What is a Circumferential Weld Joint?

A circumferential weld is a type of welding that joins two circular pieces of metal together in a circular fashion. This type of welding is often used to join pipes or other cylindrical objects (e.g., tanks, pressure vessels, columns) together.

A circumferential weld is a type of pipe welding in which the seam is welded around the circumference of the pipe. This type of weld is used to join pipes together, as well as to repair damaged pipes.

There are two main types of circumferential welds:

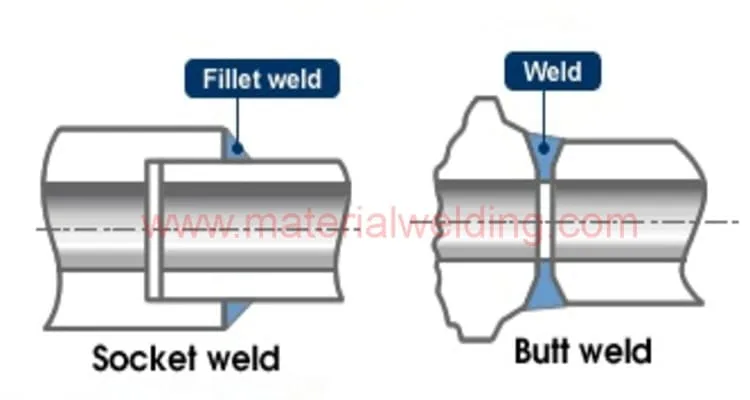

- Butt joints (between two similar diameter pipes)

- Lap joints (between dissimilar pipe diameters).

Butt joints are the most common type of joint used in pipe welding, and they are made by welding the pipe ends together.

Lap joints are made by welding a collar over two pipes, and they are used when it is not possible to butt weld the pipes together such as cement line pipe welding.

Circumferential weld vs Longitudinal weld

Pipelines are commonly manufactured using one of two different types of welding processes- circumferential welds or longitudinal welds.

Which type of welding process is used depends on the type of material being transported through the pipeline and the desired properties of the final product.

Circumferential welds are created by welding around the circumference of a pipe. This type of welding is typically used for high-pressure applications, as it results in a stronger joint than a longitudinal weld. Circumferential welds are also less likely to leak than longitudinal welds.

Longitudinal welds are created by welding along the length of a pipe. This type of welding is typically used for low-pressure applications, as it is not as strong as a circumferential weld. However, longitudinal welds are less likely to cause corrosion in the pipe than circumferential welds.

What is a Girth Weld?

A girth weld is a type of welding that is used to weld two pipes together. It is usually done by welding around the perimeter of the two pieces of metal.

This type of welding is often used for pipelines and other types of large projects. Girth welds are typically stronger than other types of welds, making them ideal for use in high-pressure situations.

Read More: Girth Weld Joint: Everything you need to Know.