How to read Weld Symbols?

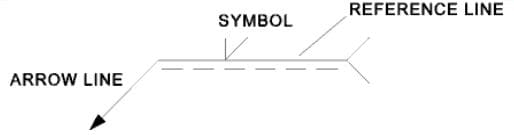

Weld symbols are a key part of welding documentation, and understanding How to read Weld Symbols is critical for welders. There are three main elements to a weld symbol:

- Reference line,

- Arrow Line, and the

- Tail.

The reference line is a horizontal line that is used to align the other elements of the symbol. The arrow is used to point to the location of the weld, and the tail contains information about the type of weld, size, and other details.

Weld symbols can be simple or complex, depending on the information they need to convey. However, all weld symbols follow the same basic format. By understanding how to read weld symbols, you can ensure that you are accurately interpreting welding documentation.

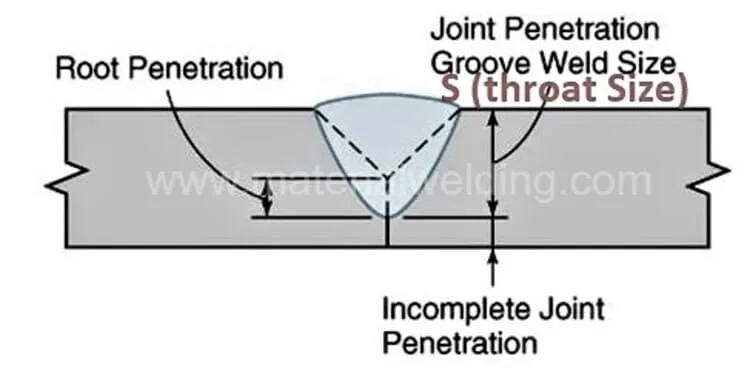

Welding symbols are the integral part and the basic requirements for fabrication as they provide vital information for the welding joint location, weld size (throat or leg length, depth of penetration) & length, weld type & quality requirements for the fabrication or construction drawing.

AWS 2.1 DC: Welding Symbol Chart (desk Size)

AWS 2.1 WC: Welding Symbol Chart (Wall Size)

Difference between Welding Symbol & Weld Symbol

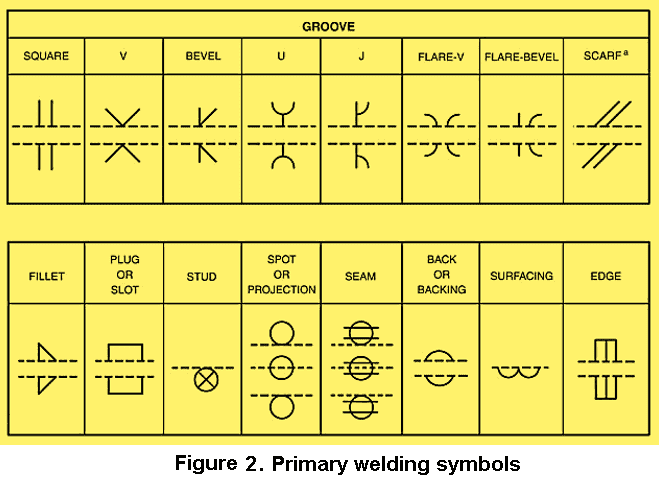

Welding Symbol & Weld Symbol are 2 different terminologies. A weld symbol is a pictorial profile that is attached to the reference line part of the Welding Symbol. A weld Symbol defines the type of geometry for the welding joint. E.g. a Fillet Weld, a bevel or square butt, etc.

A Welding Symbol is partial without a Weld Symbol. So, Weld Symbol supplements a Welding Symbol to provide full details about the welding requirements.

So basically, the weld symbol is a part of the welding symbol. A full welding symbol is made of an arrow line, reference line, & welding symbol. Knowing how to read welding symbols thus depend on understanding this clearly.

A tail is an optional part of the welding symbol used to provide additional information which might be deemed necessary for the production of the welding joint.

What is the Symbol for Welding?

In welding symbol terminology, a clear understanding of the following three terms is very important:

- Primary Welding symbols

- Supplementary symbols

- Welding symbols placement

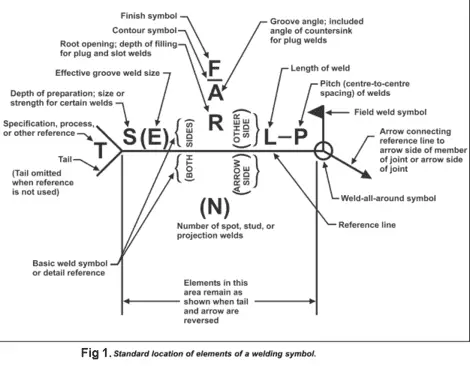

Figure 1 shows the master chart of the welding symbol showing the standard location of elements of a welding symbol.

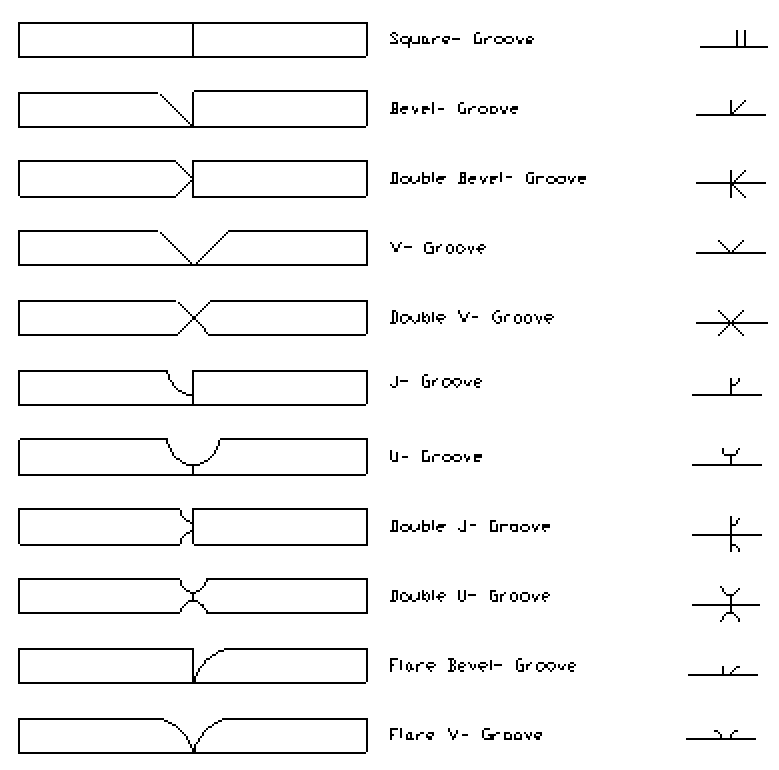

As stated earlier, Weld Symbol is a term used explicitly to designate a specific type of weld. The pertinent types of welds considered under the governing AWS A 2.4 specification for ‘Symbols for welding, brazing and non-destructive examination’ and the basic weld symbols are shown in figure-2.

Primary and Supplementary Welding Symbols

Click Here to Download Welding Symbol Chart in pdf Format.

Watch our interactive learning video for free online training on Welding Symbols:

In contrast to the weld symbol, Welding Symbol provides comprehensive information with respect to the geometry of preparation, fit-up, and welding of joints.

It is composed of standard elements including a weld symbol, arrow line, and reference line, and uses any of the applicable supplementary symbols to effectively complement such information using the help of a tail.

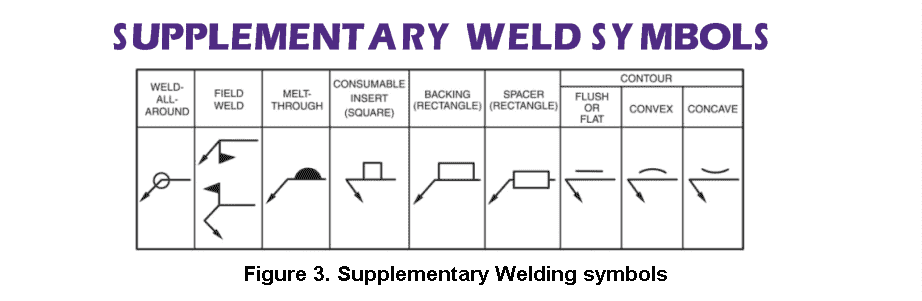

The important supplementary welding symbols are shown in below figure 2.

Understanding Welding symbols in Drawing

We notice Welding Symbols in fabrication & engineering drawings where lines and special geometrical shapes such as triangles, circles, etc. are used to give details about the weld type, weld size, & other supportive information such as welding process, surface finish requirements, etc.

The complete details about the welding symbols are issued by the AWS i.e. American Welding Society standard AWS Series A2.4: Welding & NDT Symbols.

The other Internationally recognized standard for welding symbols is ISO 2553: Welding and allied processes — Symbolic representation on drawings — Welded joints. ISO 2553 is similar to AWS A2.4 with some differences.

Click here to learn the Differences between AWS A2.4 & ISO 2553.

A basic welding symbol for understanding is given below that covers the main part of a complete welding symbol as per AWS A2.4 Standard.

The welding symbols’ main element is the horizontal line. It is the heart of a welding symbol as all other types of welding symbols are connected to the reference line by placing them (e.g. weld symbol, contour symbols) on it or connecting (e.g. tail, field weld symbol, arrow line) further to it.

Details about welding size, length, etc. are placed on this reference line. As shown in the above sketch, the arrow line point to the place where welding has to be made.

Any other information related to welding such as type of welding process, electrode type or NDT method, etc. is placed on the tail area of the welding symbol.

Supplementary welding symbols as we will learn further in this post are also placed on the reference line on the primary weld symbol.

The main parts/ elements of the Welding Symbol

A complete Welding symbol may consist of additional information apart from the 3 main elements listed above. So, a welding symbol can have the following elements:

- A reference Line

- An arrow

- A tail

- Basic weld symbol

- Dimensions and other data

- Supplementary symbols

- Finish symbol

- Specification, welding process type, or any other references for additional information is given in the tail section.

Welding Symbol Reference Line meaning

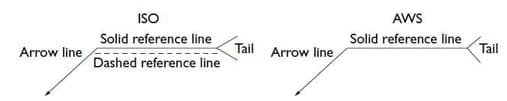

The welding symbols are placed on a horizontal line that is connected to the arrow line pointed at the place of the weld. This horizontal line is called Reference Line. The tail of a welding symbol if used is connected to the other end of the reference line as shown in the below picture.

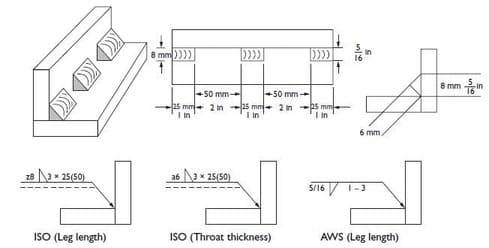

In this example, a weld symbol reference line comparison is given for ISO 2553 Standard & AWS A2.4 standard welding symbols. Here, you can notice that the AWS A2.4 uses only one solid reference line while the ISO 2553 uses two horizontal reference lines- solid & dotted.

All the weld symbols, weld sizes, pitch, and weld length are placed on the reference line part of the welding symbol. The placement of these weld symbols on the reference line further elaborates on the welding directions- Arrow side, or Other side, as explained further in this post.

Arrow Side or Other Side Welding

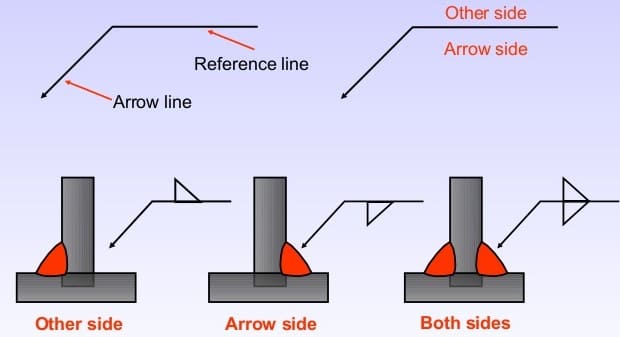

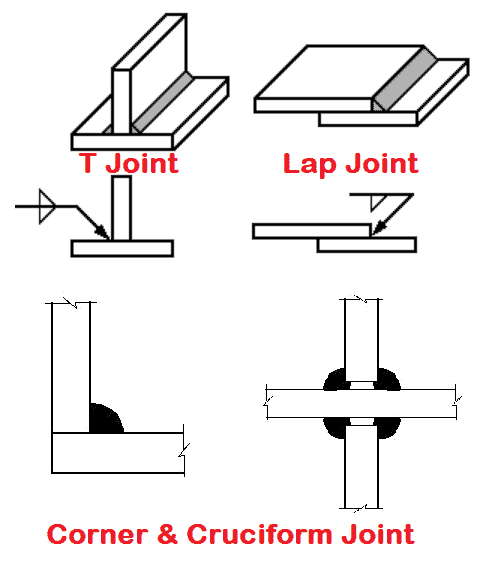

The meaning of arrow and other side refers to the weld placement as indicated by the arrow-line of the welding symbol.

We usually notice in fabrication drawings that there can be a weld on two sides of the welding joint. And the welding symbol may point to any one of them as shown below.

Consider below an example of the ‘T joint‘ shown below, the weld can be on any side of the welding joint or it can be on both sides.

We can differentiate the side or direction of the weld where the weld should be placed with the help of a welding symbol.

As we learned, the arrow line of the welding symbol points toward the area where welding has to be done. The side or direction of the weld joint where the arrow is positioned is known as the Arrow Side & the opposite side of the arrow point is known as the Other Side.

CLICK HERE FOR THE ADVANCED WELDING SYMBOLS

As per the AWS A2.4 standards, The welding needs to be carried out on the arrow side, in case the weld symbol is drawn under the reference line as drawn in the above sketch.

Opposite to that, if the weld symbol is drawn on top of the reference line, welding needs to be carried out on the opposite side of the arrow, known as other side as reflected in the above welding symbol example.

You may notice, that weld symbols on both sides of the reference line, in this case, welding, will be on both sides of the joint and there will no issue of arrow side or another side welding.

Fillet weld symbol

A fillet weld symbol is represented by an insolence triangle placed on the reference line. The weld size (Leg length or throat size) is always given on the triangle’s left side while the nos. of weld or weld length is given on the right side of the relevant weld symbol.

In the below example, the fillet weld symbol as per ISO 2553 and AWS A2.4 are shown.

The application of fillet welds in different types of weld configurations is shown in the below figure for reference.

In a Fillet Weld Symbol, the weld length is specified on the right side of the welding symbol, while the weld size is specified on the left-hand side of the weld symbol always as we can see in the below figure.

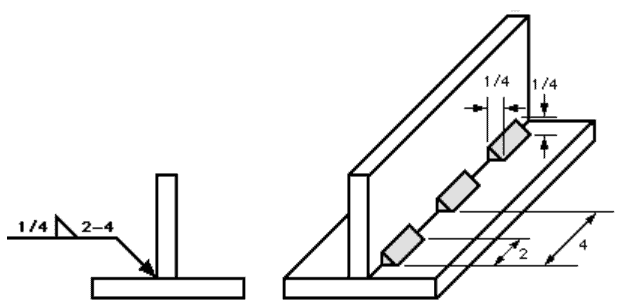

Welding Symbol for Stick Weld/ Intermittent Weld

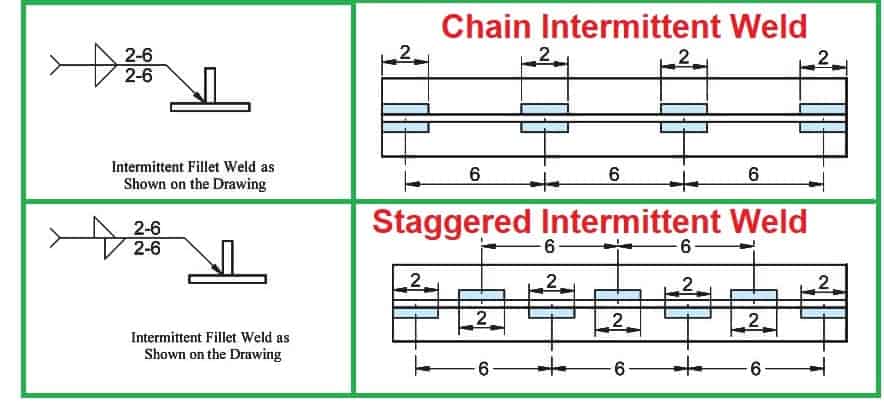

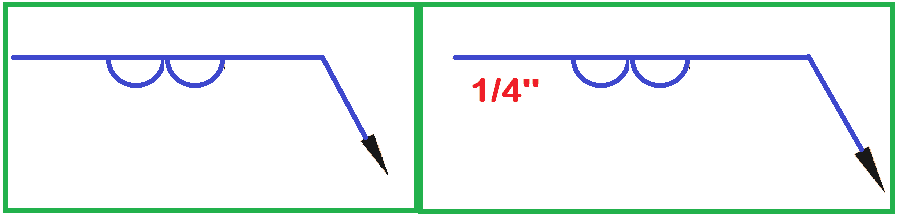

In the below sketch, a symbol of the intermittent weld (also called stitch weld) is shown. In intermittent welds, welds are not continuous and each part of the weld & the space between these welds are split using a dash (e.g. 2-4 in the below symbol) where the first digit shows the weld length and the 2nd digit means spacing between the intermittent welds.

The spacing ( weld pitch) is usually the distance between the weld centers as shown in the below figure for intermittent fillet weld.

If a weld in a joint is to be intermittent ( or Stich weld), the length of the weld and the space between the welds are placed on the right side of the weld symbol is shown in the below welding symbol.

Alternatively, the length of the weld and the pitch (i.e. weld center to weld center spacing) are placed on the right side of the weld symbol.

Chain Intermittent and Staggered (zag-zag) Fillet weld

The main difference between a staggered (zig-zag) intermittent fillet & chain intermittent fillet weld has based on the placement of welds.

For a chain intermittent fillet weld, welds are placed at the same location on both sides of the joint, while in a staggered or also called zig-zag fillet weld, welds are placed on alternate sides as shown in the below sketch.

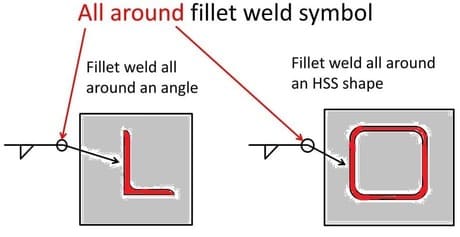

All around Welding Symbol

A weld that extends completely around a joint is indicated by the weld-all-around symbol. The open circle at the arrow/reference line junction is present if the weld is to go all around the joint, as in the example below. The all-around welding symbol should not be used if more than one type of weld is required to make a joint.

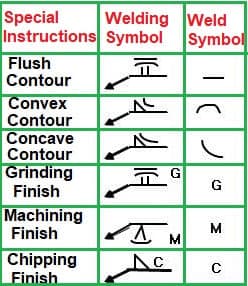

Welding Symbols for grind flush & Contour weld

A contour weld symbol is a supplementary weld symbol as explained earlier used on a welding symbol to indicate the shape of the finished weld.

Welds that are to be made approximately convex, concave or flat without subsequent finishing are represented by attaching the convex, concave, or flush, contour symbol on the main weld symbol as shown in the below figure for various possible contour welding symbols.

Welds that require finishing by mechanical methods are depicted by putting both the appropriate contour symbol (e.g. concave/ convex/ flat) and the required finish symbol (C, M, or G) to the weld symbol.

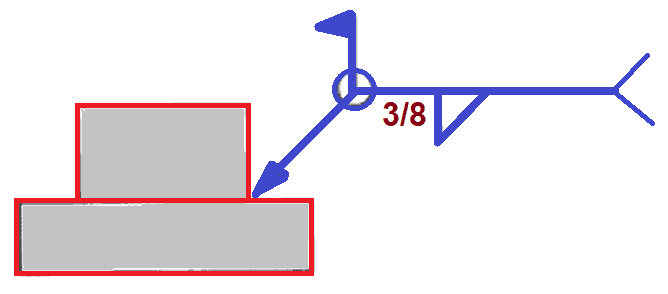

Welding Symbol for Field weld

Field welds are made at the erection site, not in the welding shop. Each of these welds is designed by a field weld symbol ( represented by a flag on the welding symbol) which is always placed above the reference line at its junction with an arrow end pointed away from the arrow towards the tail as shown in the below picture.

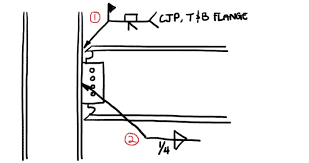

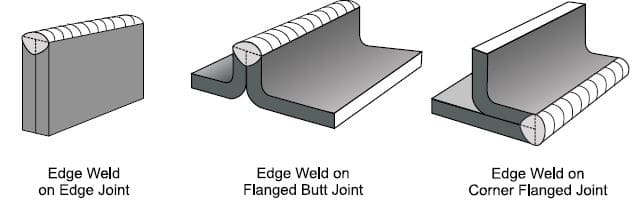

Groove (Butt) Welds on drawing

A groove weld or butt weld is used when two parts come together in the same plane. These welds are applied in a butt joint and may have a preparation (e.g. V groove, U groove, etc.) or not (Square groove) before welding.

Various types of groove welds and their welding symbols (add arrow line when drawing in a drawing) used on the drawing are shown in the below figure.

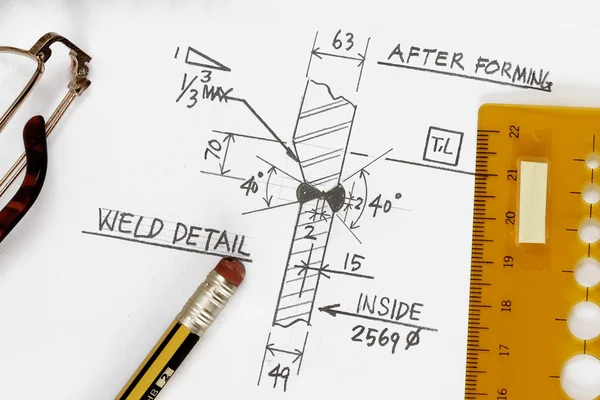

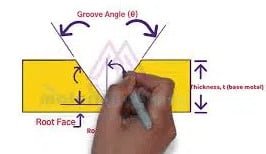

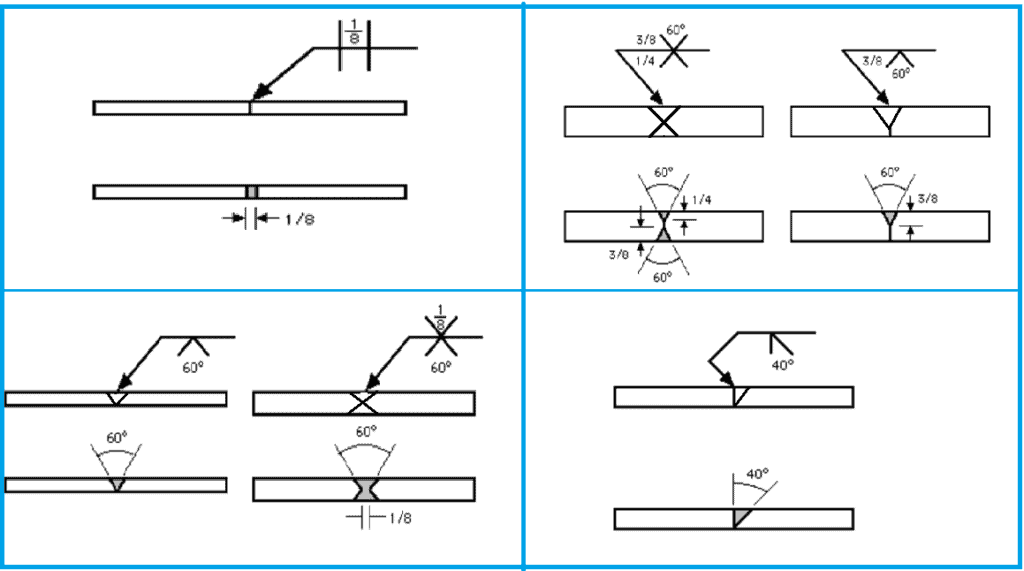

Dimensions of a groove weld

Dimensions of a groove weld are width, depth, and weld length, they are represented by weld groove angle, depth of weld bevel, root face & length of the weld. The width of the groove is the distance between the edges of the weld.

The depth is the distance from the surface of the base metal to the root.

Learn What is Weld Groove, Its main elements & types

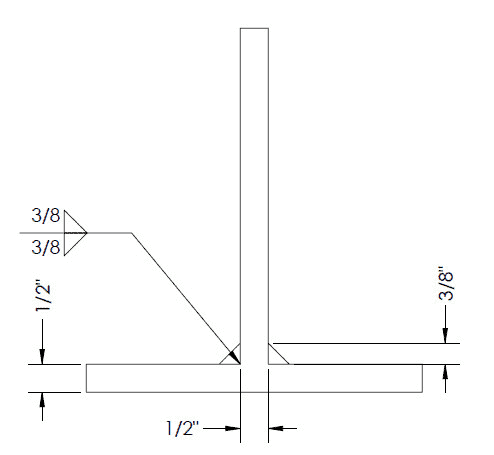

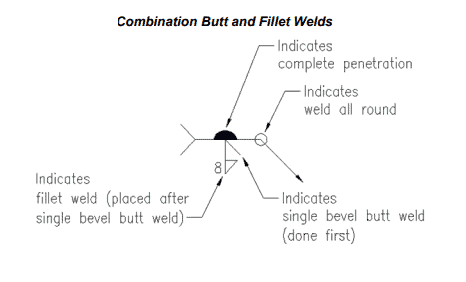

Combined Fillet and Groove weld symbol

A combined fillet, groove weld symbol is shown in the below diagram. The groove weld shall be welded first followed by the Fillet weld. The weld has to be done all around as per the symbol.

A combined weld symbol represents a different type of weld (Weld symbols) shown with a single welding symbol. For example, a T joint has a groove weld followed by a fillet weld and an additional fillet weld on the other side.

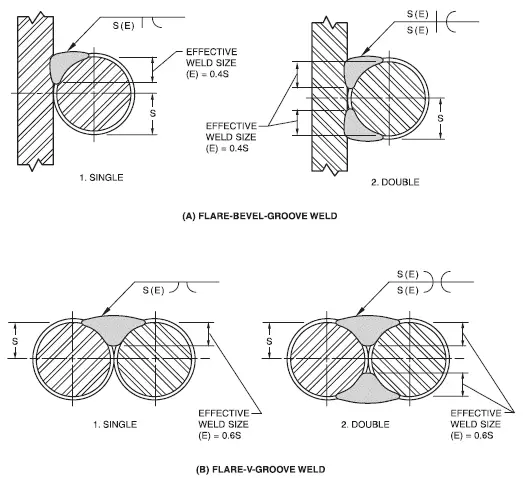

Flare V Groove and bevel groove weld Joint

Flare V type Groove weld joints are usually made to weld two circular or curved components for example joining of two pipes as shown below. The welding symbol of a flare V groove is shown on the below-left side. The required depth of flare groove is placed on the left side of the weld symbol and the depth of welding is given in brackets.

Flare Bevel type Groove weld is used to weld a circular part on a flat surface such as a plate. Similar to a flare V Groove, the required depth of the flare groove is placed on the left side of the weld symbol, and the depth of welding is given in brackets.

A perpendicular line in the flare bevel groove is always placed on the left side and the flare symbol on the right side. Flare bevel and Flare V groove type joints are used mostly in structural parts fabricated according to AWS D1.1 for example.

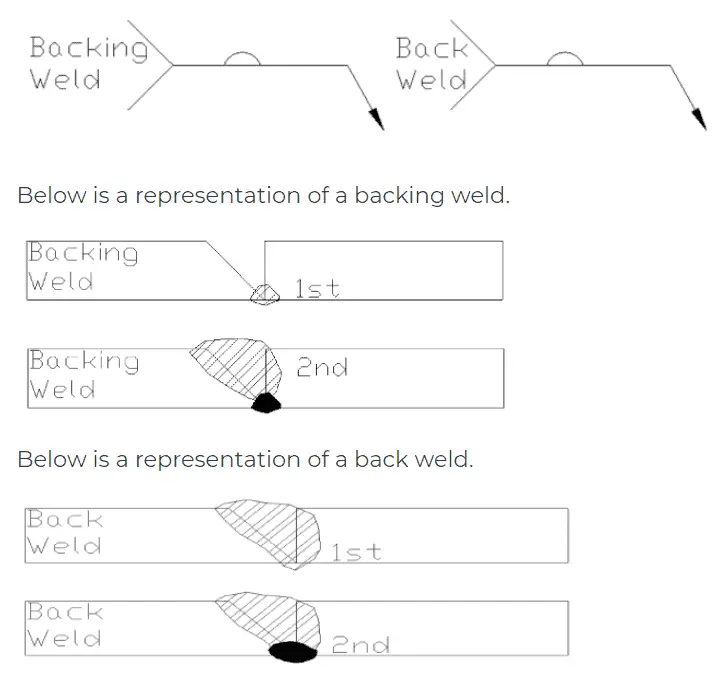

Back, Backing weld, Surfacing weld

You will notice at many places in fabrication drawings where it is mentioned as a back weld or a backing weld. Back welds are backing welds- both are the same having the same weld symbol and hence not to be confused. Sometimes additional information is specified in the tail section of the welding symbol.

Back welds are placed after welding/ finishing a V groove. The weld root is grinded/ gouged and a single pass weld is placed to ensure full root fusion to achieve a complete penetration weld (CJP). Back weld sometimes is also called sealing run.

Based on the welding symbol, a backing weld may be welded before filling the groove to avoid melt-through when welding the groove.

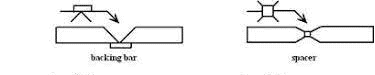

Backing and spacer welding symbol

A backing symbol is placed above or below the reference line to indicate that a backing ring, strip, or consumable insert is applied in making the weld.

It must be used in combination with a groove weld symbol to avoid mix-up with a plug or a slot weld. An ‘R’ may be put inside the backing symbol if the backing shall be removed after welding. The backing type, material, and dimensions are usually given in the tail part of the welding symbol.

Surfacing Weld Symbol

Surfacing weld or weld built-up or buttering or hard-facing or corrosion resistance overlay (CRO) is the type of weld that is deposited on the material for various reasons.

For example, CRO is applied on low-cost material using an exotic material to increase corrosion resistance- such as applying stainless steel welds on carbon steel surface or applying a hard material layer on a softer material.

So the surfacing welds have many objectives. Surfacing weld can have a single pass or multipass & in addition, to a multi-layer weld deposit.

The welding symbol of a surfacing weld is shown below. The size of a surfacing weld represents the height of the weld deposit and is placed always on the left side of the weld symbol.

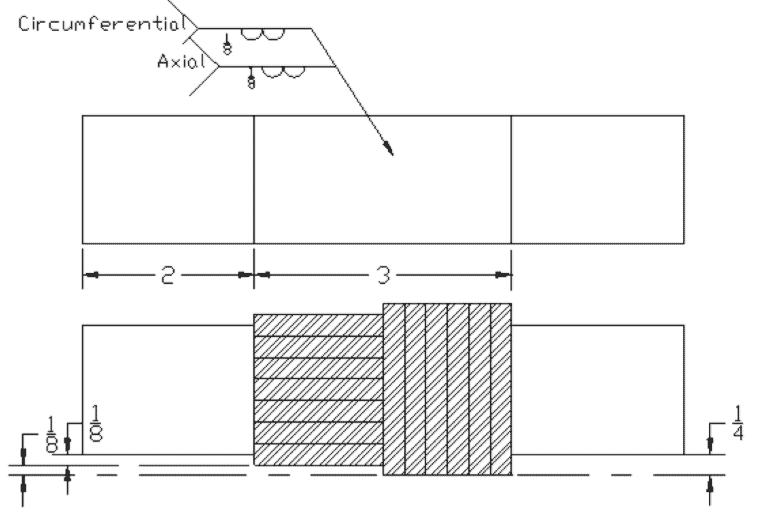

Surfacing weld direction (longitudinal or transverse or circumferential) if applicable is presented in the tail section of the welding symbol. In the example below, the first layer of weld deposit is carried our axial followed by 2nd layer deposited in the circumferential direction. 1/8 means the height of the surface weld.