When it comes to ensuring the integrity and safety of welded components, visual inspections play a crucial role. Visual examination allows inspectors to identify surface defects, discontinuities, and other imperfections that may affect the quality of welds.

In the context of welding inspections, the American Society of Mechanical Engineers (ASME) has established codes and standards that provide guidelines for visual acceptance criteria. In this article, we will delve into ASME B31.1 and explore its visual acceptance criteria for nondestructive testing.

ASME B31.1 Overview

ASME B31.1, also known as the Power Piping Code, is a widely recognized industry standard that governs the design, construction, and inspection of power piping systems.

It covers a range of topics, including materials, fabrication, examination, testing, and maintenance of power piping systems. While ASME B31.1 provides detailed guidelines for various aspects of piping, it does not explicitly specify visual acceptance criteria for nondestructive testing.

ASME B31.1 Visual acceptance criteria

The visual examination as per ASME B31.1 must adhere to the guidelines outlined in ASME BPVC, Section V, Article 9. It is necessary to conduct visual inspections during the fabrication and installation of piping components to ensure compliance with design and welding procedure specifications (WPS).

Furthermore, visual examination is essential to verify that all welded joints in pipes and piping components meet the specified acceptance criteria mentioned in or adhere to the imperfection limitations stated in the material specification of the provided pipe or component.

While records of individual examinations are not mandatory, except for the in-process examination, it is recommended to maintain documentation for quality control purposes.

Acceptance criteria for welding defects

Unacceptable indications for acceptance standards are as follows:

- Cracks on the external surface are not permitted.

- Surface undercutting deeper than 1/32 in. (0.8 mm) or encroaching on the minimum required section thickness.

- Surface undercutting on longitudinal butt welds are not permitted.

- Weld reinforcement exceeding the specifications mentioned in Table 127.4.2-1 are not permitted..

- Lack of fusion on the surface are not permitted.

- Incomplete penetration (applies only when the inside surface is easily accessible).

- Linear indications greater than 3/16 in. (5 mm) in length are not permitted.

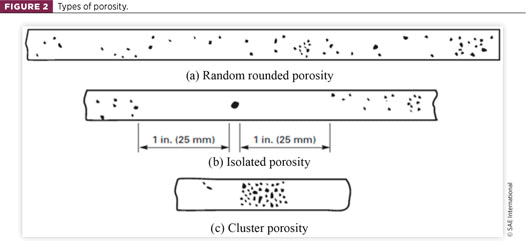

- Surface porosity with rounded indications larger than 3/16 in. (5 mm) or four or more rounded indications that are separated by 1/16 in. (1.5 mm) or less, edge to edge, in any direction.

- Arc strikes outside of the weld joint are not permitted.