What is Combination Welding?

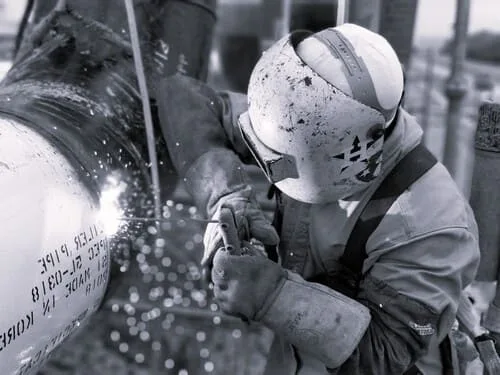

A combination welder also called a combo welder or multi-skill welder, is a welding professional who is skilled in multiple welding processes.

As we know, welding is a process of permanently joining two pieces of metal together and there are many different types of welding processes. The most common are oxy-fuel welding, Stick welding, gas tungsten arc welding (TIG), and MIG welding. Combo welders can do it all—they’re multi-skill welders.

Who is a Combo Welder?

A combo welder is a welder who is able to weld using more than one type of welding process. For example, a combo welder might be able to weld the root pass of a pipe groove weld using tig welding and then switch to stick welding for the fill and cap passes.

A combo welder is a skilled welder who is able to complete a job single handed using different welding processes. He/ She generally has many years of experience and is highly trained in all aspects of welding.

In most cases, a combo welder will have completed an apprenticeship or have a journeyman’s license.

A combo welder is a skilled tradesman who is able to operate multiple welding processes, including weld preparation, the root run welding, inspection, fill and weld capping. They are also able to read blueprints and follow instructions accordingly including weld visual inspection.

A combo welder is an invaluable asset on any construction site or in any manufacturing facility. They are able to quickly and efficiently complete jobs that would otherwise require multiple welders.

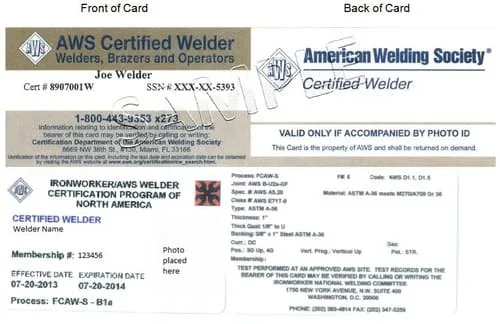

Combination Welding Certification

There are many welding certifications an individual can receive, but a combination welding certification is one of the most beneficial.

A combination welding certification indicates that the holder has the skills and experience to weld a variety of materials, using multiple welding processes. This type of certification is often required for positions in fabrication and construction.

Combo Welder Schools in Texas.

There are a few ways that one can become a certified combination welder or Combo Welder. The most common way is to join a welding school, master different welding processes, weld WQT and pass the test.

Welding schools will teach you the basics of welding, such as safety, metallurgy, and joining methods. You will also learn about the different types of welding processes, such as stick welding, TIG welding, MIG welding and gas cutting.

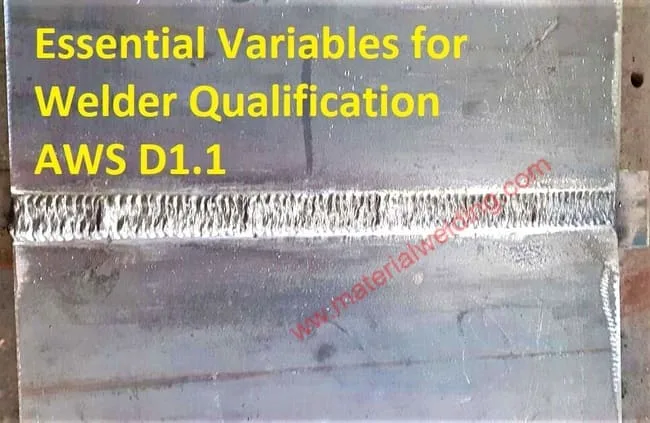

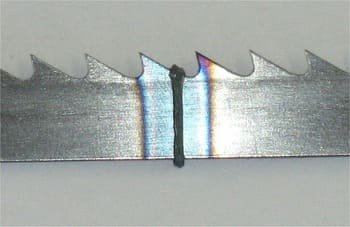

After you have mastered the different welding processes, you will be required to weld a test coupon, also called WQT using a combination of welding processes. This test piece is subjected to welding tests (e.g., radiography, bend test) to evaluate the weld soundness.

Advantages & Disadvantages of Combo Welder

Combo Welder Advantages |

|---|

| ✅ Versatility ✅ Higher output ✅ Cost saving ✅ Job accountability |

Combo Welder Disadvantages |

|---|

| ❌ High wages for company ❌ Need lot of experience ❌ Requires nos. of tools ❌ Need regular practices |

Salary of Combo Welders

Combo welders are in high demand due to their ability to weld multiple metals using a combination of welding processes.

They are able to weld aluminum, stainless steel, and mild steel. The salary of combo welders is based on the type of metal they are welding, their experience, and the company they work for.

Combo welders with little to no experience can expect to earn an hourly wage of $15-$25. Those with more experience can earn $25-$35 per hour. Combo welders who are certified can earn up to $45 per hour.

The salary of combo welders also depends on the location. Welders in rural areas usually earn less than those in urban areas. Combo welders in cities such as New York, Los Angeles, and Chicago can expect to earn the highest wages.

Combo Welder Resume Sample

If you’re in the market for a new welding gig, you’ll need a solid resume to land the job. Check out our combo welder resume sample for guidance on how to craft your own.

As a combo welder, you’re responsible for multiple welding processes such as stick welding, MIG and TIG welding, so it’s important that your resume reflects your experience with both types of welding.

In your professional summary, highlight your years of experience and any welding certifications you may have.

In the skills section of your resume, list any relevant welding software or equipment you’re familiar with. And don’t forget to mention your safety training! Be sure to include details of any projects you’ve worked on in the experience section, including the types of materials you welded and any special techniques you used.

Click this link to download the Combo Welder Resume sample. You can edit it to highlight and add your skills and personal information.