What is Carbon equivalent in welding?

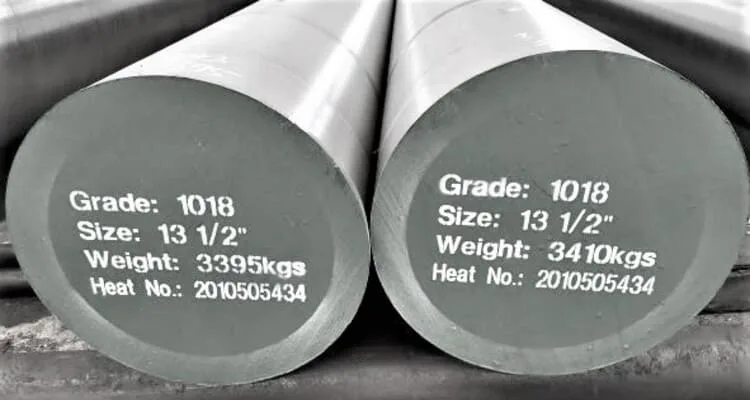

The Carbon Equivalent or also called the C.E. is a measurement of weldability factors for ferrous materials such as Carbon steel, Low alloy steel, C-Mn steel, and cast iron.

Carbon equivalent is an important tool to determine the different properties (e.g. predicting the hardness, weldability & microstructure) of the alloy when more than just carbon (C) is used as an alloying element. C.E. calculation is used in welding, heat treatment, and casting processes.

In other words, C.E. can be counted as the prediction of martensite formation in the weld metal during solidification and face brittle fracture due to high hardness.

Carbon Equivalent (C.E) is used in welding to define the weldability of steel and to know how the different alloying elements influence the hardness & microstructure of the material that has to be welded.

Considering the C.E. value hydrogen-induced cold cracking of cold cracking in the weld can be predicted according to the EN1011-2.

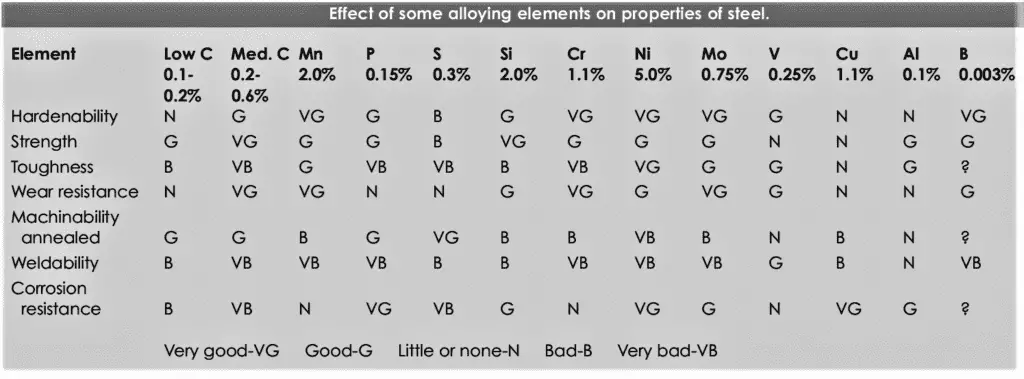

It is evident that increasing the amount of carbon & other added alloying elements for Silicon, chromium, manganese, Vanadium, etc. (refer below table for complete details) gives rise to hardness & reduces alloys weldability.

In steel alloying metallurgy, each alloying element has its beneficial and detrimental effects on various properties as highlighted in the below table.

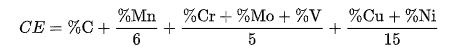

Welding engineers & metallurgist uses two widely used C.E. calculation formulas given by the Americal welding society (AWS) and the International Institute of Welding (IIW).

Value of Carbon equivalent is used in combination with hydrogen in welding and material thickness to predict the preheat temperature in steel and cast iron. Usually, a carbon equivalent of more than 0.4% requires material to be preheated before welding.

According to the AWS guidelines, with a C.E. content of more than 0.40%, the welding is prone to cracking in the heat-affected zone (HAZ) and in the welding. The American welding Society (AWS) carbon equivalent (C.E.) calculation formula is given below:

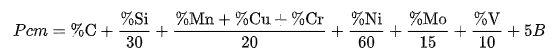

Pcm formula for carbon Equivalent

The Japanese Welding Engineering Society adopted the critical metal parameter (Pcm) for weld cracking, known as the Pcm formula.

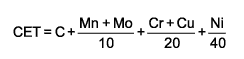

CET formula for Carbon Equivalent

The CET formula is designed in considering similar elements to the CEIIW formula. The main exception is the Vanadium. But in this formula, carbon is considered to have more significant effect compared to other elements.

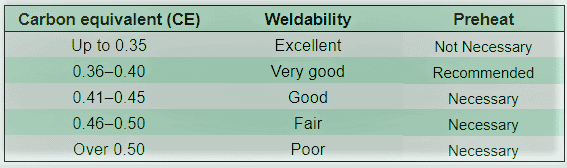

Relationship between Carbon Equivalent and Weldability of Steel

Carbon equivalent directly affects the weldability of the materials. As the C.E. values increases, the weldability of the materials decreases. Materials with low carbon equivalent offer excellent weldability with minimum precautions.

This precaution such as additional welding preheat, use of low hydrogen electrodes, post-heating, etc. increases as the value of C.E. increases.

The below table shows the relationship between carbon equivalent (C.E.) value, material weldability, and preheat requirements.

To calculate easily and accurately carbon equivalent based on IIW, AWS, Pcm, and CET, in one step instantly use our online calculator. Click on the below link.

Online carbon equivalent calculator, CET & CEV calculator (materialwelding.com)