Welding vs Brazing

Welding and brazing are two common metal joining techniques. They both have their own unique advantages and disadvantages, which can make them more or less suitable for certain applications.

Welding vs. Brazing can be differentiated basis:

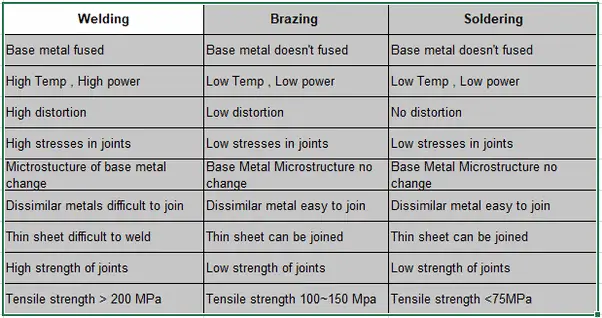

Welding is a process that uses heat to fuse two pieces of metal together- Both the base metal & filler wire are melted to produce a weld joint. It produces a strong, permanent joint and is often used in heavy-duty applications. However, it can be expensive and requires specialized equipment.

Brazing is a process that uses a filler metal to join two pieces of metal together & base metal is not melted– Only filler metal is melted. It is less expensive and less labor-intensive than welding, but the resulting joint is not as strong.

Welding vs. Soldering vs. Brazing

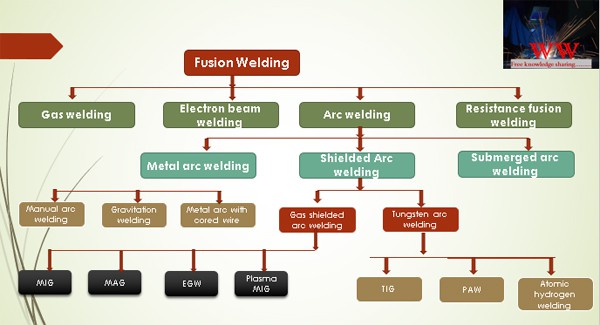

Welding, soldering, and brazing are joining methods to join materials. There are physical and technological differences between these terms although the main difference between welding, soldering, and brazing is melting temperature.

Soldering vs. Brazing

In soldering, and brazing metals are heated to a high temperature but they are not melted. While in welding, base materials are melted to produce a fusion welding joint.

Soldering actually includes applications similar to both braze welding and brazing. The main difference is in the melting temperature of the filler metal between soldering, brazing, and braze welding. Soldering occurs at temperatures below 449 °C (840 °F).

Traditionally, soldering uses different alloying’s of tin-lead alloys with melting points from 185 °C (361 °F) to slightly above 315 °C (600 °F). The mechanical strengths of soldered joints, mainly built-up joints of the braze-weld type, are low, and the most used for soldering is for providing fluid-tightness, for electrical connections, and for sheet metal joint in automobiles.

Soldering is similar to brazing as both work on the principle of capillary action to flow the molten filler metal to fill the joint and produce a permanent weld.

Welding vs. Soldering

The major difference between fusion welding and soldering is that, during soldering, the joining areas are wetted, the solder wire is molten, but the base material is not melted.

Technically correct in terms of materials, one would say that the liquidus temperature * (usually not even the solidus temperature *) of the base materials is not reached. Typical fusion welding is characterized by the fact that the liquidus temperature of the base and filler metals is exceeded.

In addition, it can be said that in the case of welding, the base and filler materials are quite similar and therefore the melting temperatures are almost identical. The connection mechanism also differs: When soldering, a diffusion zone forms in the area of the phase boundary, whereas melting takes place during welding.

Welding

The aim of welding is to create a very strong bond between two materials that can take weld loads, such as sheet metal joining or structural welding. During welding?

- Metallurgically suitability of metals to be joined: To weld two metals together, they must be similar or have metallurgical suitability for joining. For example, you can’t weld aluminum to steel although various dissimilar metals can be joined easily such as steel to copper, stainless steel to carbon steel, etc.

- High temperature: The temperature needed to weld two metals together must be quite high so they can melt and join. Welding low melting metals is not possible for example welding Lead.

- Filler materials: Welding can be carried out with filler or without filler. When welding without filler, it’s known as autogenous welding.

- Strength: The strength of the brazed joint can be very high if a proper brazing procedure is followed.

Soldering

Soldering visually appears similar to welding, although it is having different purposes. Soldering filler wire is soft compared to weld and melts at low temperatures.

The main application of soldering is for electronic circuits joining the electronic parts. As solder material is an electric conductor, it’s easy to join parts on the circuit board. In soldering, we shall have:

- Low temperature for soldering: Soldering is done at a low temperature where the part to be soldered is not melted.

- Filler materials: Soldering filler wires melt at below 840 °F (450°C).

- Dissimilar materials can be soldered: Dissimilar materials such as copper, silver, aluminum, gold or iron can be easily soldered to each other.

- Weaker joint compare to welding or brazing. Soldered joints are having weak strength because of low strength filler. Joints are not strong as welding or brazing but they fulfill their purpose by proving a good joining of different materials.

- Flux needs to be applied: Soldering flux is mandatory to clean the material surface, allow the melted filler to flow, and providing and better bonding.

(Minimum) overlap on soldered joints

When creating overlapped joints, basic requirements exist, which were originally developed for soldering but which were later also applied to brazed joints. In principle one dimension, depending on the minimum sheet thickness, applies for the minimum overlap length. The type of base metal also exerts an influence.

Base metals that can be soldered

In general, practically all metallic materials and their alloys can be soldered. The frequent, common main groups are:

Steels: Practically all steels are suitable for soldering, compared to welding, particularly while maintaining material-specific properties. The soldering temperature can be selected such that heat treatment can be integrated into the soldering process, (e.g. tempering, annealing, precipitation hardening etc.)

Aluminum: Nowadays, aluminum and aluminum alloys are brazed and (soft) soldered. Mixed joints are possible, thus, e.g., aluminum is very frequently mixed with corrosion-resistant, high-alloy steel.

Copper: Unalloyed copper, and low and high-alloy copper alloys, can be joined using brazing and soldering. Mixed joints with steel do not pose a problem either. Copper brazing is often restricted because of the issue of undesired softening of cold-formed or precipitation-hardened copper. The oxygen content in the copper determines whether it is suitable for soldering or even whether it can be soldered at all.

And Brazing

Brazing is similar to soldering and requires brazing wire as a filler for joining also the base metals are not melted like welding. Brazing is done at temperatures above 449 °C (840 °F). Brazing uses several varieties of filler material, which are chosen based on their application.

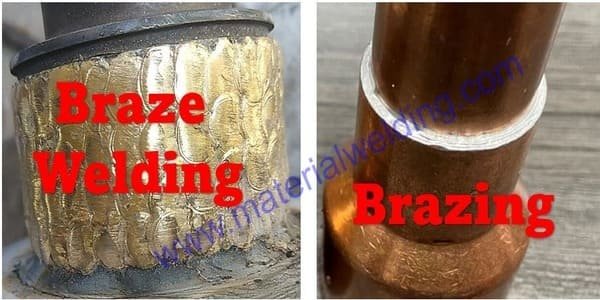

When we say only brazing, it’s meant to join using the same filler wire used for braze welding but here it is applied to a tight fit joint. The filler wire is either replaced or melted and fills the gap by capillary action. The filler material may be rod, wire, foil, slug, or powder, and fluxes similar to those used in braze welding is necessary.

The melting temperature of the brazing wire is higher than the soldering. Alike to welding, brazing produces a permanent joint between two materials. In brazing we shall have:

- Filler wire melt and fill the joint: The brazing process involves heating and melting of brazing filler wire. which after solidification join the two materials

- Filler materials with low melting temperature: In brazing, filler wire melt at a low temperature but higher than soldering.

- Dissimilar materials: Dissimilar materials such as copper, silver, aluminum, gold, or iron can be easily brazed to each other.

- Flux needs to be applied: Brazing flux is mandatory to clean the material surface, allow the melted filler to flow, and providing and better bonding.

- Weld joint Strength: A good braze weld can have weld strength slightly less than fusion welding. But they are quite strong in case of emergency repairs of cast iron, for example.