Unable to decide which type of welding is the strongest? Read this post as it outlines five of the most frequently used welding processes and their strengths.

Choosing the right type of welding for a job or project can be tricky. Each welding process has different strengths and weaknesses and is best suited to certain materials and shaped parts.

To help, here are five of the most popular welding processes and their strength comparisons.

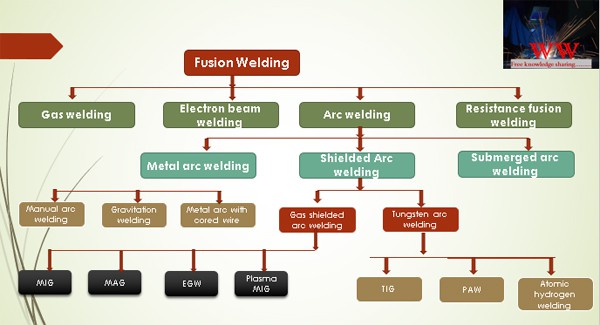

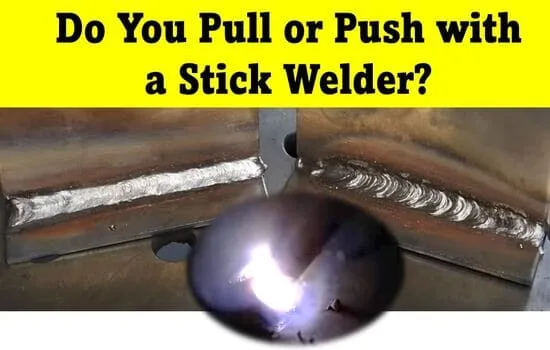

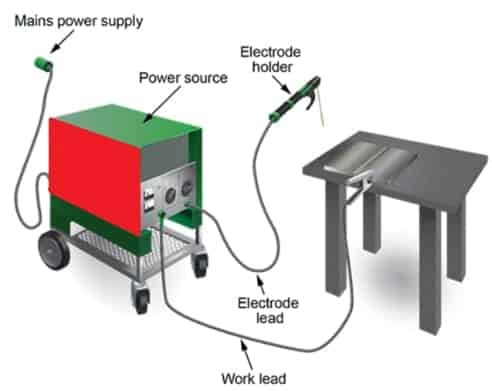

Stick Welding: Shielded Metal Arc Welding (SMAW)

Shielded Metal Arc Welding (SMAW), also known as “stick” welding, is one of the oldest and most widely used welding processes.

Stick welding is often used for welding thicker metals and in outdoor or remote locations where other welding techniques may not be feasible.

It offers relatively high strength welds with good penetration and is able to weld thicker materials than other processes.

SMAW is often used for outdoor projects where wind may interfere with gas welding.

It can also be used in situations where access to electricity is limited as it doesn’t require an external power source, such as a generator or compressor.

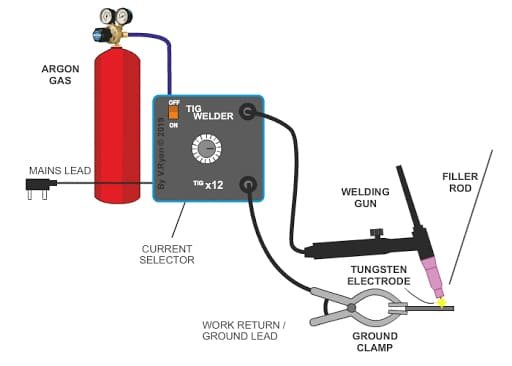

TIG Welding: Gas Tungsten Arc Welding (GTAW)

Gas Tungsten Arc Welding (GTAW or “TIG”) is one of the most versatile welding processes and produces very high quality, repeatable welds.

It can be used to weld a wide range of metals and alloys, including aluminum and stainless steel.

It also requires less heat than other welding processes and is ideal for delicate components that need to be kept cool when being welded.

This method produces high-quality, precise, and clean welds, making it the preferred method for welding critical structures like airplanes, race cars, and spacecraft.

The strength of GTAW welds depend on the base material – stainless steel welds are generally considered to be the strongest.

Flux-Cored Arc Welding (FCAW)

Flux-Cored Arc Welding, or FCAW, is a modified version of gas metal arc welding (GMAW) that eliminates the need for using shielding gases.

It’s highly versatile, and can produce stronger welds than GMAW when used on heavy walled steel pipes and sheets.

The main advantage of FCAW is its portability since it can be used in outdoor settings.

The increased availability of special flux-cored wires has also made it attractive for working with stainless steel, aluminum alloys, and other metals.

This method is often used in outdoor welding projects and is a popular method for welding thicker metals.

MIG Welding: Gas Metal Arc Welding (GMAW)

MIG Welding or Gas Metal Arc Welding, or GMAW, is a welding process that uses an electric arc created between a consumable wire electrode and the workpiece’s surface.

It operates through a continuous feed system which makes it suitable for industrial automation applications.

GMAW can be used on carbon steel, stainless steel, aluminum, copper, and magnesium alloys.

The strength of the weld is determined by the type of electrodes used in the process; some electrodes are significantly stronger than others depending on the metal being welded.

This method is fast and efficient, making it the preferred method for large-scale production welding. It is also popular in automotive and industrial welding applications.

Submerged Arc Welding (SAW)

Submerged Arc Welding makes use of a continuously fed electrode, typically made up of flux-covered wire and held in two side-by-side rolls.

It is deposited into the weld joint as it moves across the surface. Often used for heavy duty welding, such as tanks and pressure vessels, Submerged Arc Welding is regarded as one of the best choices when it comes to strength.

The consistent depth and thickness of the weld make SAW an excellent choice for welding thicker sections.

Additionally, its strong penetration capabilities give it a high degree of weld strength.

So, which type of welding is the strongest?

TIG welding produces the strongest welds, followed by MIG welding. This is because TIG welding produces precise, clean welds that penetrate deep into the metal, making them very strong.

MIG welding also produces strong welds, but they are not as precise as TIG welds.

Stick welding and flux-cored welding produce welds that are less strong than TIG and MIG welds but are still suitable for many applications.

Which is the strongest weld mig, tig or stick?

MIG, TIG, and Stick welding are three of the most common types of welding. Each type has its own unique benefits and drawbacks that make it suitable for different applications.

To determine which is the strongest weld depends on a variety of factors such as quality of materials used and skill level of the welder.

Below table summarize, MIG, TIG, Stick and FCAW Welding on basis of various factors such as Strength, precision, speed, cost and applications.

Basis, its precision, high welding quality, deep penetration, and good weld pool properties, TIG welding is strongest among MIG, TIG, Stick and FCAW Welding.

| Welding Technique | Strength | Precision | Speed | Cost | Applications |

| TIG Welding | Very Strong | Very Precise | Slow | Expensive | Critical structures, Aerospace, Racing |

| MIG Welding | Strong | Less Precise | Fast | Moderate | Large-scale production, Automotive, Industrial |

| Stick Welding | Moderate Strength | Less Precise | Slow | Inexpensive | Construction, Repairs |

| Flux-Cored Welding | Moderate Strength | Less Precise | Fast | Moderate | Outdoor welding, Thick metals |

Related Reading: Stick Welding vs MIG Welding: Which is Strongest?

TIG vs MIG Welding

| Welding Technique | TIG Welding | MIG Welding |

| Process | Uses a tungsten electrode and separate filler rod | Uses a wire-fed welding gun and a wire filler |

| Precision | Very precise | Less precise than TIG welding |

| Strength | Very strong | Strong |

| Speed | Slow | Fast |

| Difficulty | Difficult to master | Easier to learn than TIG welding |

| Applications | Critical structures, Aerospace, Racing | Large-scale production, Automotive, Industrial |

Conclusion

In Conclusion, we can summarize these welding processes as:

TIG Welding:

- Uses a tungsten electrode and separate filler rod to produce high-quality, precise, and clean welds.

- Penetrates deep into the metal, making it suitable for critical structures like airplanes, race cars, and spacecraft.

- Produces the strongest welds among the different welding techniques.

- Generally more expensive and slower than other welding techniques.

- Requires a high level of skill and experience to master.

MIG Welding:

- Uses a wire-fed welding gun and a wire filler to join two pieces of metal.

- Produces strong and efficient welds that are less precise than TIG welds.

- Ideal for large-scale production welding in industries like automotive and industrial manufacturing.

- Generally faster and less expensive than TIG welding.

- Easier to learn and master than TIG welding.

Stick Welding:

- Uses an electric current to create an arc between the welding stick and the metal to be welded.

- The stick provides the filler material to join two pieces of metal.

- Ideal for construction and repair projects.

- Produces welds that are less strong and less precise than TIG and MIG welds.

- Generally less expensive but slower than MIG welding.

Flux-Cored Welding:

- Uses a wire with a flux core to shield the weld from the air.

- The flux core melts and forms a protective shield around the weld.

- Ideal for outdoor welding projects and welding thicker metals.

- Produces welds that are less strong and less precise than TIG and MIG welds.

- Generally faster and less expensive than TIG welding, but more expensive than MIG welding.