This article explains the various type of Pipes-we hear with their short-form such as ERW Pipe, HFW Pipe, SAW pipe, and so on, but are not aware of what they mean and how they are manufactured.

Difference between Pipe and Tube

The main differences between pipe and tube are given in the below video.

PIPE vs. TUBE: MAIN DIFFERENCES

What is the Difference Between Seamless and ERW Stainless Steel Pipes?

Electric Resistance Welding (ERW): ERW Pipes are made by using special-purpose machines with inbuilt coil straightener, edge millers, rollers, and resistance welding system.

For making the ERW pipe, sheet metal coils are rolled and longitudinally welded throughout the length using resistance welding.

Compared to ERW, seamless pipes are extruded using the extrusion tools to the required length. the process is repeated until the final dimensions and accuracy is achieved.

You can differentiate between an ERW pipe and a seamless pipe by checking the longitudinal weld seam. A seamless tube is without any welding seam.

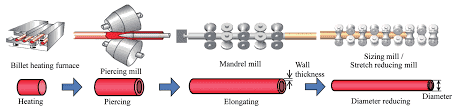

Seamless pipes are manufactured from solid billets by piercing operation and have no weld seams as seen in ERW/ SAW or HFW Pipes.

Seamless pipes/tubes are having accurate dimensional finishes and WT. They are available in sizes from 1/8” to 26” outer diameter.

Seamless piping is used for high-pressure piping systems in oil & gas, power plant, and chemical industries. They are also used for making hydraulic cylinders where pre-honed seamless tubes with high accuracy are used.

ERW Pipe VS. Seamless

You must have come through the situation where you are looking for the answers for “Can I use ERW/HFW or seamless pipes for my job?”.

Both ERW and the seamless pipe have their own advantages and disadvantages. The use depends on the application & availability. Someplace, it is mandatory to use seamless pipe, and in other places, it is ok to use an ERW Pipe.

Below, I have highlighted the main advantages and disadvantages of both ERW and seamless pipes for readers’ understanding.

Seamless Pipes Advantages & disadvantages

- Seamless pipes do not have welding joints and hence provide uniform strength throughout the dimension without any notch or weld reinforcement that could be initiation point for any corrosion or erosion.

- The dimensional accuracy (close tolerances, ovality & roundness, etc.) is higher in seamless pipes compare to ERW pipe.

- The cons of using seamless pipes are the higher cost compare to ERW pipe.

- Due to limited seamless pipe manufacturers compare to the ERW, the delivery time to purchase seamless pipe can be higher.

ERW Pipe Advantages & disadvantages

- ERW Pipes are more economical compare to seamless as their cost is much lower.

- You can get ERW pipes from lot of manufacturers worldwide, hence getting delivery at shorter time is possible.

- As they are manufacturered from sheet, they have consistent wall thickness.

- The main issue of the ERW or welded pipe is the presence of the welding seam, which make them unsuitable for many applications (e.g. you can not use ERW pipe for cylinders where piston need to reciprocate in the bore). This can also reduce the strength of the pipe.

What is ERW Pipe?

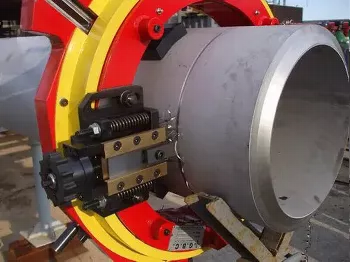

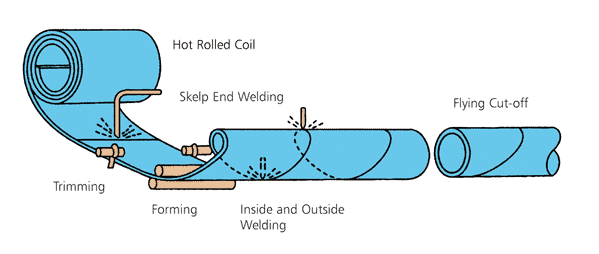

Electric resistance welded pipe or ERW pipe is manufactured from sheet/ plate coil by rolling them and welded using low frequency (ERW) or high frequency (HFW) resistance welding in longitudinal direction using special machine setup as shown in the below picture and explained in the above video.

The process is automated from uncoiling the coils to making the pipe of final dimensions.

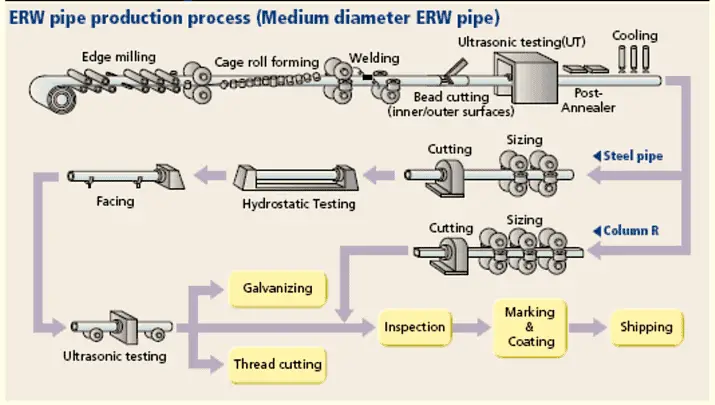

The pipe manufacturing line diagram is shown above. The material coils edges are milled and circular pipe form is given using the continuous rollers followed by resistance welding. Milling tools are used to machine the excessive weld reinforcement.

Heat treatment (such as annealing or normalizing) is incorporated into the production line itself. Finally, the pipes are cut to the required size and dimensions.

Any NDT (such as automated UT) can also be incorporated in the line or can be done later on. ERW pipes are manufactured for diameters up to 24 inches ( 609 millimeters).

- ASTM A 53, A252, A500, EN ISO 10219, API 5L B, X70 PSL1

What is HFW Pipe?

High-Frequency Welded Pipe or HFW Pipe is similar to Electric resistance welded pipe. The main difference is the frequency of welding current.

The meaning of HFW Pipe is High-Frequency Welded pipe.

HFW Pipe manufacturing uses a high-frequency current (usually above 70 kHz). The high-frequency help to faster the manufacturing process as well as give high weld quality compared to ERW pipe manufacturing.

HFW pipes are used for pressurized media such as oil, gas, and water.

HFW Pipe material Standards

API 5L, ASTM A53, A178, A691, A252, EN 10217, ASTM A672 etc.

What is LSAW Pipe (Longitudinal Submerged Arc Welding)

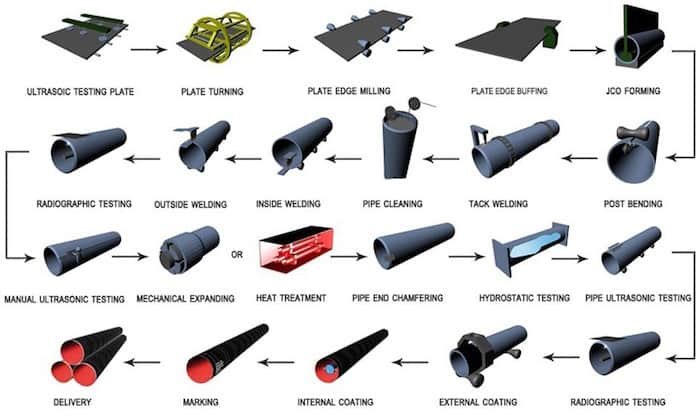

Longitudinal Submerged Arc Welding or LSAW pipes are manufactured using submerged arc welding process as explained in the above video and shown in the below diagram.

Metal plates rolled and welded using a submerged arc welding process. They are mainly made for bigger pipe diameters (Usually above 24 inches and higher).

The types of submerged pipes are:

Full form of SAW Pipe

Full form of SAW Pipe is Submerged arc welded pipe. SAW Pipes are manufactured by two techniques & named as LSAW and SSAW Pipes. Full meaning of LSAW and SSAW are:

- longitudinal submerged arc welded pipe (LSAW)

- Spiral submerged arc welded pipe (SSAW)

EFW Pipe & EFW Pipe Full meaning

EFW Pipe full meaning is Electric Fusion Welding Pipe. EFW Pipe are manufactured by using high electric voltage through the material to melt and weld it.

EFW Pipe manufacturing does not require any extra welding wire. It is an autogenous pipe welding process (you can join same material to itself without adding any additional welding filler). This make is highly suitable to make pipe from 6 inches size to 100 inches size diameter.

EFW vs ERW Pipe

Electric resistance welded (ERW) that uses electric resistance welding principle to weld pipe. The use of ERW is thus limited to low cost and small thickness pipes.

EFW uses high voltage current to generate heat and fuse the pipe material thus making is suitable for welding of thicker diameter and different types of material welding such as stainless steel.

Seamless Pipe vs Welded Pipe

There are many different types of pipes that are used for various purposes. Two of the most popular and commonly used pipes are seamless pipes and welded pipes.

Seamless pipes are made from a single piece of metal, so there is no weak seam that could potentially leak or burst. This makes them ideal for high-pressure applications. Seamless pipes are also more expensive than welded pipes, since they require more time and labor to produce.

Welded pipes, on the other hand, are made by joining together two pieces of metal along a seam. Welded pipes can be less expensive than seamless pipes, since they require less time and labor to produce.

FAQS

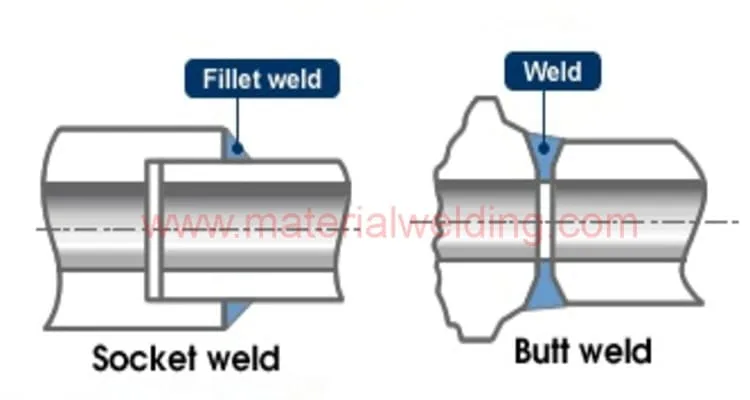

1. What are the Pipeline Seam Type

Pipeline seam types are:

- Longitudinal Pipeline seam: Lengthwise to pipe

- Circumferential Pipeline seam: seam of pipe diameter.

2. Seamless Pipe Meaning

A seamless pipe is a pipe without a seam or a weld-joint. Seamless pipes are thought to be able to withstand higher pressure, higher temperatures, and corrosive environments.

Seamless pipes are made by process of piercing round billets of steel and stretching the steel out into a seamless pipe. This is done using a mandrel where the billet is forced over the top. The billet is then heated until it becomes malleable enough to be stretched out.

3. EFSW Pipe full form

EFSW Pipe stands for Electric fusion seam welded pipe.

4. Full form of SAW Pipe

Full form of SAW Pipe is Submerged arc welded pipe.

5. HFW Pipe Meaning

The meaning of HFW Pipe is High-Frequency Welded pipe.