What is Corten Steel?

Welding Corten Steel requires right preparation, correct welding electrodes and knowledge about material & it is covered in depth in this post. Corten Steel is a weathering steel. When it s exposed to weather, it makes a rusty surface appearance that protects it from adverse weather conditions & corrosion. Corten steel properties include high strength, toughness and ductility.

The alloy is also resistant to atmospheric corrosion, making it a popular choice for outdoor architectural features and sculptures. It is made of an alloy that contains copper, manganese, and nickel. The steel is manufactured by adding a layer of corrosion resistant material to the surface of the steel. This layer protects the steel from rusting and weathering.

The properties of Corten Steel make it ideal for use in outdoor applications. The steel does not corrode or rust, even in harsh environments. It also has a high resistance to fatigue and abrasion.

Corten Steel is often used in architecture and landscape design. The steel can be used to create fences, gates, bridges and other structures. It can also be used to create sculptures and other decorative pieces.

Corten Steel vs Stainless Steel

When it comes to choosing between Corten steel and stainless steel, there are a few key factors that you need to consider. Corten steel is known for its unique rust-like appearance, which can add visual interest to your project.

However, it is important to note that Corten steel is not as durable as stainless steel and may not be the best choice for applications that require a lot of wear and tear.

Stainless steel is a more versatile option, since it does not corrode or rust in most environments. It is also easier to maintain than Corten steel. Ultimately, the choice between Corten steel and stainless steel depends on your specific needs and preferences.

Corten Steel vs Mild Steel

Corten Steel and Mild Steel are two steel types commonly used in construction. Corten steel is a type of weathering steel that is made to resist rusting. Mild steel is a type of non-weathering steel that is not as resistant to rusting as Corten steel.

The main difference between Corten steel and mild steel is the level of corrosion resistance. Mild steel corrodes easily, while Corten steel has a higher level of corrosion resistance because of the way it is made.

This makes Corten steel a better choice for applications where exposure to the elements is likely, such as outdoor sculptures or building facades. Mild steel is less expensive than Corten steel, so it is often used for structural purposes where cost is a concern. Corten steel can also be used for structural purposes, but it costs more than mild steel.

Corten Steel Grades

CORTEN is a Trademark of US Steel. CORTEN Means:

- CO: Corrosion

- R: Resistance

- TEN: Tensile Strength

The common Corten Steel Grades are: ASTM A242, ASTM A606, ASTM A588 & ASTM A847.

Corten Steel Chemical Composition & Mechanical Properties

Corten steel is a type of weathering steel that is made from a blend of copper, chromium, and nickel & other important elements as listed in the table for ASTM A606 type Corten Grades. Other Notable Grades for this type of steel are- ASTM A242, ASTM A606, ASTM A588 & ASTM A847.

It has a chemical composition that allows it to create a protective layer on its surface that prevents corrosion. The layer also causes the metal to change color over time, which gives Corten steel its distinctive appearance. You can refer to the chemical & mechanical properties of ASTM A606, and ASTM A588 in the below table:

In addition to its aesthetic appeal, corten steel also has excellent mechanical properties, making it a popular choice for outdoor structures. The Tensile Strength of ASTM A Type 4 Grade is minimum 70 Ksi & Yield strength is 50 Ksi minimum.

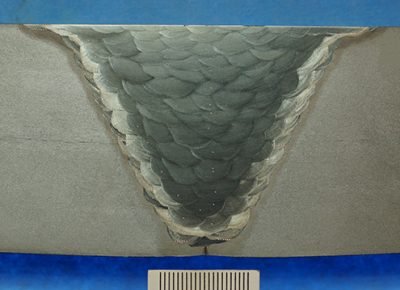

Corten Steel Welding

Welding Corten steel can be a bit tricky, but with the right preparation, it can be done without any problems. The first step is to preheat the metal when dealing with thick plates. This will help to prevent any warping or cracking during the welding process.

Once the metal is hot, you can start welding. Make sure to use a gas lens cup to help protect the weld from the wind when using TIG welding.

Welding Preheat & Interpass Temperature for Corten Weathering Steel

Preheat and Interpass temperature are important factors to consider when welding Corten steel. The preheat temperature should be between 150-225 degrees Fahrenheit, and the interpass temperature should be between a maximum of 400 degrees Fahrenheit. Below are the preheat requirements based on AWS D1.1 Code:

- For plate thickness up to 3/4 inches, no preheat is required.

- For thickness above 3/4 inches, preheat to 100-150 degrees Fahrenheit minimum.

- For thickness above 2.5 inches, preheat to 225 degrees Fahrenheit minimum.

Corten Weathering Steel Welding Electrode/Rods & Welding Wires

Corten Steel can be welded using the normal Stick (SMAW) Welding Electrode/ Rod or TIG-MIG Filler wires. Below are the suggested consumables for Welding of Corten Steel using Stick Welding, TIG Welding, MIG Welding & FCAW Welding.

These welding Rods & Welding fillers Wire are applicable for welding of ASTM A242, ASTM A606, ASTM A588 & ASTM A847 material grades.

- Corten Steel Welding using Stick Welding (SMAW) rod: E7018, E7018-W1, E8018-W2.

- Corten Steel Welding using TIG-MIG welding Filler Wire: ER70S-2, ER70S-6, ER80S-Ni1.

- Corten Steel Welding using FCAW: E71-T1C, E81T1-Ni1C, E 80T-W.

Corten Weathering Steel Stick Welding (SMAW)

Corten steel is a weathering steel that forms a stable rust-like patina when exposed to the elements. It is often used in outdoor sculptures and architecture. Corten steel can be welded using the SMAW (stick) welding process.

The most common electrode for welding Corten steel is E7018. This electrode produces a medium- to deep-penetrating weld with good mechanical properties. It can be used in all positions, but is most commonly used in the flat and horizontal positions.

E7018-W1 & E7018-W2 are specifically designed welding electrodes for Corten steel. It has a higher weld deposit than E7018, which results in increased corrosion resistance. It can also be used in all positions but is most commonly used in the flat and horizontal positions.

Welding Corten Steel to Mild Steel

Welding Corten steel to mild steel can be carried out easily without any issues. Use E7018 or E7018-W1, E8018-W2 type stick welding rod for welding Corten Steel to Mild Steel. TIG or MIG welding can be carried out ER70S-2, ER70S-6, ER80S-Ni1.

Welding Corten Steel to Stainless Steel

Welding Corten Steel to Stainless Steel is a process that joins two different types of steel together. Corten steel is weather-resistant steel that will form a rust-like appearance on the surface when exposed to the elements. Stainless steel is a type of steel that does not corrode and is used in many food and medical applications.

When welding these two types of steel together, it is important to use a filler metal that has the same corrosion resistance as stainless steel. A filler metal with a lower corrosion resistance could cause the Corten steel to corrode and fail prematurely.

In order to weld Corten steel to mild steel properly, use E309L Stick Welding Rod or ER309L TIG-MIG Filler Wire. Preheat is required for Corten Steel material only if the material is having a high thickness. Weld using low heat input, thus avoiding a high weld dilution of stainless steel material.

The weld should be cleaned of all contaminants before welding takes place. This can be done by using a wire brush or grinder to remove any paint, grease, or dirt from the surfaces that will be welded.

TIG-MIG Welding Corten Steel

Welding Corten steel can be tricky, but with the right techniques, it can be a great way to add strength and weather resistance to your project. Tig welding is a great option for Corten, as it produces clean, strong welds. Here are a few tips for Tig welding Corten steel:

- Make sure your base material is clean and free of rust or scale.

- Preheat the material if possible, to help avoid cracking during welding.

- Use a filler metal that has a similar composition to the base metal.

- Keep your welds cool and slow, to avoid overheating the steel and causing cracking.

What do you weld A588 Steel With?

Welding A588 steel is a process that requires a welder to have the correct welding rods and electrodes for the job. A588 steel is a type of alloy steel that is composed of carbon, manganese, silicon, phosphorous, and sulfur. The welding rods and electrodes used to weld this type of steel should be equipped with a high manganese content.

Can you weld Corten steel with 7018?

Welding Corten steel is a little different than welding other types of steel. It’s important to use the right type of welding wire and set the machine up correctly to get the best results. Some welders choose to use 7018 welding wire when they’re welding Corten steel.

This is a good choice for most applications, but it’s always a good idea to do some testing before you start welding on a critical project.

Is corten steel mild steel?

Corten steel is a weathering steel. Mild steel is not weathering steel. Corten steel has a higher resistance to atmospheric corrosion than mild steel.

Corten Steel Strength and Weakness

Corten steel is a type of weathering steel that is well-known for its durability and strength. It is often used in outdoor applications where it will be exposed to the elements. However, while corten steel is strong and durable, it does have some weaknesses. One such weakness is its susceptibility to rusting.

If not properly maintained, corten steel can rust quite easily, which can lead to corrosion and damage. Another weakness of corten steel is its tendency to deform over time. The metal can stretch and sag if it is not adequately supported. While these weaknesses should be considered when choosing corten steel for a project, they should not deter you from using this durable and beautiful material.

With proper maintenance and installation, corten steel can provide many years of lasting beauty and functionality. Corten steel is a weather resistant steel created by alloying copper, chromium and nickel. It is the main component of weathering steel.

Weathering steel, such as COR-TEN®, is a group of steels that were developed to obviate the need for painting, and form a stable rust-like appearance if exposed to the weather for long periods. COR-TEN® resists the corrosive effects of rain, snow, ice, fog and other meteorological conditions by forming a stable rust-like appearance on the surface of the metal.

The red oxide film that forms is self-repairing and prevents further corrosion from taking place. This type of steel is widely used in outdoor sculptures and architectural features because of its unique look.