What is Hydrogen induced cracking (HIC)

The most serious problem of weldability in carbon and low-alloy steels is hydrogen induced cracking in the heat-affected zone of the base metal.

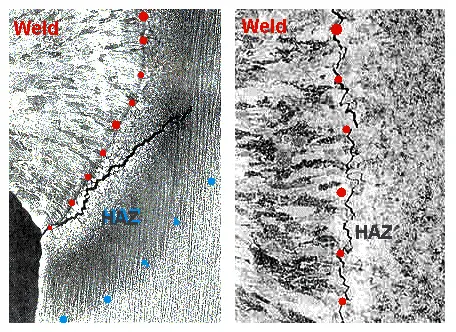

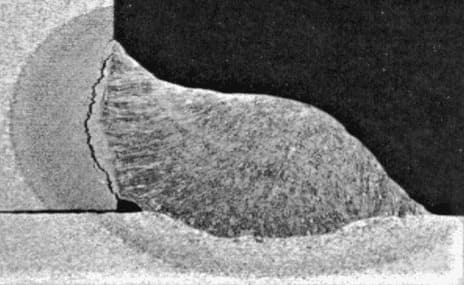

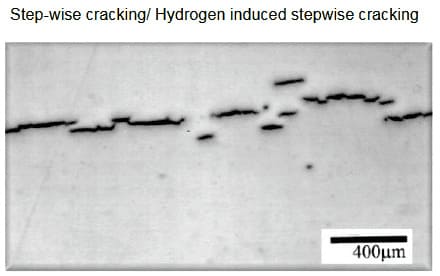

HIC cracking often occurs after the welding has been completed and the weldment has cooled down. It lies underneath the weld bead and is not easily detected.

Many service failures due to fatigue and brittle fracture have been traced to pre-existing cracks in the HAZ. Such cracks have led to the fracture of pressure vessels during hydraulic testing and collapse of bridges and storage tanks in service.

Hydrogen-induced cracking (HIC) is also known as:

- Cold cracking, because it occurs when the metal has cooled below 150°C

- Delayed cracking, because its formation is sometimes delayed for 20 hours or more,

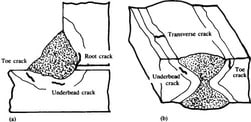

- Underbead cracking, because in most cases it is located at the HAZ underneath the weld bead.

- Hydrogen Embrittlement

- Hydrogen Blistering

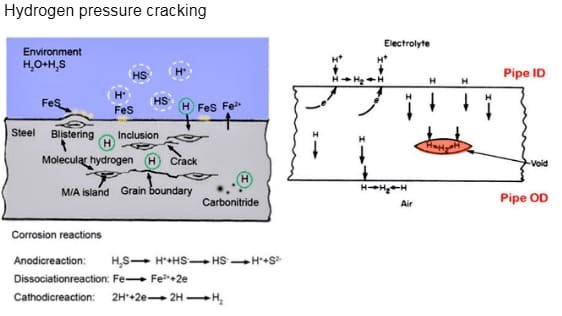

HIC Cracking occurrence Phenomena

HIC occurs in the HAZ when:

a) Sufficient hydrogen is present in the welding arc. Hydrogen is derived from organic materials and minerals having chemically combined water used in the covering of manual electrodes or flux in SAW or flux cored wires.

The main source, however, is moisture which is inevitably present in all types of fluxes. Oil, grease, paint and moisture on the base metal surface or electrode-wire surface can also generate hydrogen during welding.

b) Shrinkage stresses, supplemented by other stresses developed as a result of joint restraint, acting on the weld.

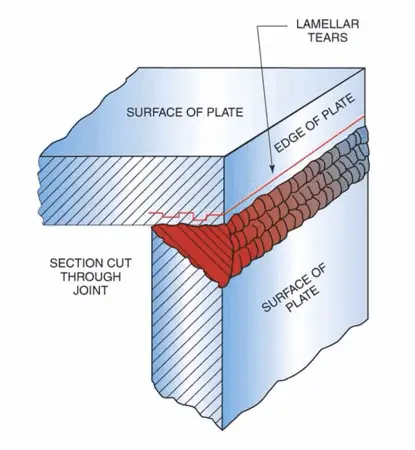

c) A sufficiently hard and brittle microstructure develops in the HAZ as a result of its being heated to above A, temperature and cooled rapidly. The usual sites of HAZ cracking in butt and fillet welds are usually under the bead, hence it is called underbead cracking.

Cracks can also occur in welds if their alloy content is high and the conditions leading to HAZ cracking as enumerated above are present. They appear to be transgranular under the microscope.

Factors causing HIC Cracking

Hydrogen induced cracking is caused when below conditions presents:

- Hard microstructure: E.g., Martensite

- Residual stresses

- Molecular Hydrogen

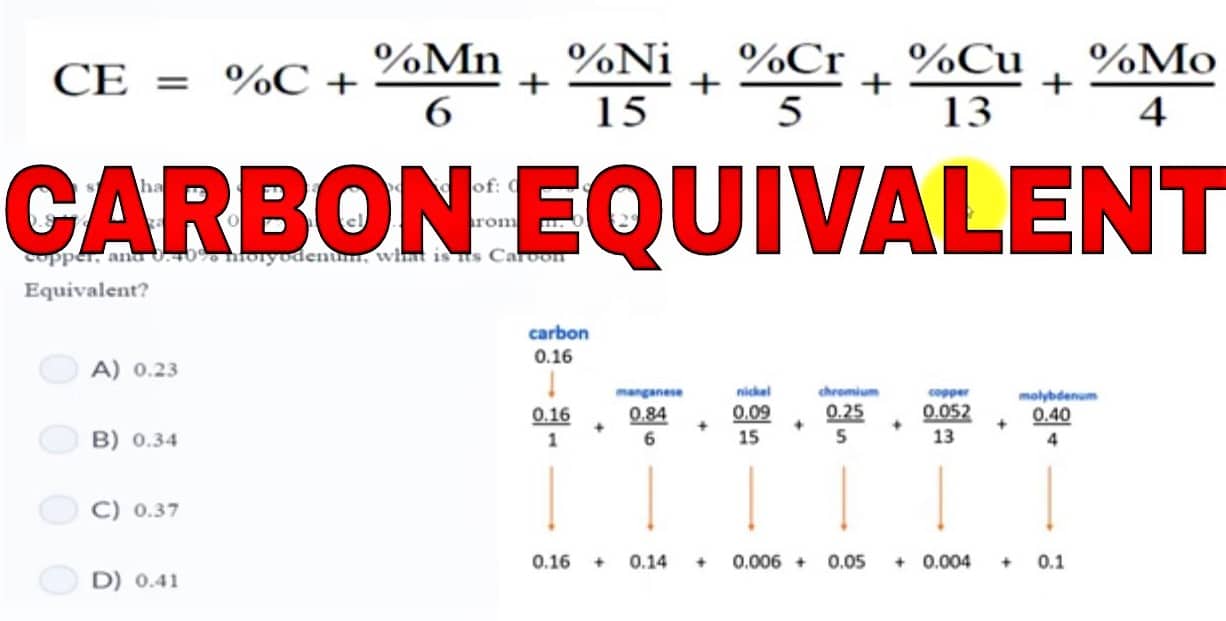

Taking steel of a particular composition and thickness, heat input rate coupled with preheat, if necessary, should be so chosen as to avoid the formation of martensite in the HAZ.

Martensite is not acceptable, because it is brittle. In addition, in the presence of hydrogen and restraint-induced stresses it can cause delayed cold cracking in the HAZ.

Hydrogen is generated in the welding arc by the dissociation of moisture present in the electrode coating or submerged-arc flux, or by the combustion of organic compounds which are sometimes present in the electrode coatings of the rutile and cellulosic types.

Hydrogen is also generated from the oil and grease, which may exist on the plate edges or on the bare welding wire.

How to control HIC Cracking?

Hydrogen-induced cracking can be controlled by,

- (1) using hydrogen-controlled electrodes and dry, clean submerged-arc welding consumables,

- (2) by control of joint design, and

- (3) by delayed cooling of the HAZ after transformation to allow hydrogen to diffuse out.

Remember that removal of hydrogen above the transformation temperature is not possible, because the diffusion rate of hydrogen in austenite is too low.

The phenomenon of hydrogen- induced cracking and methods of preventing its occurrence will be explained at length in Chapter 10, page 516.

Sometimes one has to weld hardenable steels under restraint, where martensite formation and cold cracking are likely to occur even after using best welding procedures and hydrogen- controlled electrodes.

In such cases, the remedy lies in ensuring delayed cooling of the HAZ by extending preheating into post heating without interruption.

Postheat temperature of 200°C maintained for several hours (up to a maximum of ten hours) will drive off all hydrogen, while raising this temperature to 600° C to stress-relieve the fabrication will remove all hydrogen within an hour or so.

The stress-relief must be insisted upon where brittle (though uncracked) martensite in the HAZ may endanger the safety of the structure in service.

Hydrogen Induced Cracking Test

Hydrogen Induced Cracking Test is given in NACE TM0284. This standard covers the complete requirements for the HIC test including sample preparation, sample size, test duration and test conditions.

Read more:

- Defects / Hydrogen Cracks in Steels – Identification

- What Is Hydrogen Cracking Or Delayed Cracking Or Cold Cracking?

- What is Hydrogen Induced Cracking (HIC)?