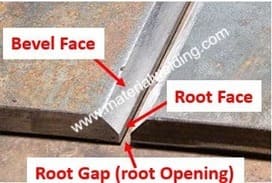

Edge Joint Welding refers to the welding of a joint configuration where two or more plates are placed parallel to each other and welded on the full plate thickness edges. The edges of both members to be welded are even.

Edge Weld as you notice in the below figure is neither a Fillet Weld nor a Groove Weld but instead similar to surface weld. While a surfacing weld is done on a material surface, Edge Joint differs to a surface weld as it joint two members together.

Edge Joint Definition

An edge joint is a type of welding joint in which the two pieces of metal to be joined are placed side by side and welded along their edges.

This is in contrast to butt joints, in which the two pieces are placed end to end and welded along their faces. Edge joints are often used when welding sheet metal, as they allow for a cleaner, more aesthetically pleasing weld than a butt joint.

The edge joint is one of the basic weld joints out of the main 5 joint types. Generally, edge joints are welded only on one side and hence not as strong as butt welds & groove welds.

Related reading: Types of Welds and Weld Joint with their Welding Symbols

Edge Joint Welding

Edge joint welding is used to join two pieces of metal together at their edges. This type of weld can be used on both flat and curved surfaces.

There are several things to keep in mind when edge joint welding, such as the type of metal being used and the thickness of the metal.

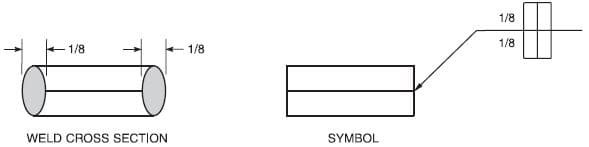

Edge Joint Welding Symbol- Weld Callout

An Edge Joint welding symbol is used to give an edge weld on the welding joint. The edge joint welding symbol is the same for all three types of edge joints.

The weld symbol for edge weld is placed on the reference line and has significance or arrow side (placed below the reference line) or other side welds (placed above the reference line).

An edge welding symbol with a plain edge joint weld configuration is shown in the below figure.

The welded side is placed on the left side of the edge weld symbol and if the length of the weld is specified it is given on the right side of the weld symbol.

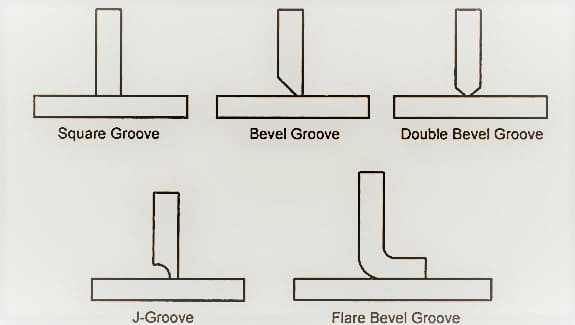

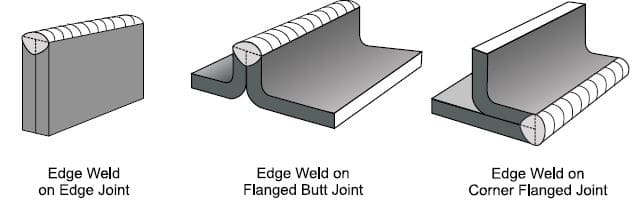

Edge Joint Types with diagram

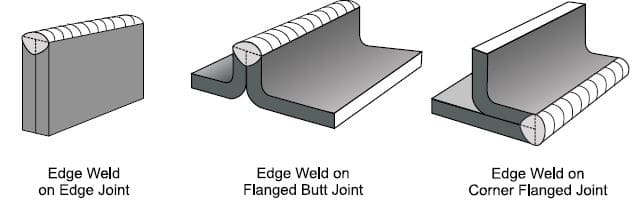

There are three types of edge welds:

- Edge weld on an edge joint,

- Edge weld on a flanged butt joint, and

- Edge Weld on corner flanged Joint.

The most common type of edge weld is the edge weld on an edge joint. This type of weld is made by welding two pieces of metal together at their edges.

The other two types of edge welds are less common, but they are still used in some applications.

The edge weld on a flanged butt joint is made by welding two pieces of metal together at their edges. The two metals have a flanged edge shape (formed by bending).

The corner flanged is made by welding two pieces of metal together at their edges and one member as flat while the other is a flanged edge shape.

Edge Joint uses

Edge joint welding is used to join two pieces of metal together at the edges. This type of welding is often used for joining sheet metal or thin plates.

The main advantage of edge joint welding is that it can be done very quickly and easily.

The main Edge Joint uses are:

- Welding of sheet metal

- Reinforcing plate welding in flanges

- Joining two angles, square pipes on structures.

- Welding of mufflers.

Edge to Edge Joint

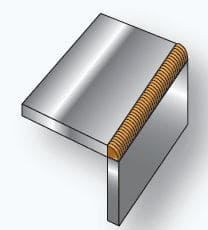

An edge-to-edge joint is a type of welding joint where the two pieces of metal being joined are placed flush with each other, creating a weld-like surfacing weld. This type of joint is often used when joining sheet metal or thin plates.

Edge Joint Welding examples

Edge Joint Welding examples are:

- Edge weld on an edge joint,

- Edge weld on a flanged butt joint, and

- Edge Weld on corner flanged Joint.

These types of Edge Weld examples are shown in the below diagram.

Edge Joint Welding Procedure

Edge joint welding is a common technique used to weld together two pieces that have a flat or L-shaped (flanged shape). This type of welding is often used to connect metal plates and sheets.

- The first step in edge joint welding is to clean the surfaces that will be joined together.

- Once the surfaces are clean, they should be clamped together. This will help ensure that the welded joint is strong and doesn’t have any gaps.

- Carry out the tack welds to hold both members together and even the surface.

- Carry out the full welding equal to the thickness of both plates. As a thumb rule, make sure the weld bead width is equal to the width of the edge joint.

- Refer fabrication drawing for any additional weld requirements.