HY-100, HY-100(T) and HY-130 steels

HY-100, HY-100(T) and HY-130 steels developed in the U.S.A. have been described as ‘premium-toughness high-yield strength steels of the quenched and tempered type’.

Like HY-80 steel, HY-100 is used in the construction of military, marine and commercial hydrospace vehicles.

HY-130 has been specially developed for use in the more demanding hydrospace and aerospace applications.

HY 100, HY130 Steel Material Specification

The UNS Number of HY100 steel is UNS K32045. The main material specification for HY100 and HY130 alloys are:

- MIL-S-24371

- T9074-BD-GIB-010/0300

- MIL-S-21952

HY100 Steel Chemical Composition and Mechanical Properties

HY-100 is a 100 ksi (690 N/mm²) yield steel based on HY 80 composition, but with higher Ni and Cr contents. It is specified in ASTM A543 class 2.

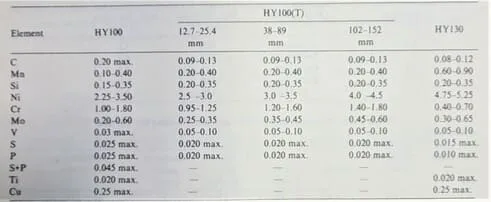

HY100 Steel Chemical Composition is given in the below table.

| Element | Content (%) |

|---|---|

| Fe% | 92.8 to 96.2 |

| Ni% | 2.25 to 3.50 |

| Cr% | 1.0 to 1.80 |

| Cu% | 0.25 max. |

| Mo% | 0.20 to 0.60 |

| Si% | 0.15 to 0.35 |

| C% | 0.12 to 0.20 |

| Mn% | 0.10 to 0.40 |

| V% | 0.030 max. |

| P% | 0.025 max. |

| S% | 0.025 max. |

| Ti% | 0.020 max. |

HY130 Steel

HY 130 is a steel with a yield strength in the range of 130-150 ksi (895-1030 N/mm²) and is based on 5% Ni with additional Cr, Mo and V.

A modified version of HY-100, designated by the U.S. Navy as HY-100 (T) is based on HY-130 and has better weldability.

It is an electric furnace vacuum-degassed 3% Ni-Cr-Mo-V steel, which exhibits better fracture toughness properties.

Chemical compositions of HY100, HY100T and HY130 steels are given in Table below.

Welding HY100 Steel

Electrodes of over-matching strength conforming to AWS E12018-M (military grade low alloy welding rod as per AWS A.5 specification) are used for welding HY-100 steel.

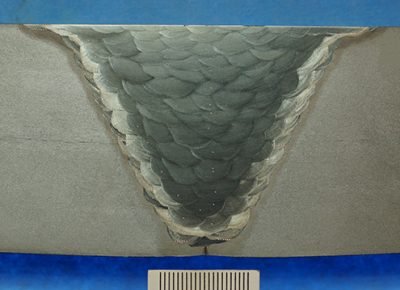

HY-80 welding procedures are used, but the risk of HAZ and weld-metal cracking due to hydrogen is more pronounced, because of higher carbon equivalent and higher strength of weld-metal.

In the case of HY-100(T) steel, the risk of cold cracking is much less than in the case of HY-80 steel, because of lower CE (0.85 maximum for the maximum composition as compared to 0.95 for HY-80). HY-100(T) is also welded by the MIG process.

Welding HY130 Steel

For welding HY-130, special E14018 class electrodes have been developed in the U.S.A. For MIG welding, a special Mn-Ni-Cr-Mo wire is used with argon-2 to 5% oxygen mixture as a welding shielding gas.

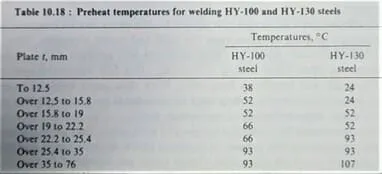

Welding Preheat and Interpass Temperature for HY100, HY130 Steels

Hydrogen-induced cracking in the HAZ is not a serious problem in the case of HY-130 steel, but weld-metal cold cracking is a significant problem.

To avoid it, the interpass temperature during welding with E14018 electrodes should be 135° C minimum and one hour should elapse between the deposition of adjoining beads within a layer or the beads in one layer to the next.

The interpass temperature should be prolonged for at least one hour as a postweld heat treatment.

Minimum preheat and interpass temperatures for welding various thicknesses of HY-100 and HY-130 steels are given in Table below.

In one particular HY-130 fabrication control the welding heat input limits and carry out welding in the flat position using stringer bead technique. This will give a number of welding passes which will refine the subsequent weld passes by tempering.