Stick vs MIG or TIG

There is always confusion among most people while many argue on this topic- Does MIG or TIG is stronger than Stick welding or SMAW Welding? or Stick welding is stronger than MIG or TIG?

Are you one of those people, looking answer to this query.

First, let us know the difference between stick welding & MIG welding

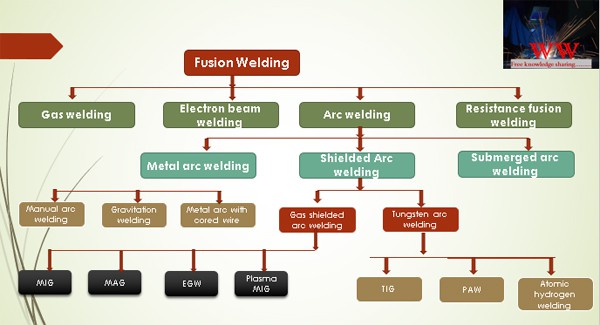

Both Stick welding or MIG welding is the type of arc fusion welding processes. Fusion welding processes are types of welding processes where heat for welding is generated by welding arc and material is melted to produce a weld fusion.

The difference between stick welding and MIG welding is the type of welding electrode either solid or flux-cored rod.

In stick welding, the welding electrode is a coated rod with flux usually having a length of 10 inches to 18 inches (depending on the type of electrode, carbon steel or stainless steel, and electrode diameters).

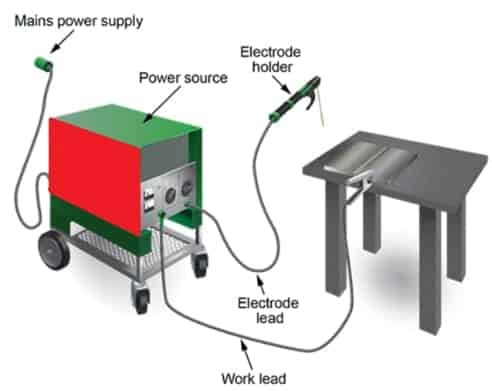

The electrode is held in an electrode holder connected to the welding machine. In stick welding, an arc is started by scratching the electrode on the workpiece and then maintaining an arc gap to complete the welding as shown in the below diagram.

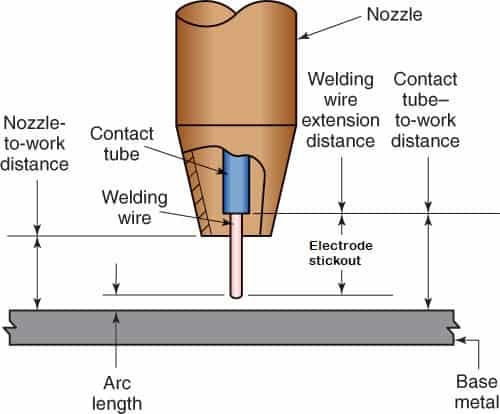

In MIG welding, the arrangement is different. Here the electrode is in the form of a spool of small diameter solid wire.

This spool is fitted to a wire feeder connected with the welding machine and fed to the workpiece via a welding torch connected with the wire feeder.

When the welder press the switch on the torch, wire is supplied from the wire feeder to the workpiece where it gets melted and produces a weld joint by fusion as shown in the below picture.

Stick Welding vs. MIG welding strength

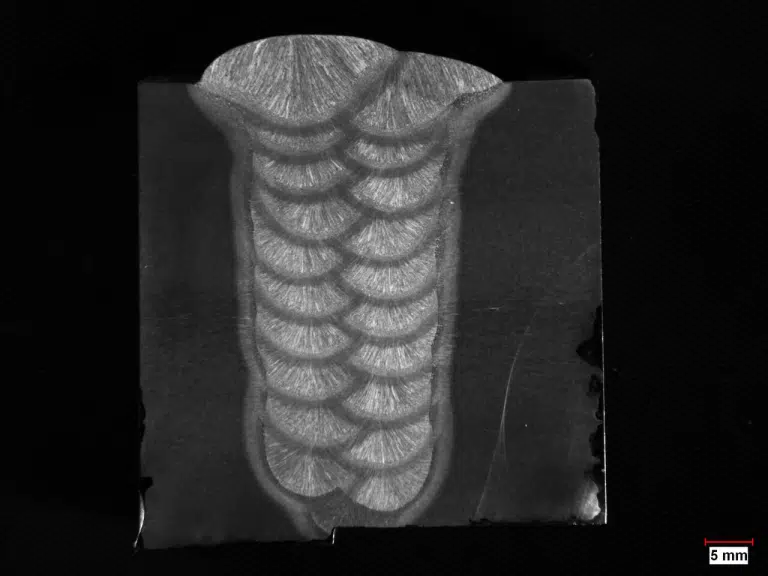

As stated earlier, both stick welding and MIG welding are types of fusion welding processes i.e. weld is formed by melting the welding wire in the weld pool and surrounding base metal.

So, the strength of the weld will depend on the filler wire or electrode strength and will not depend on what welding process you are using.

For example, you have carbon steel material of 30 Ksi strength and you welded it with a stick welding electrode of 40 Ksi strength, so the strength of the weld will be 40 Ksi.

Now, if you weld using the same material with a MIG wire of 40 Ksi strength, then also it will produce the same 40 Ksi strength weld metal.

As both the stick welding and MIG welding produce the weld by melting the filler wire or electrode or welding rod and nearby base metal.

So practically, both stick welding and MIG welding or TIG welding are equally strong. In general, the strength of the weld metal depends on the following factors:

- Welding rod strength.

- Welding quality, for example, weld-free from any defect will be stronger than weld with defects.

- Type of Welding Joint.

- Loading conditions.

So, it is the strength of the welding rod and the soundness of a weld deposit that decides the strength of weld metal and not the welding process.

Selecting a welding process for welding application

Selection of the welding process depends on:

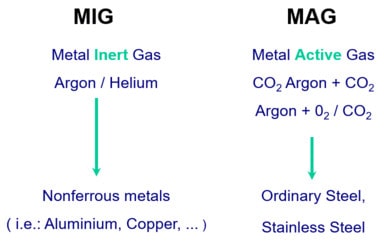

- type of material,

- available welding machine,

- welding location either site welding or workshop welding,

- availability of the welder,

- type of welding joint

- Weld productivity requirements.

- size of the part to be welded.

There can be other factors too, that can decide the type of welding process that can be used for welding applications apart from those listed above.

Similar Posts: