Hardness control for Sour services

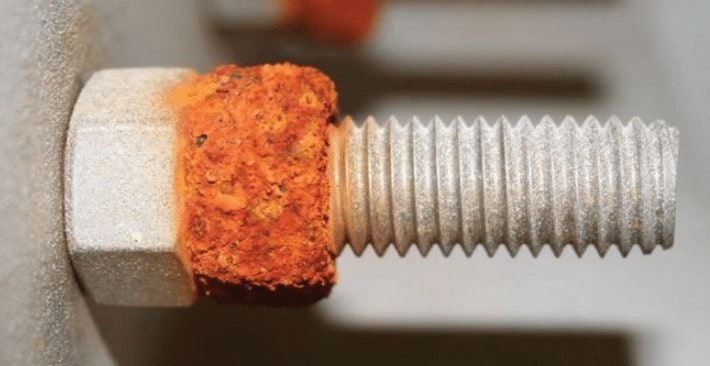

This article provides quick references for hardness test requirements in sour service applications of Carbon steel, and low alloy steel. Hardness control is one of the numerous methods used to prevent S-SCC (Sulphide stress corrosion cracking) in sour service and Hydrogen induced cracking in general.

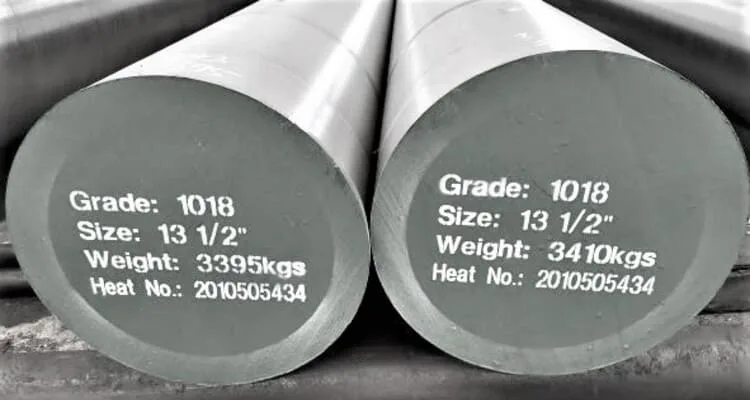

Metal susceptibility to S-SSC is closely related to material strength (as indicated by hardness), which is affected by chemical composition, heat treatment, fabrication method, and microstructure present in the material.

Standards for Hardness Testing & hardness requirements:

- ISO 6506-1, Brinell hardness test, Part 1: Test method

- ISO 6507-1, Vickers hardness test, Part 1: Test method

- ISO 6508-1, Rockwell hardness test, Part 1: Test method

- EFC 16, Guidelines on Materials Requirements for Carbon and Low Alloy Steels for H2S-Containing Environments in Oil and Gas Production

- NACE MR0175-2, Materials for Use in H2S Containing Environments in Oil and Gas Production, Part 2: Cracking Resistant Carbon and Low Alloy Steels, and the Use of Cast Irons

- NACE MR0103, Metallic Materials Resistant to Sulfide Stress Cracking in Corrosive Petroleum Refining Environments

- NACE SP0472, Methods and Controls to Prevent In-Service Environmental Cracking of Carbon Steel Weldments in Corrosive Petroleum Refining Environments

- NACE Publication 8X194, Materials and Fabrication Practices for New Pressure Vessels Used in Wet H2S Refinery Service

- ASTM E140, Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, and Scleroscope Hardness

- ISO 18625, Conversion of Hardness Values

Hardness Test

Rockwell (HR) hardness test has many scale options with different indenter types and sizes. For carbon steel in sour service, only HRC and HR 15 N are allowed to be used, both using diamond cone indenter.

HRC is a standard test used for testing bulk metal while HR 15 N is superficial for testing small and localized areas like HAZ. Rockwell is popular because of its quick and easy-to-get results. Vickers (HV) hardness test, sometimes called microhardness test only use one type of indenter of pyramid-shaped diamond with different load.

Depending on the standards used, HV 30, HV 10, & HV 5 are allowed for tests. HV 30 is used for bulk metal, HV 10 is for HAZ, and HV 5 is used for low arc energy welds (<2.5 kJ/mm) which may have a very tight HAZ area.

Since hardness needs to be measured visually by microscope (which can be manual or automated by software), detailed sample preparation is needed. But it is also advantageous because the test can be specific to certain microstructures in the metal and is very reliable to find hard spots in HAZ.

Brinell’s (HBW) hardness test apparatus is using a tungsten carbide ball indenter, normally using a 10 mm diameter and a force of 29.42 kN. Test measurements also need to be measured visually, but the main difference with Vickers is that impression size is significantly bigger, and minimal sample preparation is enough.

Brinell is good for measuring bulk material especially when different phases exist but shall not be used to measure HAZ.

Summary of Hardness Requirements

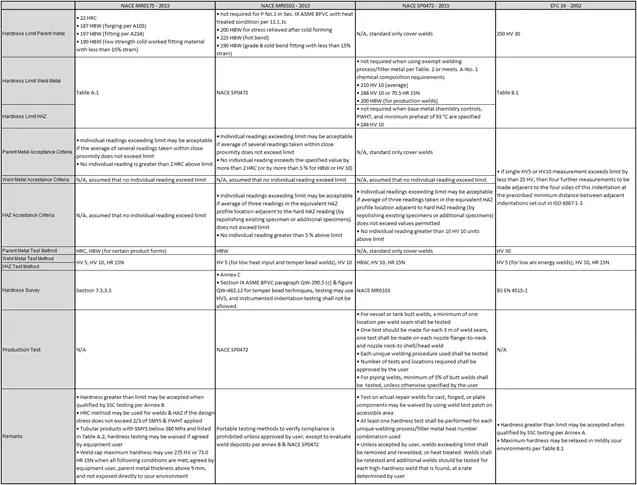

The below table summarizes the hardness requirements for weld, HAZ, and base metal requirements as per NACE MR0175, NACE MR0103, NACE SP0472, and EFC-16.

Click here to download this table in pdf with a higher resolution.

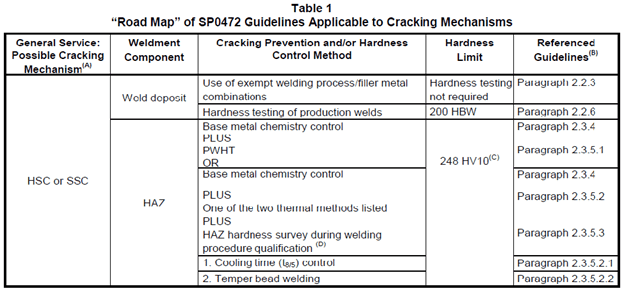

Hardness limit per NACE MR0175-2

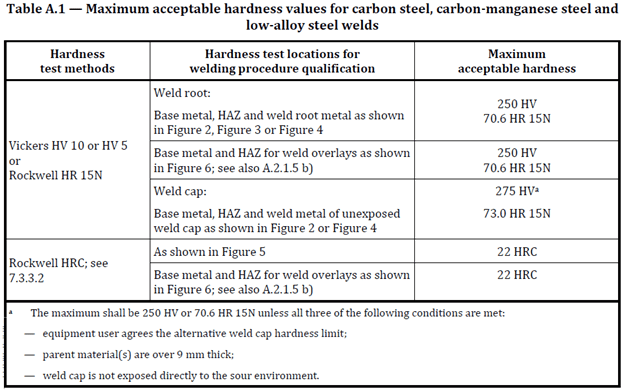

Hardness limit per EFC 16

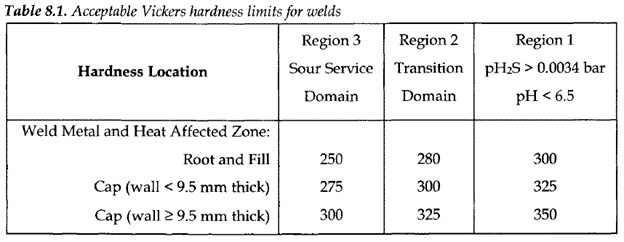

Hardness limit per NACE SP0472

General Hardness Control

A higher hardness limit in the weld & HAZ cap for the external surface reflects the less severe hydrogen concentration at the hydrogen exit side. If hydrogen exit from the external surface is impeded (ex: by cathodic protection) then the hardness of the cap shall not exceed the root limit.

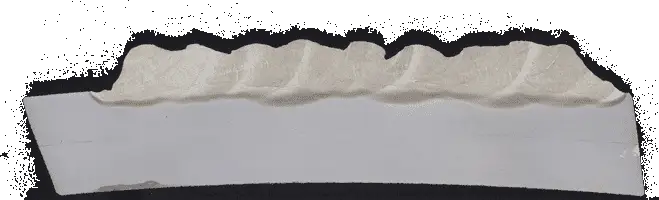

Concern for maximum hardness is that likely it will happen in HAZ or weld metal close to the fusion boundary with the highest possible value when using low arc energy or low t8/5 values like fillet welds.

In addition, these also give rise to narrow HAZ that may be difficult to sample accurately. Weld metal or HAZ which experiences little or no reheating by subsequent passes. In general, will be the hardest. When using parent metal with high carbon, concern for migration to weld metal, giving peak hardness just within the weld.

Regions of high hardness are often identified as areas that etch heavily in a standard Nital etch. Nevertheless, light etching regions should also be examined, as hard martensitic regions may be resistant to etching.

Typically, a reliable way to assess weld area hardness is by using a small impression. HAZ hardness impressions shall be entirely within HAZ and located as close as possible to the fusion boundary between the weld metal and HAZ.

Weld cap HAZ survey should be positioned so that impressions coincide with the HAZ of the final run or change of profile of the fusion line associated with the final run.

Hardness Conversion Accuracy (HRC or HV?)

There is a slight hardness conversion difference between standards for 22 HRC although not very significant, some use 250 HV and 248 HV. This is normal, as explained in ASTM E140, hardness scale conversion is only an approximate process, and not possible to state confidence limits for the errors in using a conversion chart.

Hardness difference is also affected by parameters like composition, properties, heat treatment, etc that may be slightly different even for similar materials. The conversion tables were also performed in the past using ASTM test methods in effect at the time of testing, updated standards may affect final results.

For example, currently, both the Rockwell and Brinell hardness standards allow or require the use of tungsten carbide ball indenters; however, all of the ball scale Rockwell hardness tests and most of the Brinell hardness tests performed to develop these tables used hardened steel ball indenters.

Some fixed-location and portable hardness testers perform internal conversions between hardness scales using the tables in ASTM E140 or ISO 18265. There may also be some instances where hardness scale conversions are handled outside of the standards based on proprietary data or algorithms, especially in some portable instruments where no standardized conversion tables exist.

In either case, conversions may be an additional source of inaccuracy and uncertainty.

By: Andry Soetiawan

Material & Corrosion Engineer– Article shared by the author & also available on his Linkedin post (Below Link).

Guidelines for Carbon Steel Hardness Test for Sour Service | LinkedIn

Thank you well explained.