ASTM A514 Material

ASTM A514 is a Quenched and Tempered (Q & T), high strength Steel Plate material having good weldability properties for use in welded bridges and other structures.

But ASTM A 517 is a Pressure Vessel Plate of Alloy Steel with High-Strength in Quenched and Tempered conditions. ASTM A514 being a high-strength material is prone to delayed cracking.

In fabrication due to this reason, NDT (visual inspection or UT or RT- for example) is usually performed after 48 hours of weld completion, this time is called inspection hold time to ensure there is no cold cracking in the weldments.

They have higher corrosion resistance compared to usual carbon steel materials and are used also without painting.

In this article, I have covered detailed welding guidelines for welding ASTM A514T-1 and other grades from welding engineer prospective.

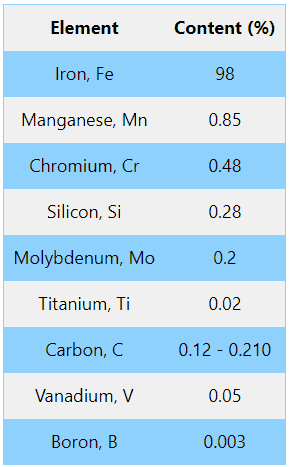

Chemical properties of ASTM A514, SA 517

The chemical composition of ASTM A514 Grade B, S, and E are different. The carbon percentage in A514 is 0.12% to 0.21%. every grade of ASTM A514 has different chemical composition requirements, below chemistry requirements for ASTM A514 Grade B are given.

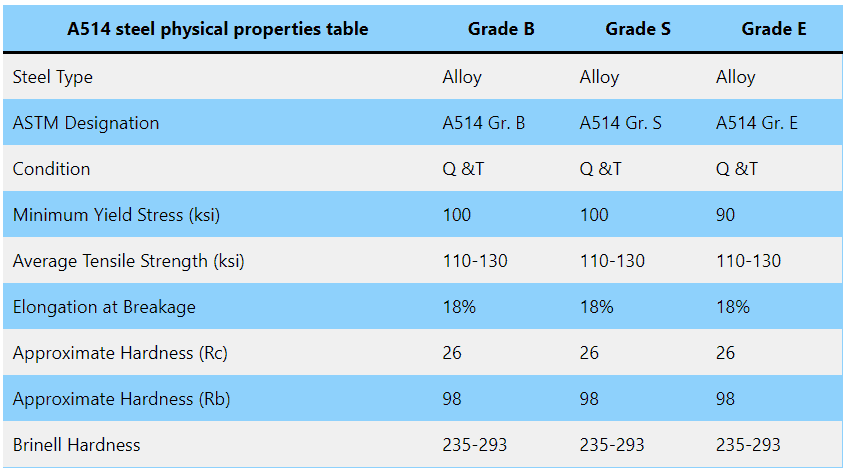

Mechanical properties of ASTM A514

Welding T-1 Steel

The ASME Section IX Welding P-Number of ASTM A514 T-1 steel is P Number 11B. THE P Number for ASTM A517 is also 11B.

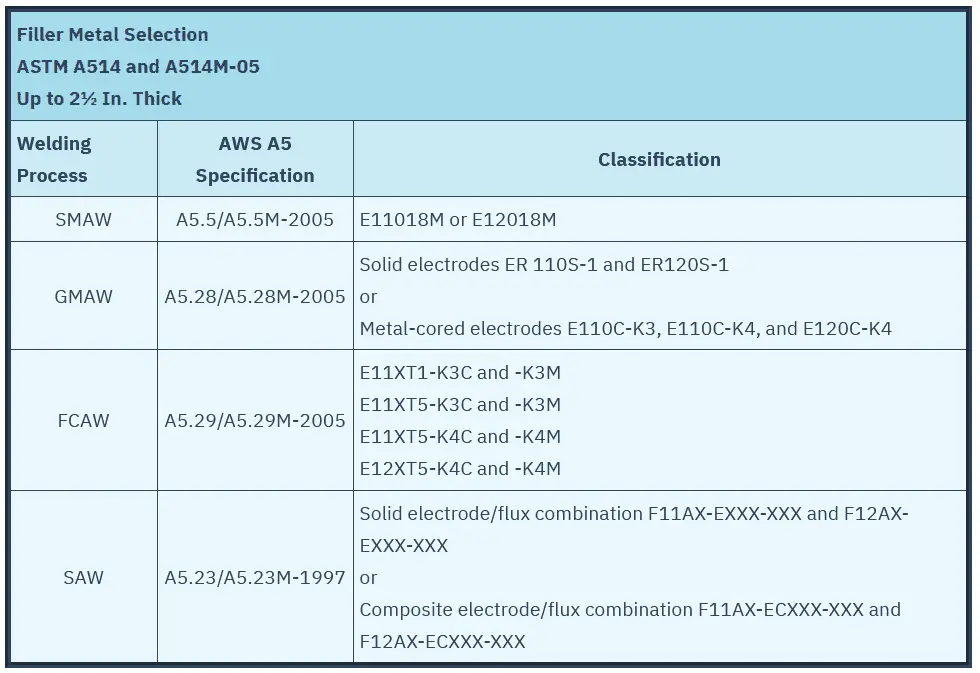

Welding electrode/ TIG MIG filler for ASTM A514, A517

Stick (SMAW) welding of ASTM A514, A517 T-1 materials shall be carried out using E11018 which offers high tensile strength and matching weldment properties. All stick welding electrodes must be baked (dried) at a temperature of 700°F to 800°F (370°C and 430°C) before use.

👉👉Get Audel Welding Pocket Reference Book👉👉

TIG/ MIG welding shall be carried out using ER110S-1. Make sure the filler wire with G classification meets the minimum mechanical properties requirements for the base metal. Use Argon-CO2 mixture for the shielding in GMAW. Pure argon shall be used in TIG welding. A detailed summary is given in the below table.

AWS D1.1 Table 6.9 also give welding consumable/ rod recommendation for welding ASTM A514 materials using E l0015-X, E l0016-X, E l0010-X, E l0018-M type stick welding rod as per AWS A5.5 specification.

AISI 8620 (21NiCrMo2) welding procedure & guidelines

FCAW welding of ASTM A514, A517 shall be carried out with E110T5-k4, Shielding shall be made with an Argon-CO2 gas mixture.

Welding concerns with ASTM A514, A517

- Risk of Hydrogen cracking/Delayed Cracking

- Selection of right welding preheat temperature

- High residual stresses.

Welding Recommendations

- With SMAW, use only low hydrogen electrodes that give weld metal of required strength and toughness. The electrode must be baked before welding except for hermetically sealed low hydrogen electrodes.

- For SAW or submerged arc welding, weld using hydrogen-controlled electrodes and fluxes that give weld metal of required strength and toughness.

- For GMAW & FCAW, weld with low hydrogen type welding rods for good mechanical properties.

- Welding with stringer bead method and restrict the weaving to max two time of rod dia. if required. Any welding gouging with carbon electrode shall be grinded to ensure no carbon deposit in the weld area.

- Smoothly grind the weld profiles to reduce stress concentration points.

- Apply peening to reduce cracking due to high residual stresses.

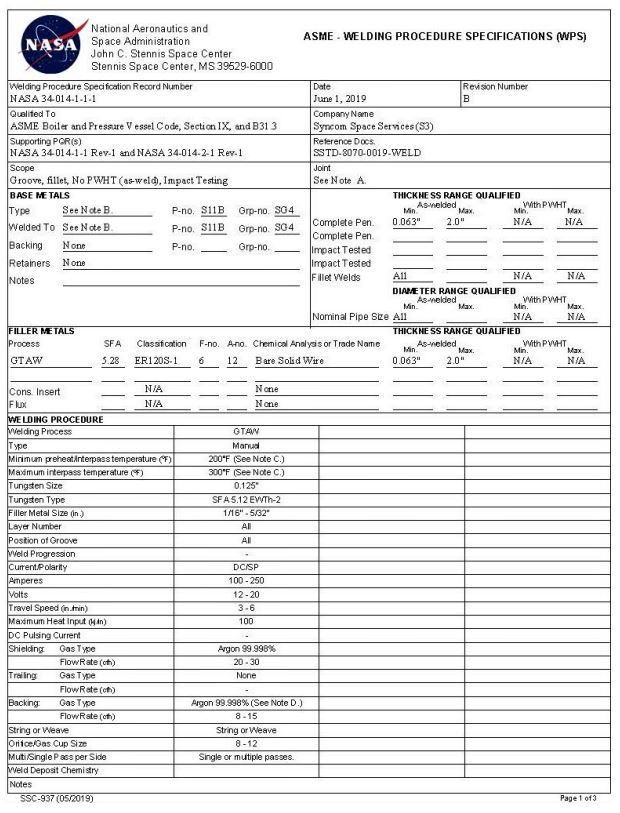

Below is NASA welding procedure for A514 steel.

Preheat/Interpass & PWHT of ASTM A514, A517

Selection of the right preheats temperature is very critical in ASTM A514, A517 material to avoid any hydrogen cracking.

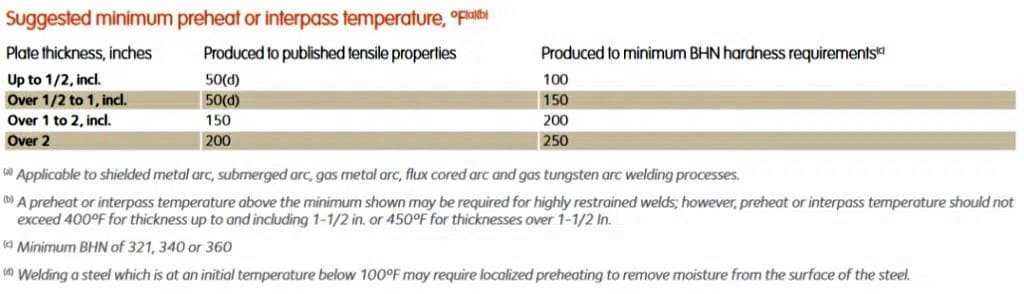

The maximum welding preheat and interpass temperature shall not cross 400°F or 200°C for material up to 1-.5 inches or 38 mm, and 450°F or 230°C for more than 1.5 inches according to the limitation given in AWS D1.1 code.

PWHT of ASTM A514 is not recommended is generally not carried out as it will degrade the mechanical properties of the ASTM A514 material.

PWHT will reduce the material toughness and intergranular corrosion cracking can occur in the heat-affected zone or HAZ. PWHT of ASTM A514 materials will reduce the material ductility and can cause HAZ cracking also.

The steel manufacturer typically provides recommendations for the appropriate preheating temperature. This recommendation can vary by 25-50 ºF depending on the steel grade. Preheating temperatures, based on plate thickness, are commonly suggested as follows:

- Up to ½”: 50-100 ºF

- Over ½” to 1″: 50-150 ºF

- Over 1″ to 2″: 150-200 ºF

- Over 2″: 200-250 ºF

It’s important to note that highly constrained joints may require higher preheating temperatures. Additionally, the preheating temperature should not exceed 400 ºF for thicknesses up to 1-1/2″ or 450 ºF for thicknesses over 1-1/2″. In the case of quenched and tempered (Q&T) steel, both maximum preheating and interpass temperatures must be adhered to, not just minimums.

During preheating, it is crucial to measure the temperature 3 inches away from the joint in all directions along the joint. If the plate thickness exceeds 3 inches, the distance from the joint where the temperature is measured should be equal to or greater than the plate’s thickness.

You can find more useful information on welding A514/A514M-05 steel in the following codes:

- AWS D1.1 structural welding code

- AWS D14.3 Code

- AWS D15.1 Code

Welding A514/T1 plate to 4140

Welding A514/T1 (also known as T-1) steel plate to 4140 steel requires careful consideration due to their different chemical compositions and mechanical properties. Here are a few points to consider:

- Preheat and Interpass Temperature: Both A514/T1 and 4140 steels have high hardenability, so preheating and maintaining interpass temperatures are crucial to prevent cracking and ensure weld integrity.

- Welding Process: The welding process used should be compatible with both A514/T1 and 4140 steels. Common welding processes include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and submerged arc welding (SAW).

- Filler Metal Selection: The choice of filler metal is critical when welding dissimilar steels. It is recommended to use a filler metal that matches the higher strength of the two materials or a filler metal specifically designed for welding high-strength steels or you can use ER70S-2.

What is the difference between ASTM A572 and A514?

ASTM A572 and A514 are both high-strength, low-alloy (HSLA) steels, but they have distinct differences in terms of their chemical composition and intended applications.

ASTM A572:

- A572 is a standard specification for high-strength, low-alloy columbium-vanadium structural steel.

- It is primarily used in structural applications such as buildings, bridges, and construction equipment.

- A572 steel grades have different yield and tensile strength levels, including grades 42, 50, 55, 60, and 65.

- The composition of A572 steel includes elements such as columbium, vanadium, manganese, and silicon to enhance its mechanical properties.

ASTM A514:

- A514 is a standard specification for high-yield strength, quenched and tempered alloy steel plate.

- It is mainly used for welded bridges and structures where weight reduction or durability is critical.

- A514 steel grades have different yield strength levels, including grades B, H, F, Q, and S.

- The composition of A514 steel includes elements such as carbon, manganese, phosphorus, sulfur, silicon, copper, chromium, nickel, molybdenum, boron, vanadium, and titanium, which contribute to its high strength and toughness properties.

| Element | ASTM A572 Grade 50 | ASTM A514 Grade B |

|---|---|---|

| Carbon (C) | 0.23% max | 0.12-0.21% |

| Manganese (Mn) | 1.35% max | 0.45-0.70% |

| Phosphorus (P) | 0.040% max | 0.035% max |

| Sulfur (S) | 0.050% max | 0.035% max |

| Silicon (Si) | 0.15-0.40% | 0.20-0.35% |

| Copper (Cu) | 0.20% min (when specified) | 0.20% min (when specified) |

| Nickel (Ni) | 0.50% max (when specified) | 0.50% max (when specified) |

| Chromium (Cr) | 0.30% max (when specified) | 0.30-0.70% |

| Molybdenum (Mo) | 0.10% max (when specified) | 0.20-0.35% |

| Boron (B) | – | 0.001-0.005% |

| Vanadium (V) | – | 0.03-0.08% |

| Titanium (Ti) | – | 0.01-0.02% |

What is the difference between A36 and A514?

A36 and A514 are both steel grades used in different applications and have distinct differences in terms of their mechanical properties, chemical composition, and intended uses.

ASTM A36:

- A36 is a standard specification for carbon structural steel, commonly used in construction and structural applications.

- It has a minimum yield strength of 36,000 psi (250 MPa) and ultimate tensile strength of 58,000-80,000 psi (400-550 MPa).

- A36 steel is known for its low carbon content, making it relatively easy to weld and form.

- It is typically used for general structural purposes, such as beams, columns, and bridges.

ASTM A514:

- A514 is a standard specification for high-yield strength, quenched and tempered alloy steel plate.

- It is primarily used for welded bridges and structures where weight reduction or durability is critical.

- A514 steel grades have different yield strength levels, ranging from 100 to 690 MPa (14,500 to 100,000 psi), depending on the grade.

- The chemical composition of A514 steel includes elements such as carbon, manganese, phosphorus, sulfur, silicon, copper, chromium, nickel, molybdenum, boron, vanadium, and titanium, which contribute to its high strength and toughness properties.

- A514 steel requires careful consideration of preheat and interpass temperatures during welding due to its high yield strength and quenching and tempering process.

| Element | ASTM A36 | ASTM A514 Grade B |

|---|---|---|

| Carbon (C) | 0.25% max | 0.12-0.21% |

| Manganese (Mn) | 0.80-1.20% | 0.45-0.70% |

| Phosphorus (P) | 0.04% max | 0.035% max |

| Sulfur (S) | 0.05% max | 0.035% max |

| Silicon (Si) | – | 0.20-0.35% |

| Copper (Cu) | – | 0.20% min (when specified) |

| Nickel (Ni) | – | 0.50% max (when specified) |

| Chromium (Cr) | – | 0.30-0.70% |

| Molybdenum (Mo) | – | 0.20-0.35% |

Can we Weld ASTM A514 Steel? is it weldable?

Which rod rod is best for welding A514 Steel?

Thanks mate, Which rod you recommend for welding A514 to A36 material?