Liquid Penetrant Testing -LPT

Liquid Penetrant Testing (PT) is a widely used Nondestructive testing method that can detect surface-breaking discontinuities in nonporous materials. PT uses a penetrant liquid that is applied to the surface of the part under inspection.

The penetrant then seeps into any cracks or other discontinuities in the surface and is drawn back out by a developer. The developer causes the penetrant to form a visible indication on the surface of the part, making any defects easy to see.

Get access to 1500+ ASNT PT Level III Questions-Answers and Free Mock exams

There are two main types of penetrants: Visible Dye penetrants and Fluorescent penetrants.

Dye penetrants are typically red or black in color and fluoresce under ultraviolet light. Fluorescent penetrants are generally more sensitive than dye penetrants and can detect smaller defects, but they are also more expensive.

Acceptance Standards for Liquid Penetrant Testing

Liquid dye penetrant testing is a common nondestructive testing (NDT) method that is used to detect discontinuities in a variety of engineering materials.

The American Society of Mechanical Engineers (ASME) publishes standards for the use of liquid dye penetrant testing, including ASME Section V, Section VIII Division 1, ASME B31.1 & ASME B31.3, etc. which outlines the acceptance criteria for these tests.

In order for a liquid dye penetrant test to be accepted under an acceptance code or standard, it must meet specific requirements with regard to the type of material being tested, the size and location of any defects, and the sensitivity of the test.

If a liquid dye penetrant test does not meet these requirements, it may not be considered reliable and may not be acceptable for use in conjunction with other NDT methods.

The most important standards for Liquid Dye Penetrant testing acceptance are:

- API 1104

- AWS D1.1

- ASME Section VIII Division 1

- ASME B31.1

- ASME B31.3

- ASME Section V

- ASTM E-165

- ISO 3452-1

Relevant Indication in Penetrant Testing

Relevant indication in penetrant testing is the type of indication that exhibit an actual defect in the material being inspected.

For example, in a typical liquid penetrant test for surface defects, indications arising due to penetrant bleed-out are used to identify discontinuities open to the surface.

However, these same indications may not be relevant when inspecting during penetrant testing, e.g. indication due to insufficient cleaning, design holes, shrink-fit parts or any design flaw present on the part.

Although, other types of indications such as porosity or crack for example, shows actual defect and they are the relevant indications.

Non-Relevant Indication in Penetrant Testing

While penetrant testing is generally very reliable, it can occasionally produce non-relevant indications. A nonrelevant indication is an indication that does not correspond to any actual discontinuity in the material.

Nonrelevant indications can be caused by a variety of factors, including surface contamination, incorrect application of the penetrant, and flaws in the test equipment.

Fortunately, nonrelevant indications can often be identified and eliminated using simple techniques such as scanning with a magnifying glass or using a reference material.

Liquid Dye Penetrant Testing Acceptance Criteria for ASME Section V

ASME Section V Article-6 is applicable for Liquid Penetrant Testing / Examination. ASME Section-5 only provides LPT techniques and does not give any acceptance criteria.

For Penetrant Testing acceptance criteria user need to refer to the applicable construction code such as ASME Section VIII or ASME B31.3 or API 1104, for example.

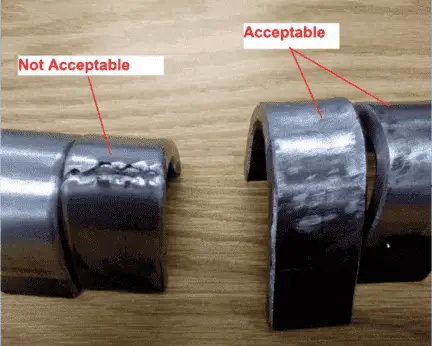

Liquid Dye Penetrant Testing Acceptance Criteria for AWS D1.1

AWS D1.1 offers acceptance criteria for LPT, which helps ensure that the method is being used effectively and produces reliable results.

The acceptance criteria set forth in AWS D1.1 are based on the principles of good practice and provide a framework for assessing the acceptability of LPT results.

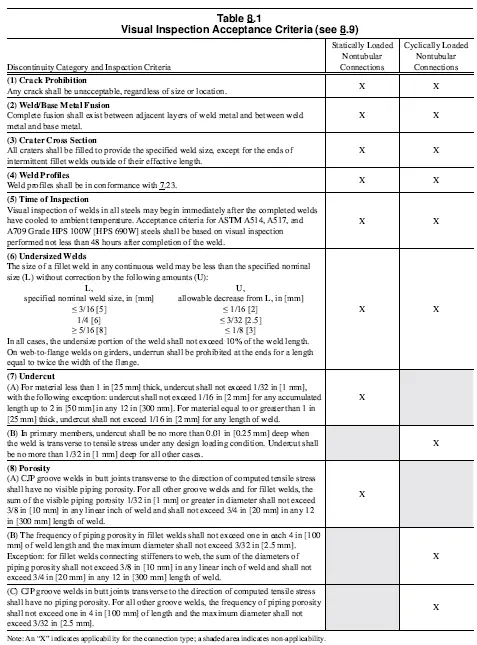

All Penetrant Testing indications shall be verified whether or not they are relevant indications. Once the relevancy of indication is established, the acceptance criteria provided in Table 8.1 for Visual Testing apply to Penetrant Testing evaluation also. Below is the abstract of AWS D1.1, Table 8.1 for reference.

Liquid Dye Penetrant Testing Acceptance Criteria for API 1104

The Liquid Dye Penetrant Testing Acceptance Criteria in API 1104, clause 9.5 applies for

- Linear Indications

- Rounded Indications

The acceptance is considered the basis of relevant indications (any LPT indications having a dimension more than 1/16 inches or 2 mm) only need to be evaluated.

API 1104 LPT acceptance for Linear Indications:

- Crater cracks or star cracks having lengths of more than 5/32 inches (4 mm) shall be rejected.

- Any linear indication having a length more than 1 inch (25 mm) in a total continuous length of 12 inches (300 mm) or 8% of weld length, shall be considered as Incomplete fusion (IF) & shall be rejected.

- Any crack other than a star Crack or Crater Crack shall be rejected.

API 1104 LPT acceptance for Rounded Indications:

For rounded indication acceptance criteria given in API 1104 Clause 9.3.9.2 & 9.3.9.3 applies. The size of a rounded indication is considered the basis of its maximum dimension.

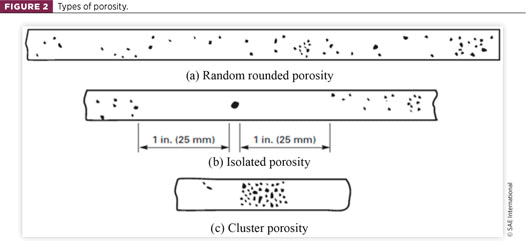

An example of rounded indication is Welding porosity (any type). For the acceptance of rounded indications, the following criteria apply:

- Any rounded indication having a size of more than 1/8 inches (3mm) shall be considered a relevant indication and shall be rejected.

- Scattered porosity that exceeds the concentration permitted in API 1104 figure 19 or 20.

- Cluster porosity (CP) having a diameter of more than 1/2 inch (13 mm) shall be rejected. Or, any cluster porosity or combined CP, having a length more than 1/2 inches (13 mm) in a total continuous length of 12 inches (300 mm) shall be rejected.

Liquid Dye Penetrant Testing Acceptance Criteria for ASME B31.1

Liquid Dye Penetrant Testing Acceptance Criteria is given in ASME B31.1. As per ASME B31.1, two types of indications are applied-

- Linear Indications, E.g Crack, lack of fusion.

- Rounded Indications, Eg., Porosity, Slag inclusion.

- Only relevant indications need to be evaluated. Relevant indications are one having a size (any dimension) more than 1/16 inches (1.5 mm).

- Linear indications mean the indication having a length more than 3 times of its width.

- Rounded indications (circular or elliptical shape) are one having a length equal to or less than 3 times of its width.

following acceptance criteria applies for Liquid Penetrant Test or Dye Penetrant Test:

- The examined area shall have no relevant linear indications.

- No rounded indications more than 3/16 inches (5 mm) is permitted.

- In case of combined linear or rounded indications, the examined surface shall be free from 4 or more relevant indications in a line separated by 1/16 inches (1.5 mm) or less.

Liquid Dye Penetrant Testing Acceptance Criteria for ASME B31.3

Liquid Dye Penetrant Testing Acceptance Criteria is given in ASME B31.3, Clause 341.3.2 which further references to clause 344.4.2 for LPT acceptance.

As per ASME B31.3, two types of indications are applied-

- Linear Indications, E.g., Crack, lack of fusion.

- Rounded Indications, Eg., Porosity, Slag inclusion.

- Only relevant indications need to be evaluated. Relevant indications are one having size (any dimension) more than 1/16 inches (1.5 mm).

- Linear indications means the indication having a length more than 3 times of its width.

- Rounded indications (circular or elliptical shape) are one having length equal to or less than 3 times of its width.

following acceptance criteria applies for Liquid Penetrant Test or Dye Penetrant Test:

- Examined area shall have no relevant linear indications.

- No rounded indications more than 3/16 inches (5 mm) is permitted.

- In case of combined linear or rounded indications, the examined surface shall be free from 4 or more relevant indications in a line separated by 1/16 inches (1.5 mm) or less.

Liquid Dye Penetrant Testing Acceptance Criteria for ASME Section VIII Div. 1

in ASME Section VIII Division 1, Liquid Dye Penetrant Testing Acceptance Criteria is given in Mandatory Appendix 8.

This appendix cover requirement for Liquid Penetrant Examination (PT) in Clause 8-4.

The following acceptance criteria applies for LPT:

- The examined area shall be free from any linear indications (Crack, LOF, LOP, etc.).

- Rounded indications more than 3/16 inches (5 mm ) shall be rejected.

- In case of combined linear or rounded indications, the examined surface shall be free from 4 or more relevant indications in a line separated by 1/16 inches (1.5 mm) or less.

Similar Posts: