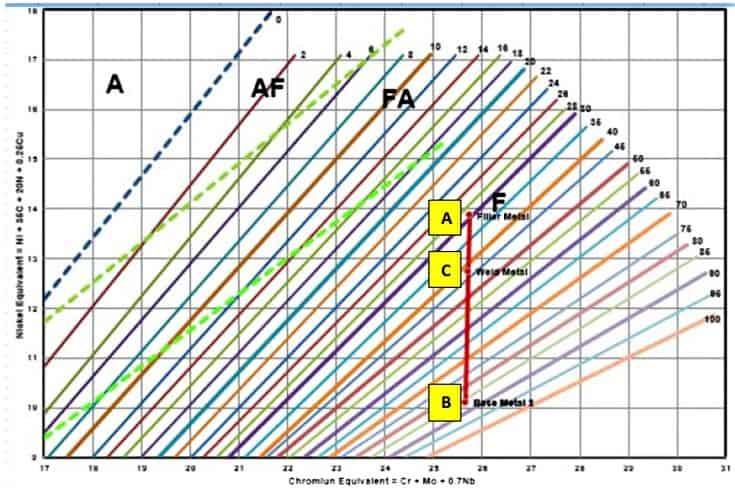

To calculate the Ferrite Number (FN) from the Ferrite Percentage (%), you can use the following steps:

- Obtain the Ferrite Percentage (%): This can be determined through various methods such as microstructural analysis, chemical analysis, or using specialized instruments.

- Determine the steel type: Different steel types have different conversion factors between Ferrite Percentage and Ferrite Number. Identify the appropriate conversion factor based on the specific steel type.

- Apply the conversion formula: Use the conversion factor to calculate the Ferrite Number (FN) from the Ferrite Percentage (%). The formula is typically of the form: FN = Ferrite Percentage / Conversion Factor.

- Perform the calculation: Divide the Ferrite Percentage by the Conversion Factor to obtain the Ferrite Number.

For example, let’s assume we have a 25% Cr duplex stainless steel with a conversion factor of 0.65. To calculate the Ferrite Number (FN), we can use the following equation:

FN = Ferrite Percentage / Conversion Factor

= 25 / 0.65

= 38.46

Therefore, the Ferrite Number (FN) for this particular steel would be approximately 38.46.

Ferrite Percentage to Ferrite Number Calculator

Ferrite Percentage to Ferrite Number Calculator

What is Ferrite in Stainless Steel?

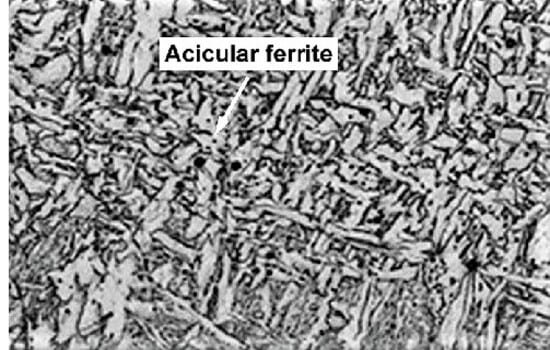

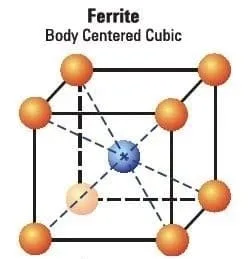

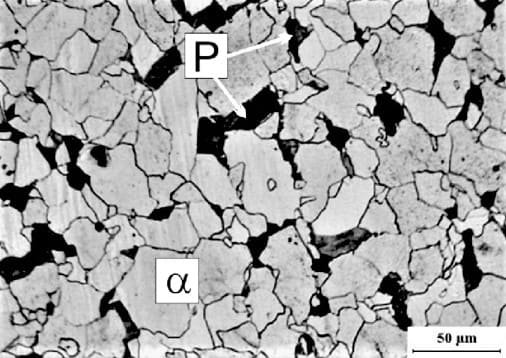

Ferrite is a phase that exists in stainless steel. It is a solid solution of iron and other alloying elements, primarily chromium, in which the crystal structure is body-centered cubic (BCC). Ferrite is magnetic and has a relatively low carbon content.

In stainless steel, the presence of ferrite can have various effects on the material's properties. Some key points about ferrite in stainless steel are:

- Stability: Ferrite is stable at high temperatures and remains in the steel structure even in elevated temperature conditions.

- Corrosion Resistance: Ferritic stainless steels, which have a higher ferrite content, exhibit good resistance to stress corrosion cracking and certain types of corrosion, such as chloride-induced pitting corrosion.

- Strength and Ductility: Ferrite contributes to the strength and ductility of stainless steel, providing a balance between these properties.

- Magnetic Properties: Due to its crystal structure, ferrite is inherently magnetic. The magnetic behavior of stainless steel depends on the amount and distribution of ferrite within the material.

What is Austenite in Stainless Steel?

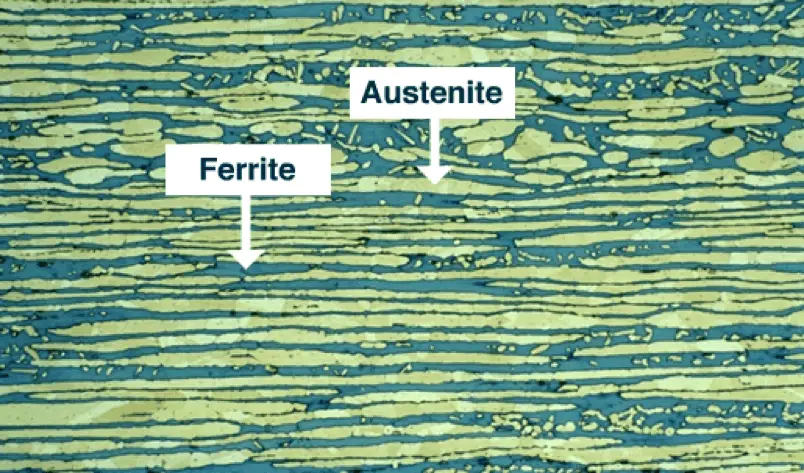

Austenite is a crystalline phase that is commonly found in stainless steel. It is named after Sir William Chandler Roberts-Austen, a metallurgist who extensively studied and classified steel microstructures. Austenite is characterized by its face-centered cubic (FCC) crystal structure, which provides stainless steel with its unique properties.

Key Features of Austenite:

- Composition: Austenite is primarily composed of iron (Fe) and alloying elements such as nickel (Ni) and manganese (Mn). It is non-magnetic in nature due to its FCC crystal structure.

- Stability: Austenite is stable at high temperatures, typically above 912°C (1,674°F), known as the austenite phase transition temperature. In this range, stainless steel remains in the austenitic phase.

- Corrosion Resistance: Austenitic stainless steels, which predominantly consist of austenite, exhibit excellent corrosion resistance due to the presence of alloying elements like chromium (Cr) and nickel (Ni). These elements form a protective oxide layer on the surface, known as the passive layer, which helps prevent corrosion.

- Ductility and Toughness: Austenitic stainless steels possess good ductility and toughness, making them suitable for various forming and fabrication processes. They can be easily shaped, welded, and machined.

- Non-Magnetic Behavior: Austenitic stainless steels are generally non-magnetic in the annealed condition due to the FCC crystal structure of austenite. However, certain cold-working or strain-hardening processes may induce some magnetic properties in austenitic steels.

Ferrite vs Austenite

| Characteristic | Ferrite | Austenite |

|---|---|---|

| Crystal Structure | Body-Centered Cubic (BCC) | Face-Centered Cubic (FCC) |

| Composition | Iron (Fe) and Chromium (Cr) | Iron (Fe), Chromium (Cr), Nickel (Ni), and Manganese (Mn) |

| Magnetic Properties | Weakly Magnetic | Non-Magnetic |

| Corrosion Resistance | Good | Excellent |

| Phase Transition Temp. | N/A | Above 912°C (1,674°F) |

| Ductility and Toughness | Lower | Higher |

| Weldability | Excellent | Excellent |