What is Stick Welding or Shielded Metal Arc Welding (SMAW)?

Stick welding or also known as SMAW stands for Shielding Metal Arc Welding (In Canada/ America/ India). Stick welding or SMAW is also called MMAW or Manual Metal arc welding (In the UK).

Other names are Electrode welding or Manual Welding. (Non-standards names which are common worldwide). In summary, the names of Stick Welding are:

- Shielding Metal Arc Welding or SMAW

- Manual Metal arc welding or MMAW

- Manual welding

- Arc welding or electrode welding

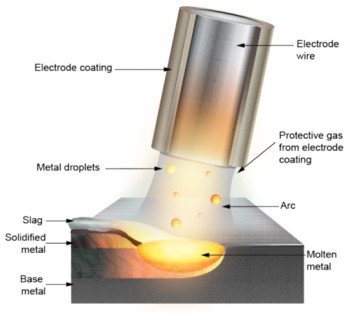

In Stick Welding or SMAW, the heat for welding is generated by the welding arc between the welding rod and the workpiece.

The electrode is fed manually to burn and that results in a weld metal deposit. The coating elements present on the welding rod burn and create shielding gases around the arc that protect the weld pool, welding arc from atmospheric oxidation and contamination.

The working of stick welding is explained in the below video in detail.

Watch this YouTube video for the full best classroom training on the Shielded metal arc welding process.

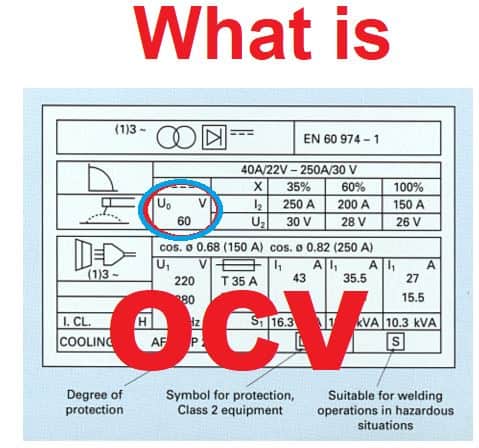

Figure 1 Process Principle

Which gas is released in the SMAW process causing a shielding affect on the molten weld pool?

In Stick welding or SMAW welding, the burning of electrode coating produces shielding gases such as Carbon dioxide (CO2), Carbon mono-oxide (CO), hydrogen (H), and oxygen (O). The majority of gases are carbon dioxide (CO2) and carbon mono-oxide (CO).

Carbon dioxide is created due to the burning of celluloses and calcium oxides present in the coating.

For example, in E6010 or E7010 type cellulose electrodes, a high amount of cellulose is present, which produces a high amount of CO2 which in turn goes through disassociation (breaking in Carbon & oxygen) due to arc heat and releasing more heat.

This is the reason for the very strong arc force in E6010 type welding rods.

Stick Welder/ SMAW Welding machine Setup

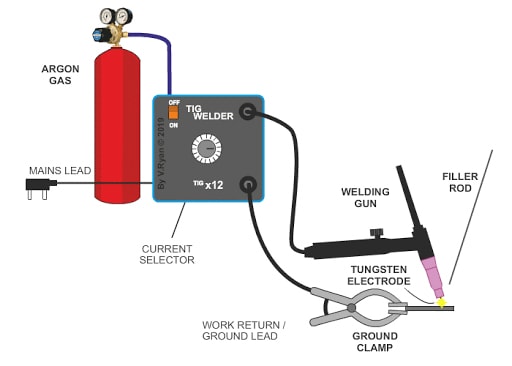

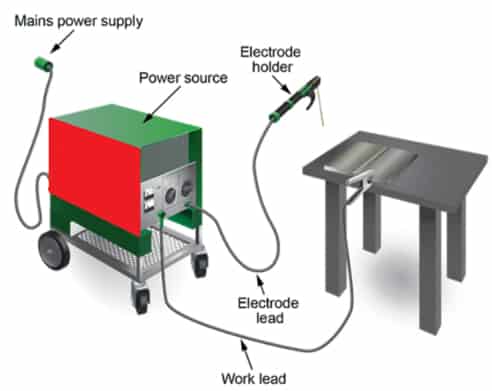

The basic components of the SMAW equipment setup (Figure – 2) are the following;

- Power Source or welder

- Electrode Holder

- Electrodes

- Cables/Lead

- Earthing clamp & work clamp

Please see the above schematic diagram (Figure – 2) of SMAW for a better understanding.

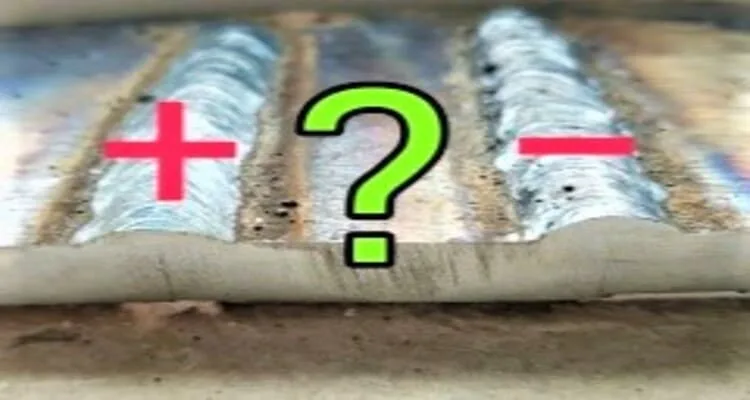

The welding machine is connected to the power supply. Stick welding electrodes can be connected to negative or positive terminals as per the electrode characteristics.

For example, the E7018 electrode is used only with DCEP or AC polarity. In Stick welding or SMAW three types of the main polarity are used as:

- Direct Current Electrode positive (DCEP) or Reverse Polarity,

- Direct-current electrode negative (DCEN) or straight polarity,

- Alternating Current.

A power source, electrode holder, welding handheld shield, and a wire brush for cleaning are shown in the figure below.

Functions of stick welding electrode coating

The main functions of Stick welding Electrode Coating or SMAW electrode coating are:

- To provide shielding to the weld pool, welding arc & electrode tip.

- Increase the electrode weld deposit efficiency. E.g. by adding iron-powder in the electrode coating.

- Addition of alloying elements to the weld where core wire is kept of mild steel material.

- Provide the arc stability.

- Gives easy removal of slag.

- Help to slow cooling of the weld by forming a slag layer.

- Increasing the arc power for deeper penetration. E.g. in cellulose electrodes (E6010/ E7010).

- Improve toughness properties. E.g. basic coating offers highest weld toughness properties.

- Define electrode polarity. E.g. potassium base for DCEP and titania for DCEN polarity.

Welding Parameters for SMAW Welding

Typical welding current (Amperage) ranges for shielded metal arc welding (SMAW) electrodes are given in the below table.

| Electrode diameter mm (in) | E6010 E6011 | E6012 | E6013 |

|---|---|---|---|

| 1.6 (1/16) | – | 20-40 | 20-40 |

| 2.0 (5/64) | – | 25-60 | 2560 |

| 2.5 (3/32) | 45-85 | 40-90 | 50-90 |

| 3.2 (1/8) | 75-125 | 80-140 | 80-130 |

| 4.0 (5/32) | 110-170 | 110-190 | 105-180 |

| 5.0 (3/16) | 155-235 | 155-265 | 165-250 |

| 6.0 (1/4) | 190-290 | 225-360 | 225-315 |

| 8.0 (5/16) | 275-245 | 300-500 | 320-430 |

| Electrode diameter mm (in) | E7015 E7016 | E7018 | E7024 |

|---|---|---|---|

| 2.5 (3/32) | 70-120 | 80-110 | 110-160* |

| 3.2 (1/8) | 110-150 | 115-165 | 140-190 |

| 4.0 (5/32) | 140-220 | 150-220 | 180-250 |

| 5.0 (3/16) | 200-280 | 220-350 | 250-335 |

| 6.0 (1/4) | 270-350 | 285-360 | 300-390 |

| 8.0 (5/16) | 375-475 | 375-470 | 400-525* |

Advantages of SMAW Welding

The main advantages of Stick welding/ SMAW are:

- Portable welding process.

- Suitable for outdoor welding application.

- Ease in use & out of position welding.

- External shielding gas is not required.

- Useful for working at height.

- Versatile applications.

Disadvantages of SMAW

The disadvantages or cons of Stick Welding/ SMAW are:

- Lower weld deposition rate.

- Require frequent slag cleaning.

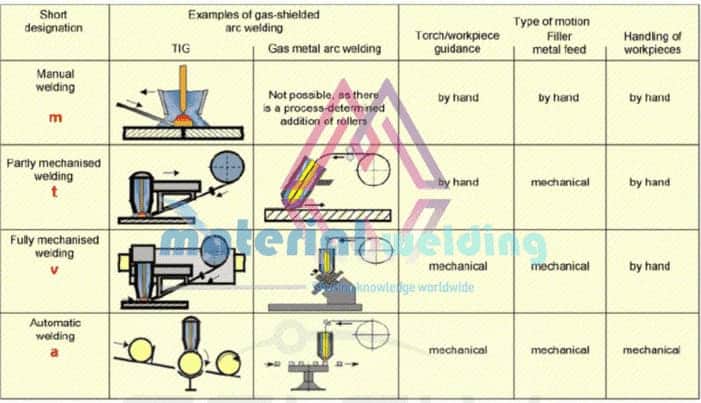

- Only manual welding operations.

- Requires repeated electrode change during welding.

- Not suitable for welding reactive metals such as Titanium, tantalum, Niobium etc.