What is 34CrNiMo6

EN 24 or 34CrNiMo6 is a quenched & tempered (Q &T) alloy steel as per EN 10083-3 available in rod, bar, strip, plate, and forging materials.

Due to the high carbon and alloying elements such as Chromium, Moly & Nickel (alloyed to improve response to heat treatment).

EN 24 is highly sensitive to the heat treatment process and prone to air hardening when heating to high temperatures very easily.

EN 24 or 34CrNiMo6 is used for parts that require high strength and toughness such as shafts and gears etc.

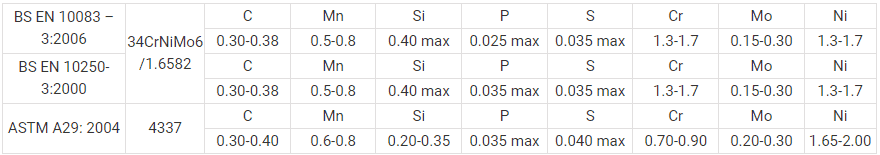

EN 24 or 34CrNiMo6 Equivalent materials & grades

ASTM equivalent material & grade of EN 24 or 34CrNiMo6 is ASTM A29-4337. The steel designation number of EN 24 is 1.6582.

34crnimo6 equivalent is ASTM A29-4337 and EN24 (1.6582).

Chemical & mechanical properties of EN 24 or 34CrNiMo6

The chemical properties of EN 24 or 34CrNiMo6 are given in the below table. EN 24 or 34CrNiMo6 has carbon in the range of 0.3% to 0.38%, Mn 0.5% to 0.8%, Chromium & Ni 1.3% to 1.7% and Mo 0.15% to 0.30%.

The mechanical properties of EN 24 or 34CrNiMo6 vary with the thickness. For thickness up to 16 mm, the material minimum yield strength is 145 Ksi (1000 N/mm2) and Tensile strength in the range of 175- 203 Ksi (1200- 1400 N/mm2). The average toughness (CVN) required in Joules is 35 -45 Joules.

34CrNiMo6 vs 4340

Both the materials are Quenched and tempered materials having high tensile strength and toughness.

Both AISI 4340 or EN24 (34CrNiMo6) materials are high carbon alloys, alloyed with Cr, Mo & Ni making them air-hardenable having tempered martensite microstructure.

Welding Electrode/ Filler wire for EN 24 or 34CrNiMo6

Due to the high carbon content and other alloying elements, the welding of EN24 material is a difficult task although not impossible.

A number of precautionary steps need to be implemented before the start of the welding. Welding of EN24 (34CrNiMo6) that have a Carbon Equivalent in the range of 0.5-1.1 requires high preheat temperature before welding & during welding followed by slow cooling.

SMAW or stick welding can be carried out using E7018 (E51 5B 120 20H as per ISO 2560) or E 9018-G as an undermatching rod or with E11018-G (ISO 18275-A: E 69 4 Mn2NiCrMo B 42 H5) matching strength rod.

Austenitic base electrodes such as E309Mo or E307-15 can also be used for welding EN24 (34CrNiMo6).

MIG welding is carried out using ER100S-G (ISO 16834-A: G Mn3Ni1CrMo) filler wire. Pure argon is used for shielding the weld pool.

Gas purging or backing is not required for EN24 welding with TIG or MIG welding due to the low amount of chromium in the alloy.

Preheat & interpass temperature

EN 24 or 34CrNiMo6 requires high preheat temperature in the range of 300- 400°C.

The stress relief annealing if requires shall be carried out at a 450- 650°C temperature range with a soaking period of 2 hours.

Hardening is done at a temperature range of 820-850 °C followed by tempering at 540-680 °C. A right preheat and interpass control during the welding will ensure a controlled level of weld & HAZ hardness.