Types of Welding Joints

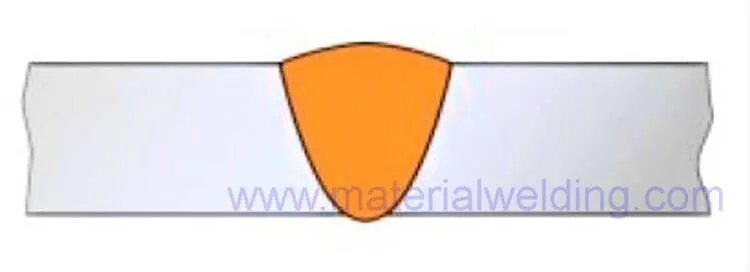

What is Welding Joints: A joint can simply be described as a configuration of members and can be described independently of how it is welded. A butt joint and a T joint are the most common type of weld joint.

What is a Weld:

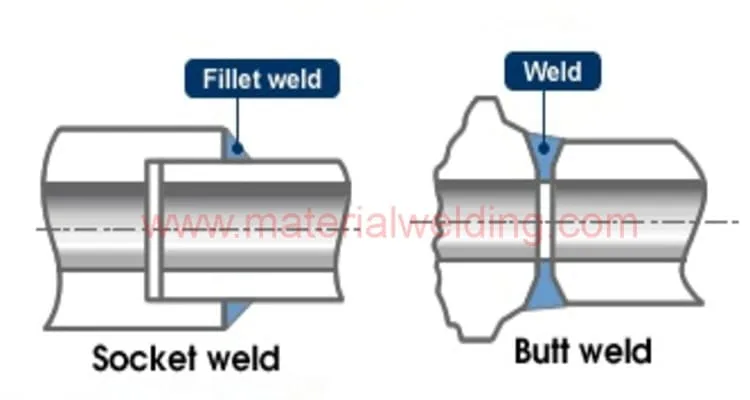

A weld is a permanent union between materials caused by the melting of materials to be joined or by solid diffusion with melting by applying heat or pressure or using both heat & pressure. if this joining is made between two faces approximately parallel, is known as a butt weld.

And a weld made between two faces that are approximately at right angles to each other is known as a fillet weld.

Read more: Welding Joints Symbols

Also check out this website covering basic to detailed information with examples for Welding Symbols.

Types of Welding Joints

The main types of weld joints are:

- Butt Joint

- T Joint

- Corner Joint

- Edge or parallel Joint

- Lap Joint

- Cruciform Joint

- Flare Groove joint

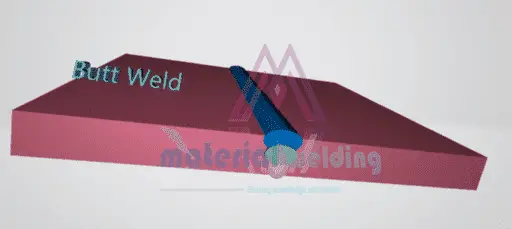

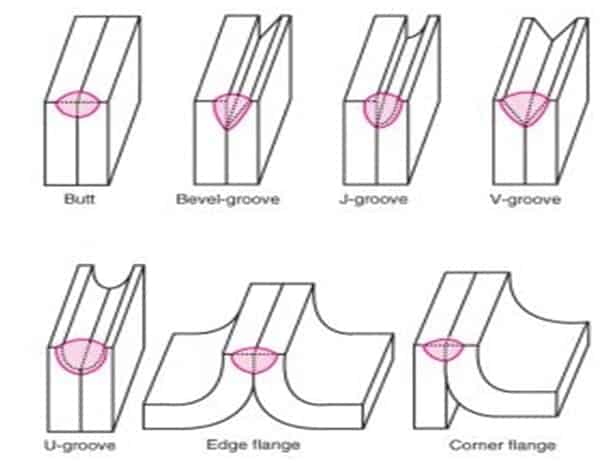

What is a Butt Joint Welding?

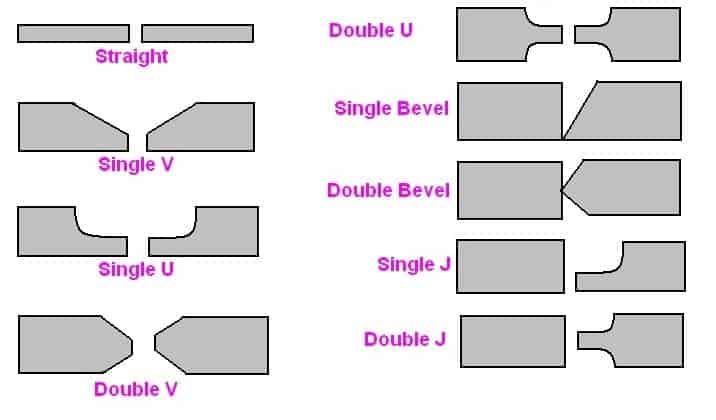

Butt Joint: In this type of joint, two metals are joined by simply placing their ends together and then performing the welding operation. These two objects are nearly parallel and do not overlap. This example shows a single V butt joint.

Here various types of butt joints configurations are shown.

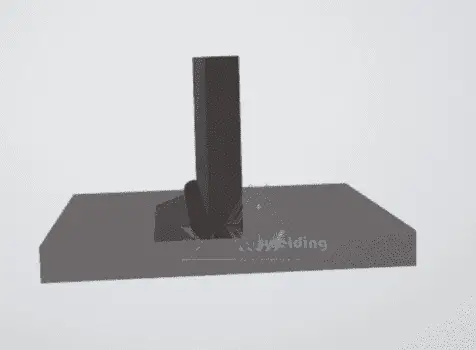

What are T Joints or Fillet welding Joints?

2. T joint or fillet joint is the most common type of welding joint. In a T-Joint, two members are welded to each other as shown in the below figure.

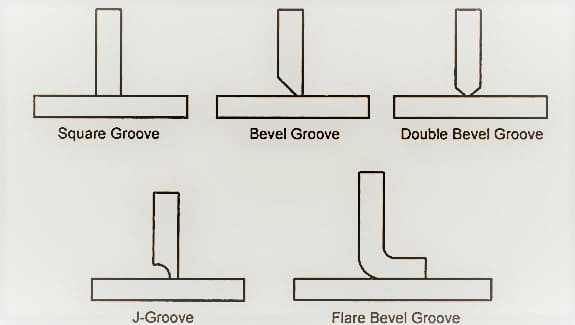

As the name suggests, two plates or pipes are 90 degrees from each other forming the letter T shape. Take your time to get familiar with different types of T joint weld configurations.

Here various types of T-Joint configurations are shown.

What is a Corner Joint?

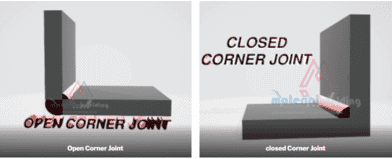

3. Corner Joint: In corner joint configuration, two members are welded to each other at the edges. The angle formed between two members shall be >30° & <135 Degree. The weld appearance in a Corner weld is similar to a T-Joint. They are having two types mainly:

- Closed corner joint

- Open corner joint

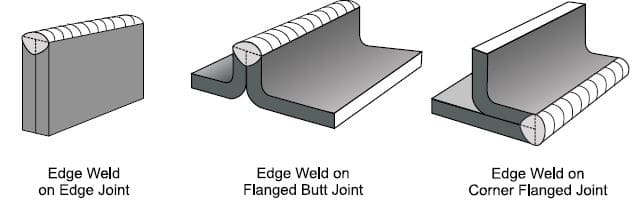

What is an Edge Joint?

4. Edge Joint: An edge joint or simply called parallel joint is a weld joint configuration by laying two-member parallel to each other. Edge welding joints are not very commonly used in structures.

Take your time to get familiar with different types of edge joint weld configurations. shown below:

What is Lap joint?

5. Lap Joint: In a lap joint configuration, two members are laid on each other to overlap and welded using a fillet weld.

When designing lap welding joints, the overlap between the two plates needs to be at least four times the plate thickness, but not less than 25mm. Lap joints are mainly used in Resistance welding (RW) process.

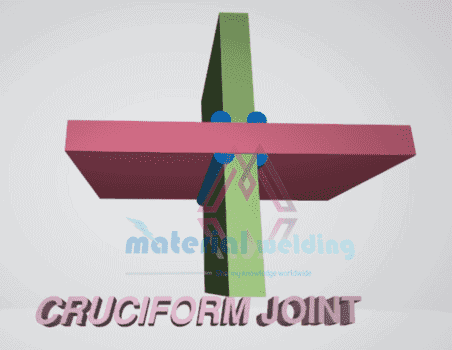

What is Cruciform Joint?

6. Cruciform joint: It is a special type of joint where 3 members are welded at a right angle that appears like a plus sign as shown in the below figure. These joints are used for structural supports, making barriers and other special applications.

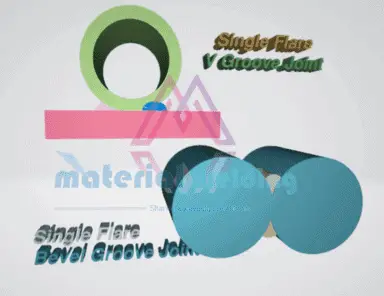

What is a Flare Bevel Joint?

7. Flare Bevel Joint: Flare bevel welding joints are formed between round member or at least one plate member. A simple flare groove joints are shown in below figure.

Skewed Fillet Weld Joint

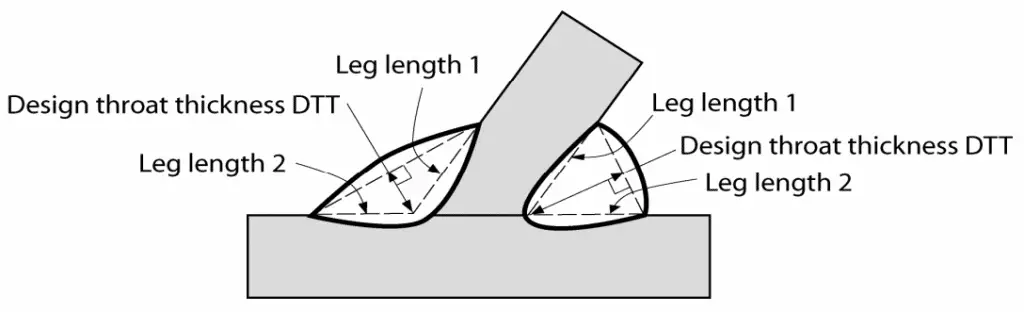

A skewed Fillet Weld Joint is a type of fillet weld or T-joints in which the angle between joined parts is greater than 100° or less than 80° and they are called Skewed T-Joint.

The effective length in case of a skewed welding joints is total length of the fillet weld. The effective throat of a skewed Joint shall be the smallest dimension from the root to the diagrammatic face, less the Z loss reduction distance.

Pre-qualified Skewed T-Joints are specified in AWS D1.1 figure 5.4. For calculation of Effective Throats of Fillet Welds in Skewed T-Joints, examples are given in AWS D1.1 Annex A (Normative).