What is Polarity in Welding?

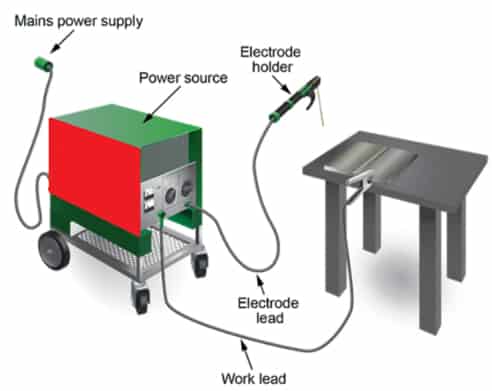

Polarity in welding is an important factor to consider when joining two pieces of metal together. The type of electrode used (basic or cellulose or rutile), the power source (AC, DC or pulse), and the shielding gas all play a part in determining the polarity of a welding process.

The type of polarity used will determine the amount of heat that is generated during the welding process, and how well the two pieces of metal will adhere to each other in term of weld penetration.

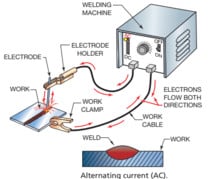

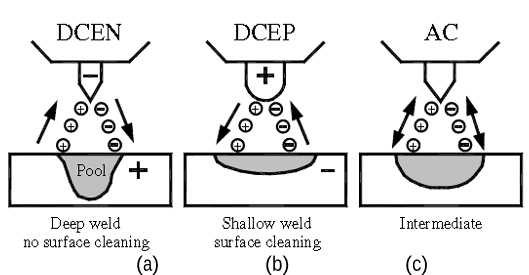

Most welding processes use direct current (DC), which means that the electrons flow in one direction only. AC polarity is used for materials with oxide layer.

Types of Polarity

There are two types of polarity that can be used in welding:

- direct current (DC) and

- alternating current (AC).

Most welding machines have the ability to weld using either direct current (DC) or alternating current (AC), but some can also use both AC Polarity and DC Polarity.

The type of current used for welding has a big impact on the quality of the weld, as well as the speed and ease of welding.

DC Welding Polarity

When it comes to DC welding, polarity is an important concept to understand. The reason for this is that the direction of the current flow can have a big impact on the quality of the weld.

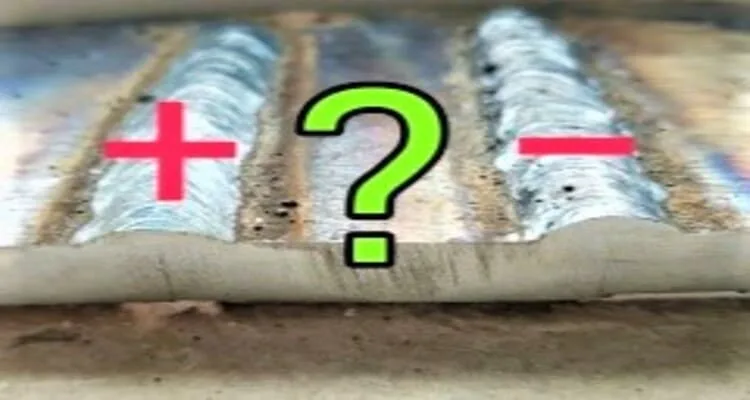

The two types of DC polarity are known as straight polarity and reverse polarity. Their full form are:

- Straight Polarity, also called Direct Current Electrode Negative (DCEN) or DC Negative Polarity.

- Reverse Polarity, also called Direct Current Electrode Positive (DCEP) or DC Positive Polarity.

Polarity should be chosen based on the type of metal being welded, the thickness of the metal, and the desired results. Using the wrong type of polarity can result in a poor weld, or even damage to the equipment.

DC Reverse Polarity

If you work with DC power on a regular basis, it’s important to know about DC reverse polarity. This is when the positive and negative terminals of a DC power source are connected in a specific manner.

In DC reverse polarity, welding rod is connected to the positive terminal of the machine and workpiece is connected with the negative terminal. 6010, 6011, 6013 and7018 welding rod is used mainly with DC Reverse polarity for good welding result.

DC Straight Polarity

DC Straight Polarity, also known as DCEN polarity refer to the polarity where welding rod is connected to the negative terminal of the machine and workpiece is connected with the positive terminal.

So in DC Straight polarity, the electrode is negative and the workpiece is positive. DC Straight Polarity is used for 6013, 7014, and 7024 welding rods.

Which type of polarity is used in welding non ferrous metals?

DCEP polarity is used for welding non-ferrous metals when welding with stick welding (SMAW).

However, when welding non-ferrous metals with TIG welding, DCEN or pulse polarity in mainly used. with MIG welding of non ferrous metals, DCEP polarity is used.

So, the three types of polarity used in welding non ferrous metals are are direct current (DCEP), alternating current (AC), and pulsed direct current (DC).

When smaw welding on carbon steel what polarity is most commonly used?

When smaw welding on carbon steel what polarity is most commonly used? – the most used welding polarity is Reverse polarity.

If you are using a covered electrode, the recommended practice is to use the reverse polarity, or also called Electrode positive polarity.

However, some electrodes can be used with either Straight or Reverse polarity (e.g., E6013, E7014, E7024). The choice of electrode and power source will determine which polarity should be used.

Which polarity used in welding cast iron?

DCEP polarity is used in welding cast iron. Cast Iron welding rods such as Nickel 55 and Nickel 99 are welded with Reverse polarity (Electrode positive) only.

When welding cast iron, it is important to use the correct polarity. If the wrong polarity is used, the weld will not be strong enough and could break easily.

Cast iron is a difficult metal to weld because it contains a high level of carbon. The carbon makes the metal very hard, but also very brittle.

Which type of polarity used in bare wire electrode?

There are two types of polarity used in bare wire electrode, direct current (DC) and alternating current (AC).

DC is the most common type of polarity used in bare wire electrode when using bare wire electrode with MIG & TIG welding.

AC is less common but has some advantages over DC and mainly used for welding bare wire electrode for Aluminum welding and magnesium welding.

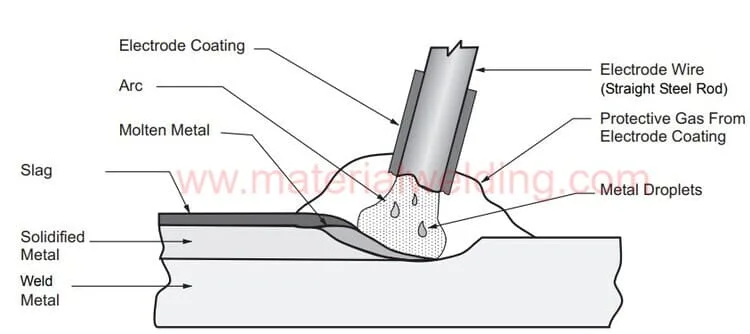

What polarity is used for gtaw?

The gas tungsten arc welding process uses an electrode made of tungsten, which is non-consumable. The way we connect this electrode in GTAW (TIG welding) defines its polarity.

Mainly DCEN and AC polarity is used for GTAW or TIG welding.

The welding current can be either direct current (DC) or alternating current (AC). When using DC, the electrode has a negative charge and the workpiece has a positive charge. This is called “reverse polarity.” When using AC, the polarity reverses itself periodically.