Importance of CJP, PJP joints & applicable Welding Codes.

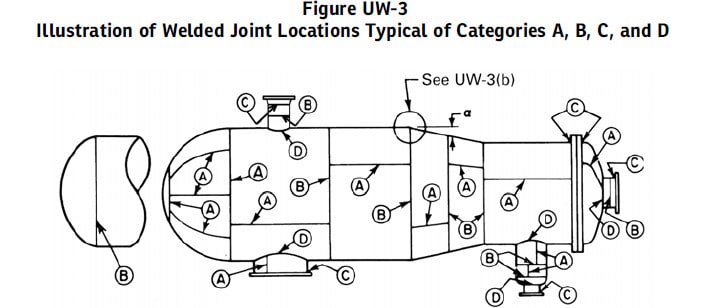

CJP & PJP welding joints are defined in AWS D1.1, D1.5 & CSA W59 welding codes and are applicable for structural welding only as other welding construction codes such as ASME Section-VIII, Section-I, B31.3, API-1104, or ISO welding standards does not use this term.

This article covers what is CJP, PJP, their welding symbols, Inspection requirements, differences between CJP & PJP, and design details.

What is CJP weld joint & CJP weld meaning?

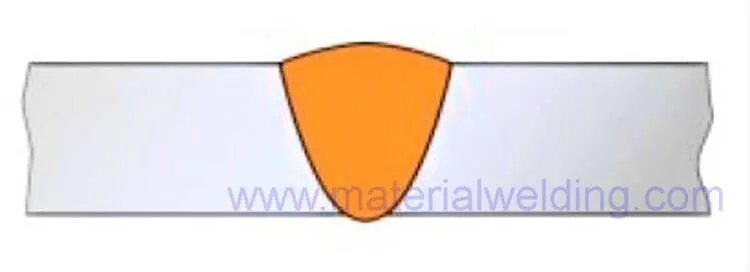

CJP means Complete Joint Penetration (also called Full Penetration weld).

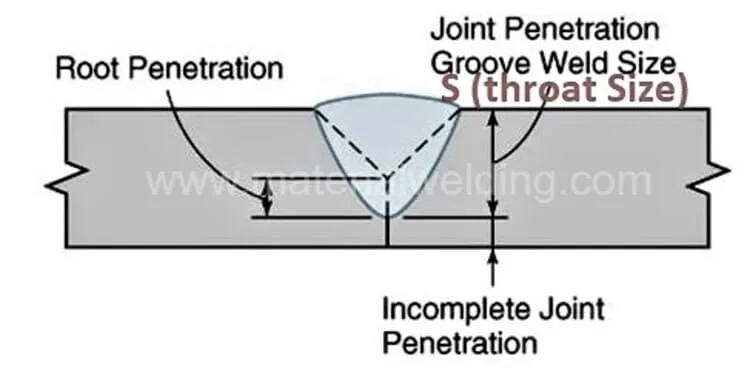

So, CJP refers to welding joints made in groove joints or T-joints where weld metal is deposited from root to base metal face and extends throughout the base metal thickness with visible penetration in the root.

Are you in Welding? Check out these Welding Inspection Tools.

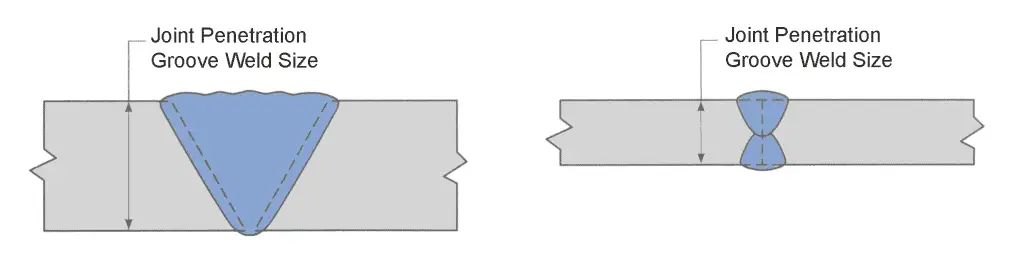

Complete penetration is a non-standard term for CJP weld. A simple explanation of CJP is given in the below picture for a CJP weld in the groove joint.

The depth of groove including a bevel face is considered for dimensioning of the complete joint penetration (CJP) weld and called weld throat size.

AWS D1.1 and CSA 59 have classified the CJP weld into two types:

- CJP groove weld (Applicable for statically & cyclically loaded parts).

- CJP groove weld (Applicable for tubular parts).

Type 1- CJP Weld: Type-1 Complete Joint Penetration (CJP) Welds are made by welding from both sides. For example, a single V-groove is welded from one side and then back-gouged and welded from the root side to achieve a full penetration weld.

A weld made with a backing strip or backing plate to ensure the full fusion of both plates with the root backing is also a Type 1 CJP weld.

Type 2- CJP Weld: Type-2 CJP-weld is applicable for tubular connections. The weld can be made from both sides or single side weld (mostly used for smaller diameter tubular sections where root-side access is not possible).

Read more: Difference between ISO 2553 and AWS D1.1 welding symbols!

What is PJP weld joint & & PJP weld meaning?

“PJP” Means Partial Joint Penetration. Due to the welding being done from one side, the partial penetration groove welds (PJPG) are most often executed when there are certain circumstances.

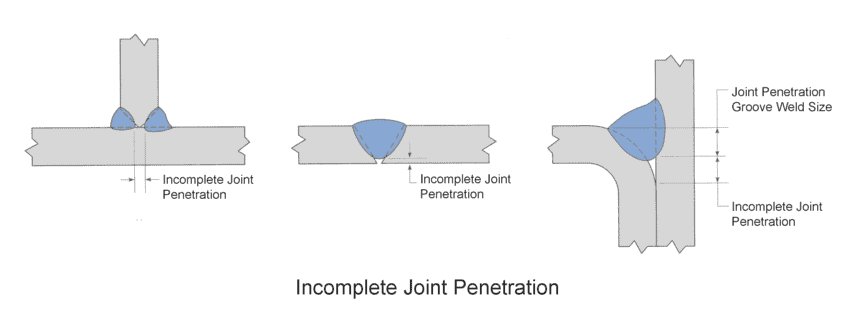

In PJP weld, the weld penetration is intentionally kept partial as shown in below different PJP weld joint configurations for T-Joint, groove, and flare joint configuration. In PJP welds, the weld penetration does not reach out to the weld root and the weld throat size (S) is always less than the base metal thickness.

CJP and PJP weld symbol

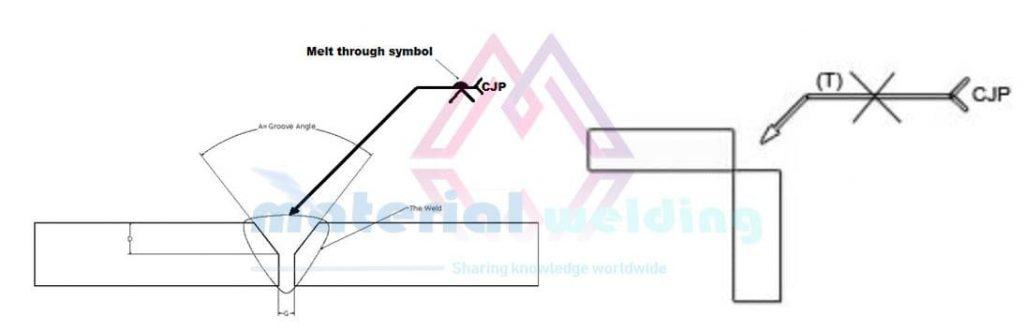

CJP weld joint must be clearly identified on the welding drawing. As per AWS D1.1 or CSA 59, the tail part of the welding symbol shall mention the joint type as ‘CJP’ as shown in the below welding symbol example for reference.

The important requirement for CJP is that is not mandatory to specify the weld symbol (e.g. single V or double V) but the designer can simply call out CJP in the tail location. Then this is up to the contractor/fabricator to choose the best possible joint type.

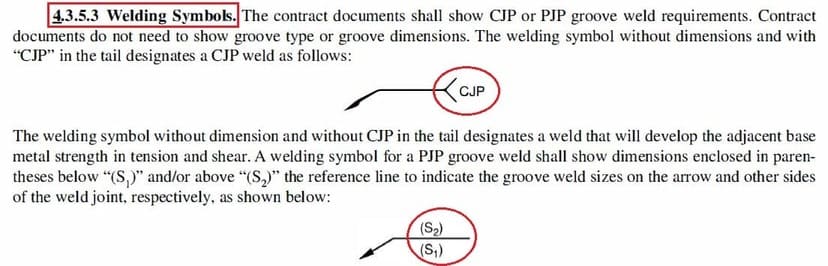

The welding symbol requirements for CJP and PJP welds are specified in AWS D1.1, Clause 4.3.5.3, and given below for reference. It is not mandatory to specify PJP in the tail as required for CJP weld. But the weld symbol shall specify the weld dimensions (S- throat size) for the PJP weld.

CJP weld vs. PJP weld

With the above information, you are now familiar with both CJP and PJP weld types.

To summarize it: CJP means Complete Joint Penetration while PJP Means Partial Joint Penetration. In CJP weld, the weld penetrates from the top of the base metal to the root while in PJP weld, the weld penetration is restricted within the base metal to a pre-defined dimension.

For example- 1-inch penetration in a 2-inches plate joint. So, the dimension of a ‘PJP weld’ is 1-inch only while if we assume it is a ‘CJP weld’, the weld dimensions will be 2-inches i.e. equal to the base metal thickness.

| Characteristic | CJP Weld | PJP Weld |

|---|---|---|

| Joint Strength | High | Lower |

| Welding Time | Longer | Shorter |

| Cost | Higher | Lower |

| Welding Difficulty | More Difficult | Easier |

| Welding Preparation | More Preparation Required | Less Preparation Required |

| Weld Appearance | Often Poorer Appearance | Better Appearance |

| Weld Penetration | Goes Through Entire Thickness of Material | Only Partial Penetration |

| Joint Thickness | Suitable for Thicker Materials | Suitable for Thinner Materials |

| Weld Quality | High-Quality Weld with No Cracks or Voids | May Have Cracks or Voids |

| Applications | Heavy Duty and Critical Applications | Light to Moderate Duty Applications |

Read more: Rule Of Thumb For determining the Fillet Weld Size

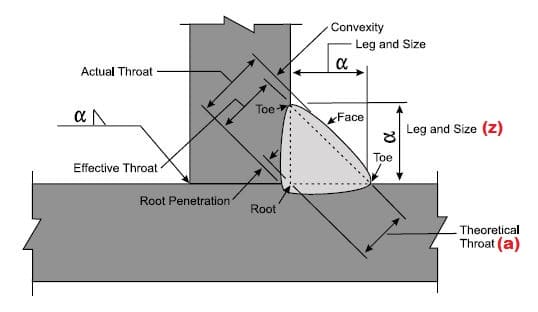

CJP weld vs. Fillet Weld

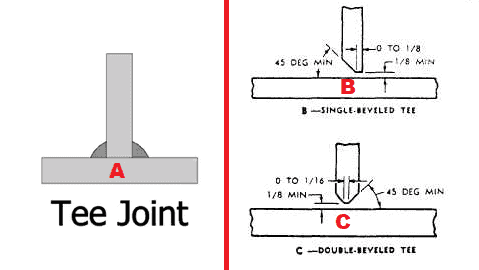

First, we must be clear about the differences between a Fillet Weld and T joint. A T-joint is a weld configuration where 1 joining member is horizontal & another is perpendicular.

Refer to example ‘A’ below. So, in a Fillet weld (A type of T-joint)- two members are joined but not completely fused as there is always an unfused butt area between these members.

On other hand, A CJP weld can be either a T-Joint as shown in the below example- B & C or can be a groove weld as discussed earlier. So, a T-Joint can also be a CJP weld depending upon its weld preparation.

Fillet welds are not as strong as CJP welds. While CJP welds are designed for load carrying applications, most of the fillet welds are used for joining purposes only or limited shear load applications.

In addition, CJP welds require higher NDT inspection by UT (e.g. in the case of T-K-Y welds) while fillet welds are inspected by visual inspection only.

CJP weld preparation

Weld preparation is crucial in the case of complete joint penetration (CJP) welds. Most of the fabrication drawings as per AWS D1.1 mention only CJP in the welding symbol tail section & give freedom to the fabricator to choose a suitable weld joint type.

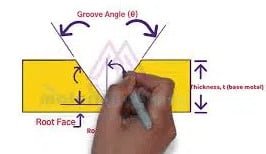

Consider the following main concerns when preparing CJP weld:

- Ensure there is sufficient root gap in groove-joint or T-Joint for full penetration.

- Avoid large root faces as they can cause a lack of root fusion.

- If required refer to AWS D1.1/ CSA 59 for recommended weld joint types. Refer to AWS D1.1, 5.4.2, 10.9 (PJP), 5.4.1, and 10.10 (CJP) for recommended joint details. Pre-qualified CJP groove joint design details are given in AWS D1.1, figure 5.1.

When referring to prequalified joint as per AWS D1.1, after back gouging it is not possible to achieve the exact same joint configuration. As long as it is feasible to make a full penetration, such situations are acceptable.

CJP Weld vs. full penetration weld

Full penetration weld is a non-standard term used for CJP weld. A CJP weld can be called a full penetration weld as the purpose of both terms is the same. In ISO standards and ASME Standards, there is no specific CJP term instead the joints are referred to as full penetration or partial penetration welds.

CJP Weld without backing

CJP welds can be made with or without backing. Groove welds in tubular connections are usually made without backing as well as all T-K-Y joints too. In the case of T-Joints, the backing is mandatory and provided by the horizontal plate member in the joint configuration itself.

Use of backing is prohibited in CJP weld that is subjected to cyclic transverse tension (fatigue) loading. Any backing if used in such joints shall be removed and the weld root shall be ground consistently.

CJP & PJP weld strength calculation

The effective load-bearing dimension of a CJP weld is the thickness of the base metal. In the case of dissimilar thicknesses, the thickness of the thinner member shall be considered.

The allowable stresses and their ranges and stress calculation are given in AWS D1.1, clause 4.16.

Read more: How to calculate throat size or leg length size in a fillet weld?

CJP Weld Inspection type & requirements

CJP groove weld joints designed for cyclic transverse loading such as T-K-Y joints (cyclic loading due to sea waves) shall be inspected with radiographic Testing (RT) or Ultrasonic Testing (UT) as per AWS D1.1, clause 4.19.

The face & root of the CJP weld shall be inspected visually and free from the crack, inadequate root penetration, and incomplete fusion. The melt-through (excess root penetration) shall not be more than 1/8 inch or 3 mm.

Similarly, root concavity shall be a maximum of 1/16 inches (2 mm) condition that the total weld thickness is more than the base metal thickness.

PJP weld effective throat size

The fabrication drawing of the structural part shall show the depth of the groove (D) and required penetration depth (S). For the acceptance of a PJP weld, then ‘S’ must be equal to or greater than the required size (S).

In CJP weld, the weld penetrates from the top of the base metal to the root while in PJP weld, the weld penetration is restricted within the base metal to a pre-defined dimension.

For example- 1-inch penetration in a 2-inches plate joint. So, the dimension of a ‘PJP weld’ is 1-inch only while if we assume it is a ‘CJP weld’, the weld dimensions will be 2-inches i.e. equal to the base metal thickness.

PJP weld with reinforcing fillet

T-Joints in CJP or PJP joints are made with or without reinforcing fillet weld or additional fillet weld. The reason could be due to design requirements (e.g., peak stress concentration locations) or service concerns (e.g., requiring flush welds to accommodate other parts).

Examples of various such conditions are given in the below sketch.

What is the difference between CJP and PJP welding?

CJP welding is a type of welding in which the weld metal completely fills the joint, resulting in 100% joint penetration. PJP welding, on the other hand, is a type of welding in which the weld metal only partially fills the joint, resulting in less than 100% joint penetration.