What is Hot Start in Welding?

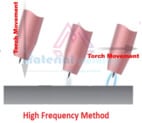

Hot start is a welder feature that helps in easy ignition of the welding arc. It allows for an excellent start to welding by providing higher heat at the weld start, resulting in improved arc stability and good fusion between base metals.

This feature also prevents electrode sticking during start-up by generating higher levels of current than that generated during steady state operation.

When we start welding initially, the base metal is cool and most of initial heat get easily dissipated in base metal. This increases the risk of lack of fusion at weld start point.

If a machine lacks hot start feature, welders need to use backstep welding technique to ensure good weld fusion at weld start point.

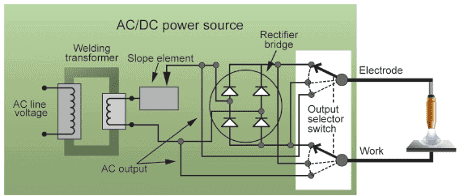

Hot start welding requires specialized equipment; an arc welder with hot start capabilities must be used in order to achieve this desired effect.

The system works by providing additional voltage and current at the initial moment of contact between the electrode and workpiece, allowing for increased heat output during startup.

The technology also employs dynamic temperature control which monitors the welder’s operating conditions and adjusts accordingly to ensure optimal performance throughout each job cycle.

What is Arc Force or Dig or Arc Control in Welding?

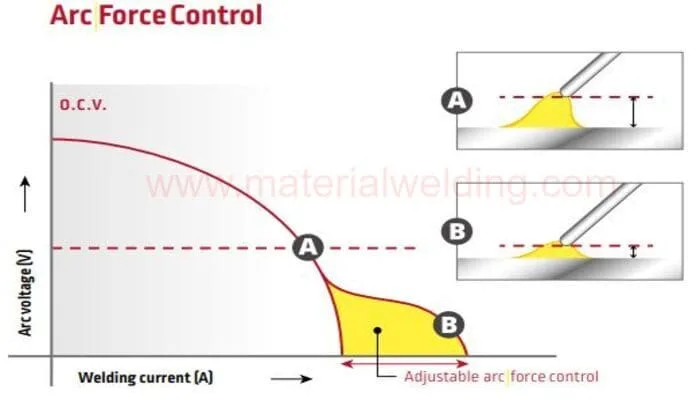

Arc force or Dig or arc control in welding is a welder feature used to maintain a consistent arc length while welding and not just at the start or end of the weld.

It is an automatic temporary voltage-current adjustment system, which can improve weld quality, reduce the chance of burn through and maintain excellent welding arc performance.

The system helps to provide constant arc force during the entire welding process and also compensates for changes in welding current-voltage, by automatically increasing current when necessary.

Arc force works by detecting the arc length when the arc starts to become short and then applying more voltage so that it will remain constant.

This helps to ensure a smoother weld. Additionally, this technology can help reduce spatter in finished welds, resulting in better overall quality.

Arc force or Dig In welding technology is often used in robotic systems where consistency is essential for good results.

What is Anti-Stick feature in welding?

Anti-Stick feature in welding is an important safety measure that prevents welding rods from sticking to the workpiece.

It is an inbuilt feature (without any external control knob) of many modern welders, which cuts power automatically if the electrode were to stick to the job.

The anti-stick feature works by detecting a short circuit between the electrode and workpiece when they are stuck together and then quickly cutting off power before any major damage or welding machine overloading takes place.

This inbuilt feature can be extremely useful in preventing damage to both the welding rod and workpiece, as well as reducing downtime during operations.

The Anti-Stick feature works quickly and efficiently by using sensors within the welding machine to detect when an electrode is sticking, then immediately cutting off power supply until it is removed.

How to set arc force on a welder?

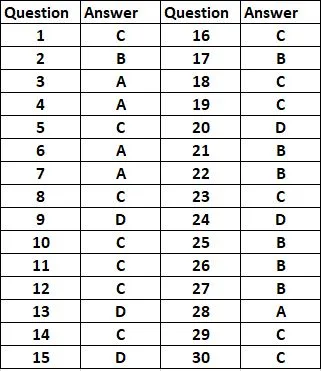

If the arc force feature is available in a welder, you can adjust it by control knob. The value of arc force is usually 0- 10 (“0 to -10” and “0 to +10”) as shown in the picture above.

Higher the arc force setting, more intense the welding arc and hence deeper weld penetration. Arc force function in lincoln machines also help to prevent electrode sticking.

When welding using basic (E7018 or E7016) rods and rutile (E6013) rods, set arc force to lower side (+2- 4) to give you a smooth welding arc with low spatters. In case you want deeper penetration go for higher side (+7-10).

Cellulose electrodes (Such as E6010) already have intense arc, so it is good to keep arc force value low when welding with cellulose rods. When welding fill pass and cap passes, you can use soft arc force (negative side) with cellulose rods.

Read more: Types of Welding Rods and their selection.

How to use hot start feature on a Welder?

Welding is a complex task that requires a lot of skill and precision. To make the process easier, many welders come with a hot start feature which helps to jumpstart the welding arc.

This can be especially helpful when welding thicker metals. The hot start feature works by automatically increasing the electric current at the beginning of the welding operation, thus allowing for an easier arc initiation.

To use this feature, first make sure that your welder has it installed as not all welders have this capability.

Once you’re sure that it’s present, you should set your machine accordingly using the settings provided on its control panel.

Depending on your machine type and manufacturer, you may need to adjust different parameters like wire feed speed, voltage or amperage in order to activate the hot start feature correctly.

Conclusion

In conclusion, Hot Start, Arc Force, and Anti-Stick are all features of modern welding machines that improve the quality of welds.

- Hot Start improves welding startability and can help to reduce the risk of weld fusion at start of- welds.

- Welding arc force help to maintain a constant arc length for superior arc performance and weld quality.

- Anti-Stick prevents electrodes from sticking to the workpiece and prevent damaging the welding machine and weld quality.