What is Brazing?

When comparing Brazing vs Braze Welding, Both Brazing & Braze Welding are joining processes having three distinct characteristics:

- Brazing uses a filler metal with a melting point above 840°F (450 °C) but less than melting point of the base metals.

- In Brazing there is no fusion of the materials being joined. Therefore, the filler has a different composition to the parts being joined.

- Brazing filler metal is drawn into the closely fitted joint faying surfaces by capillary action giving a thin film of solidified metal joining the work pieces.

- Heat is applied by an external heat source such as gas flame.

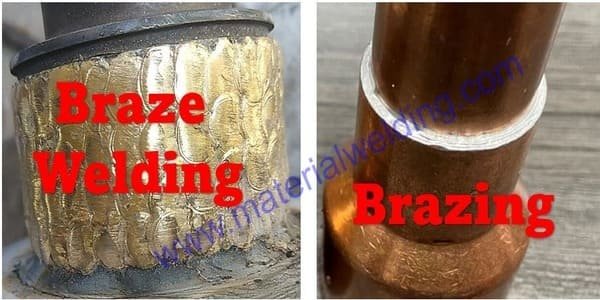

Condition 3 above applies specifically to brazing. If, conditions 1 and 2 above can be applied but with a substantial deposit of filler metal, the process is known as braze-welding.

Example of Braze Welding and Brazing are shown in the below picture.

What is Braze Welding?

Braze welding is similar to brazing process, and the only difference is the way of brazing filler wire deposition. During Braze welding, the welding rod is melted and deposited in a groove or fillet accurately in the area of joining.

There is no capillary action in braze weld like Brazing.

In Braze welding, the weld is deposited similar to weld-buildup without any capillary action. A flux is applied to the joining area to ensure bonding between the brazing wire and base metal.

Brazing Flux cleanout the surface impurities, protect molten pool from oxidation, support molten metal flow and ensure wetting of the joining area.

Types of Brazing Process

Brazing is a wide term that cover different brazing techniques to serve various joining objectives.

In industries, following brazing methods or types of Brazing Processes are used:

- Torch Brazing denoted by TB.

- Furnace brazing denoted by FB,

- Induction brazing denoted by IB,

- Resistance brazing denoted by RB,

- Dip brazing denoted by DB,

- Infrared brazing denoted by IRB,

- Diffusion brazing denoted by DFB.

What is brazing metal?

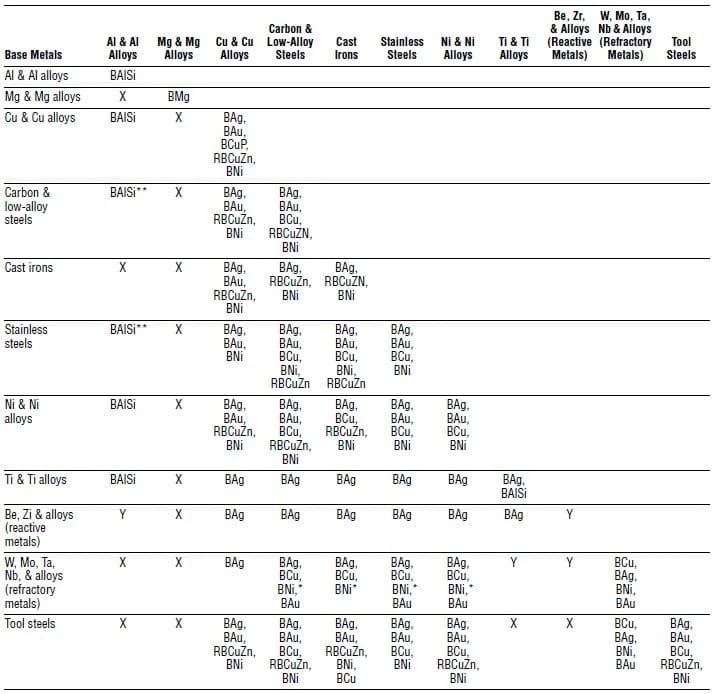

A detailed list of filler metals is contained within AWS A5.8 and ISO 17672: Brazing Filler metals. A Brazing Filler metals selection chart is given below to aid selection of right brazing filler wire for any material type.

Annex C of BS EN 14324:2004 provides guidance on what filler material to use for a given parent material combination.

Read my article to learn about Copper Brazing and Aluminum Brazing.

Annex D of BS EN 14324:2004 provides guidance on what filler metal can be used with the different brazing methods.

The brazing filler metals should have following properties:

- Melting point compatible with base metal.

- Adequate fluidity in molten stage.

- Ability for surface wetting during joining.

- Metallurgical suitability for base metal.

When selection filler metal for brazing check for:

- Joint design and type of base metal,

- Service conditions,

- Brazing temperature

- Heating technique available.

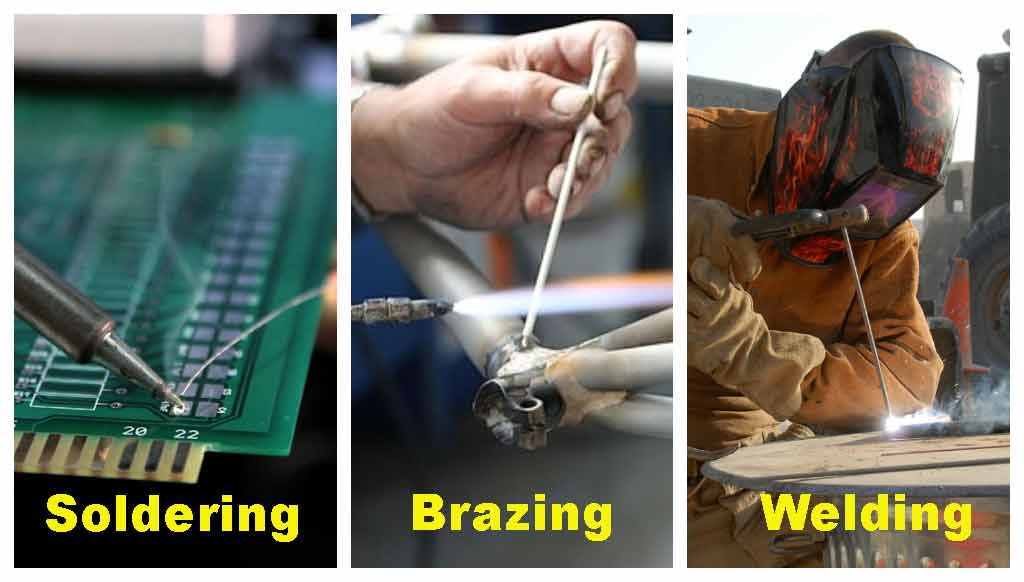

Brazing vs Welding vs Soldering

Brazing and soldering have similarity that base metal is not melted during joining and only filler metal is melted. While in welding, base metal and filler metals are melted and resolidified to form a weld joint.

Click here to read my article to lean in depth Brazing vs Welding vs Soldering.

Comparing Brazing vs Soldering, the main difference is the melting point of the filler metals. While in brazing the melting point of fillet metal is more than 840°F (450 °C) but for soldering filler metals the temperature is restricted to maximum of 840°F (450 °C).

Comparing Brazing vs. welding vs. soldering in terms of strength welding has the highest strength while the soldering has the lowest. Brazing strength fall in between soldering and welding.

Brazing vs Welding Strength

Many welders look answer for Brazing and welding strength for comparison. Simply, the welding has the higher strength compared to Brazing.

Many people want to know brazing vs welding bike frame. Should the brazing is a good option, or they go for welding?

The various reasons for this are:

- Welding filler wires has high strength compared to brazing. Welding wire strength directly represent weld metal strength.

- In welding penetration depth is more. This is another factor to decide weld strength.

- In welding fusion takes place by melting of base metal and filler metal, while in brazing it is solid state bonding.

Brazing Standards and Specifications

Following are the main Brazing Standards and Specifications used in the industries:

- AWS A2.4: Covers Brazing Symbols

- AWS A5.8: Specification for brazing and braze welding electrodes-Filler metals.

- AWS A5.31: Specification for brazing fluxes

- ISO 17672: ISO Standard for brazing filler metals.

- EN14324: Brazing guidance