How to Weld Galvanized Steel

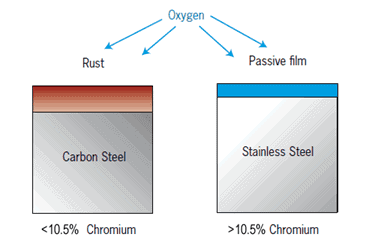

Galvanized steel is a type of steel that has been treated with a zinc coating to prevent rust and corrosion.

Knowing How to Weld galvanized steel is very important and complicated than welding regular steel because the zinc coating can produce toxic fumes when it is heated.

What is Galvanizing steel?

Galvanizing is the application of a zinc coating to ferrous metal surfaces to protect them from corrosion. It is an effective means for retarding the corrosion of steel.

It involves the application of a thin zinc layer to the steel surface by electro-deposition, metal spray, sherardizing, or hot-dipping method.

Read more: Galvanized Steel

The zinc used for galvanizing is nearly 100% pure. The thickness of the coating for the galvanized sheet is expressed in ounces/ square foot, one oz/ sqft being equivalent to a layer of zinc 0.0017-in. thick.

The protective layer on hot-dip galvanized steel & is pure zinc on the outer surface, under which are & iron-zinc alloys with progressively increasing iron & content. After the pure zinc outer surface has corroded, the underlying iron-zinc alloys continue to protect the steel.

Welding Galvanized steel

Galvanized sheet with a carbon content of less than 0.2% and sheet metals does not present any special welding problems.

“Galvanized sheet with a carbon content of less than 0.2% & sheetmetals does not present any special welding problems. “

— Material-welding

However, the lower maintenance costs of galvanized steel structures, such as bridges and storage tanks, have created a demand for galvanized materials in thicker sections and with higher tensile strengths with increased carbon content.

In general, galvanized plate over l/4 in. thick has poorer weldability than the equivalent uncoated steel.

Welds in the galvanized plates have a tendency for porosity; small cracks are likely to develop in fillet welds. The porosity is usually within acceptable limits, but the cracking may pose a difficult problem.

Cracking issue with Galvanized steel

Investigations have established that weld-metal cracks in galvanized steel are intercrystallite with a zinc-rich layer lining the surface of the crack.

Batch galvanized plates do not have a uniform coating of zinc, and the cracking may, thus, occur to a varying degree associated with the varying thickness of the coating.

Most, if not all, of the cracking, can be eliminated by removing the zinc before welding. The following methods, some of which are slow and costly, are recommended:

- Use shearing or torch-cutting sheet part after galvanizing.

- Prepare weld bevel after galvanizing is completed.

- Use flame heat to burn the zinc coating in the welding area before weld.

- Clean the zinc coating by grinding or shot-blasting.

In fillet welds, restrain can cause weld cracking. The tendency for this type of cracking increases as the plate thickness increases. To reduce restraint, fit the joint with a small gap. This practice not only reduces the restraint but also provides a means for the volatilized zinc to escape.

Stick Welding Galvanized Steel

- Use E6013 electrodes DCEP, with the same electrode size and current as recommended for uncoated steel. E6011 stick welding rod can also be used with AC polarity.

- Weave the arc parallel to the welding direction ahead of the Weld Crater. This procedure volatilizes the zinc.

- It is important to clear the zinc completely otherwise it will create porosity and cracks in the weld.

- On galvanized plates 1/4 inches or more in thickness, there could be an issue or lack of penetration with fillet welds.

- It is good to use a bigger diameter electrode according to the material thickness and welding position. With a whipping motion, concentrate on volatilizing the zinc ahead of the crater.

- For complete penetration, butt joints on galvanized plates require slightly more gap compared to those used with uncoated steel plates.

- Considerable spatter occurs when welding galvanized steel, but an anti-spatter compound applied in the area of the weld reduces the difficulty of removal.

MIG Welding Galvanized Steel

MIG Welding also can be applied on galvanized sheets and plates for welding application.

- Use ER70S-6 MIG wire for welding the galvanized steel. The short-circuiting transfer is used on sheets as it offers low heat input and avoids burn-through issues.

- Use 80- 110 ampere for 1/16 inch sheet thickness. Sheets with zinc coatings thicker than those covered in the table require higher currents, lower speeds, or both. A tendency for burn-through may require a slight side-to-side oscillation of the torch.

- The same problems of porosity, cracking, and spatter encountered with Stick Welding are present with gas metal-arc welding, and the same corrective measures are used. With proper adjustment of the power source, the spatter can be reduced but not eliminated.

Welding Galvanized Steel to Mild Steel

Welding of galvanized steel to mild steel is carried out using the same method as explained above.

When welding galvanized steel to mild steel with stick welding, use the E6013 type electrode.

MIG and TIG welding of galvanized steel to mild steel is carried out using ER70S-6 or ER70S-2 type filler wire.

Preheating is usually not needed for galvanized steel due to sheet metals that have low thickness only.

Welding Galvanized Steel to Stainless Steel

Stick Welding is done using an E309L type rod to weld galvanized steel to stainless steel. Before welding, clean the area by grinding.

TIG & MIG welding of galvanized steel to stainless steel is carried out using an ER309L rod.

Always clean the galvanized steel using a grinder or emery paper in case the grinder is not available before the welding operation.

If you will weld directly on galvanized steel, the zinc will evaporate and can cause welding porosity. So it is recommended to prepare the surface well before starting the weld.

Clean the final weld using a wire brush. Id required corrosion protection, zinc primer can be applied after welding or local galvanized is done on the welding area.

Health risks with Galvanized Steel Welding

Welding or cutting galvanized steel always produces zinc fumes. These fumes are toxic, and persons in the vicinity must be protected with proper ventilation or by some other means.

Use respiration PPE for welding galvanized steel. Zinc fumes can cause metal fever.

Safety when welding Galvanized steel

Always make sure to wear a respiration mask when welding galvanized steel to prevent inhaling the zinc fumes which are toxic.

When welding galvanized steel make sure to follow the following safety rules:

- Perform all welding in well-ventilated welding shop or area.

- Use good quality respiration mask.

- Do not touch hot parts.

- Use a respiration mask even while performing grinding activities.

- Use all welding PPE such as gloves, welding helmet, safety shoes, heat pad, etc.

What is best welding rod for Galvanized steel?