Codes and Standards for Piping: A Comprehensive Guide

Piping systems are critical components of various industries, including oil and gas, power generation, chemical processing, and water treatment, etc. to name a few but not limited to. Ensuring the safety, reliability, and efficiency of these systems is essential, and this is where codes and standards come into play.

In this blog article, we will explore the various widely used and most important codes and standards applicable to piping systems, their objectives, and their relevance for Engineers and Inspectors.

What are Codes and Standards?

Codes and standards for piping engineering are sets of rules and guidelines established by recognized organizations to ensure the safe and efficient design, fabrication, installation, and operation of piping systems. They provide industry best practices, technical specifications, and testing procedures to ensure that piping systems meet the required levels of performance, safety, and reliability.

Key Organizations Developing Piping Codes and Standards

Several organizations are responsible for developing and maintaining codes and standards for piping systems. Some of the most well-known organizations include:

- American Society of Mechanical Engineers (ASME): ASME is an international organization that develops and maintains a wide range of codes and standards for various engineering disciplines, including piping systems.

- American Petroleum Institute (API): API is a leading organization in the oil and gas industry, responsible for developing and maintaining codes and standards related to the design, fabrication, and operation of pipelines and associated facilities.

- International Organization for Standardization (ISO): ISO is a global organization that develops and publishes international standards for various industries, including piping systems.

- European Committee for Standardization (CEN): CEN is a regional organization responsible for developing and maintaining European standards for various industries, including piping systems.

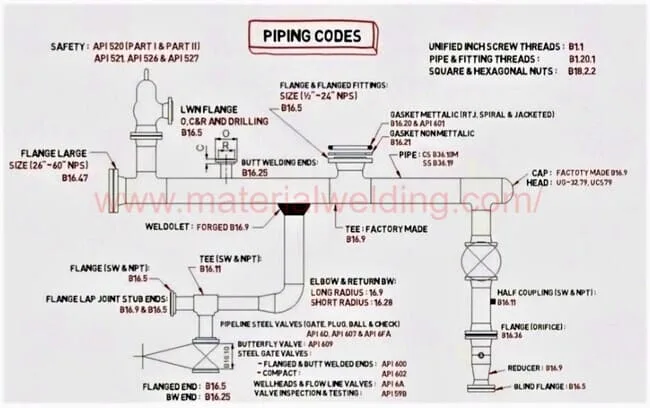

Key Codes and Standards for Piping Systems

Several codes and standards apply to piping systems, depending on their application, materials, and design. Some of the most widely used codes and standards include:

ASME Codes

- ASME B31.1 – Power Piping: This code covers the design, fabrication, installation, inspection, testing, and maintenance of power piping systems used in electric power generating stations, industrial and institutional plants, and district heating systems.

- ASME B31.3 – Process Piping: This code provides requirements for the design, fabrication, installation, testing, and inspection of process piping systems in various industries, including chemical, petroleum, pharmaceutical, and food processing.

- ASME B31.4 – Pipeline Transportation Systems for Liquids and Slurries: This code covers the design, construction, operation, and maintenance of pipeline systems used to transport liquids and slurries, such as crude oil, refined petroleum products, and chemical solutions.

- ASME B31.5 – Refrigeration Piping and Heat Transfer Components: This code provides requirements for the design, fabrication, assembly, testing, and inspection of refrigeration piping systems and heat transfer components. It covers materials, components, and joining methods used in refrigeration systems, including those used in air conditioning, heat pumps, and industrial process cooling.

- ASME B31.8 – Gas Transmission and Distribution Piping Systems: This code provides requirements for the design, fabrication, installation, testing, and maintenance of gas transmission and distribution piping systems, including natural gas, propane, and other fuel gases.

- ASME B31.9 – Building Services Piping: This code covers the design, fabrication, installation, testing, and maintenance of building services piping systems, such as those used for heating, cooling, and water distribution in commercial, institutional, and residential buildings. It addresses systems conveying fluids like steam, hot water, fuel oil, and other non-hazardous fluids.

API Standards

- API 5L – Specification for Line Pipe: This standard specifies the technical requirements for the manufacture of steel pipes used in the oil and gas industry.

- API 570 – Piping Inspection Code: This code provides guidelines for the inspection, rating, repair, and alteration of in-service piping systems in petroleum refineries, chemical processing plants, and related facilities.

ISO Standards

- ISO 14692 – Petroleum and Natural Gas Industries – Glass-Reinforced Plastics (GRP) Piping: This series of standards provides requirements for the design, fabrication, installation, testing, and maintenance of GRP piping systems used in the petroleum and natural gas industries.

- ISO 15649 – Petroleum and Natural Gas Industries – Piping: This standard specifies the requirements for the design, materials, fabrication, installation, testing, and inspection of process piping systems in the petroleum and natural gas industries.

CEN Standards

- EN 13480 – Metallic Industrial Piping: This series of standards covers the design, fabrication, installation, testing, and inspection of metallic industrial piping systems, including pressure vessels, storage tanks, and heat exchangers.

ASTM Standards and Specifications

ASTM International is a leading organization that develops and publishes standards and specifications for various materials, products, and industries, including piping systems. Some notable ASTM standards and specifications relevant to piping include:

- ASTM A53 – Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless: This specification covers seamless and welded black and hot-dipped galvanized steel pipe in nominal sizes for various applications, including structural, pressure, and mechanical purposes.

- ASTM A106 – Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service: This specification covers seamless carbon steel pipe for high-temperature service in nominal sizes and for various applications, such as process piping, power generation, and petrochemical industries.

- ASTM A312 – Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes: This specification covers seamless, straight-seam welded, and heavily cold-worked welded austenitic stainless steel pipe intended for high-temperature and general corrosive service in various industries, including chemical, petrochemical, and power generation.

- ASTM A335 – Standard Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service: This specification covers seamless ferritic alloy-steel pipe for high-temperature service in nominal sizes and for various applications, such as power generation, petrochemical, and process industries.

- ASTM D2513 – Standard Specification for Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings: This specification covers the requirements and test methods for material, workmanship, dimensions, and burst pressure of polyethylene (PE) gas pressure pipes, tubing, and fittings for use in fuel gas mains and services.

Conclusion

Understanding and adhering to the relevant codes and standards for piping systems is essential to ensure their safety, reliability, and efficiency. By familiarizing yourself with the various organizations, codes, and standards applicable to your industry, you can ensure that your piping systems are designed, fabricated, and installed according to the highest standards of quality and performance.