Seamless Steel Pipe vs. Welded Pipe: A Comprehensive Comparison

When it comes to choosing between seamless steel pipes and welded pipes, there are several factors to consider, including cost, strength, and application.

Pipes are an essential component in many industrial applications, providing a necessary conduit for liquids and gases.

While steel pipes are the most popular choice due to their durability and cost-effectiveness, there is an ongoing debate on which type of steel pipe offers the best performance: seamlessly constructed or welded?

In this article, we will compare seamless steel pipes and welded pipes in terms of their manufacturing process, properties, and applications, to help you make an informed decision.

Manufacturing Process: Seamless Steel Pipe vs. Welded Pipe

- Seamless steel pipes are made by heating a solid steel billet and then piercing it through with a mandrel to create a hollow pipe. This process is called hot-finished or hot-extrusion.

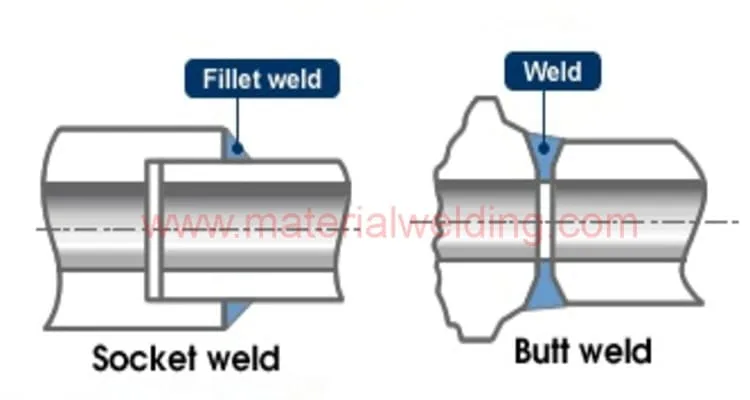

- Welded pipes, on the other hand, are made by welding together two steel plates to create a pipe. This process is called Electric Resistance Welding (ERW) or Spiral Submerged Arc Welding (SSAW).

Properties: Seamless Steel Pipe vs. Welded Pipe

| Property | Seamless Pipe | Welded Pipe |

|---|---|---|

| Strength | Typically, stronger than welded pipes | Typically weaker than seamless pipes |

| Diameter | Can be made in larger diameters | Limited to smaller diameters |

| Surface finish | Better surface finish | Rougher surface finish |

| Cost | Typically more expensive | Typically less expensive |

Main differences: Seamless Steel Pipe vs. Welded Pipe

The key difference between seamless pipe and electrically welded pipe is the method of production. The first option is made from cylindrical semi-finished products.

Changing the shape of a metal blank into pipe rolled products is possible in several ways such as on a special machine, forging, by pressing or drawing.

At the same time, the products are also divided into hot-rolled and cold-rolled. The main advantages of seamless steel pipes include:

- increased strength,

- resistance to negative external factors,

- resistance to the action of aggressive environments.

Electrically welded pipes made of sheet steel or strip. Flat products are given the desired shape, after which the edges of the product are connected using welding.

There are two main varieties of such pipes: straight-seam and spiral. Electrically welded products can be not only round in shape, but also oval, square, rectangular.

Their cost is an order of magnitude lower than that of seamless pipes. Of the advantages of seamless pipe is that they can be used for a wide range and offers long service life.

Applications: Seamless Steel Pipe vs. Welded Pipe

- Seamless steel pipes are typically used in high-pressure applications, such as oil and gas transportation, and are often specified for use in pipelines.

- Welded pipes are used in a variety of applications, including structural and mechanical, as well as for low-pressure liquid transportation.

Related Reading: Types of Pipes ERW, HFW, Seamless, EFW, Spiral and SAW pipe.

Cost: Seamless Steel Pipe vs. Welded Pipe

Seamless steel pipes are typically more expensive than welded pipes due to the more complex manufacturing process and the higher level of precision required.

However, the cost difference may vary depending on the size and grade of the pipe.

Strength: Seamless Steel Pipe vs. Welded Pipe

Seamless steel pipes are typically stronger than welded pipes, as they are made from a solid piece of steel, rather than being welded together.

This also means that seamless pipes are less likely to fail under high pressure.

Service Life: Seamless Steel Pipe vs. Welded Pipe

Seamless steel pipes have a longer service life than welded pipes due to their higher strength and better surface finish. This means that they are less likely to corrode or become damaged over time.

In summary, seamless steel pipes offer higher strength and a better surface finish, but are more expensive than welded pipes.

Welded pipes, on the other hand, are more cost-effective, but may not be as strong or have as smooth a surface finish.

The choice between the two will depend on the specific application and the requirements of the project.

What is the difference between seamless and welded pipes?

This process is called hot-finished or hot-extrusion. Welded pipes, on the other hand, are made by welding together edges of steel plates to create a pipe. This process is called Electric Resistance Welding (ERW) or Spiral Submerged Arc Welding (SSAW).