What is a Fillet Weld Gauge?

In Welding quality control, the prompt detection and resolution of flaws or process deviations can lead to significant cost savings for poor weld quality.

Visual Inspection using the welding gauge as a Nondestructive examination during welding is one of the most important monitoring method that ensures the weld’s mechanical properties & quality.

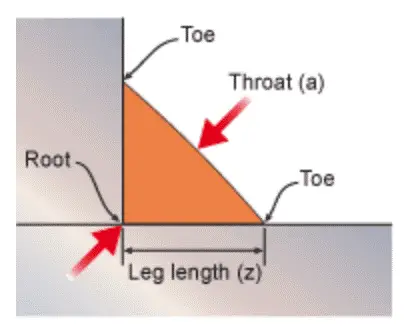

A Fillet Weld Gauge is an important tool for quality control and weld checking. It is used to measure the size of a fillet weld, which is the triangular weld bead created by two pieces of metal that have been joined by welding.

The size of the fillet weld is important because it affects the strength and quality of the weld. A fillet weld gauge can be used to check the size of a fillet weld after it has been completed as a final welding check.

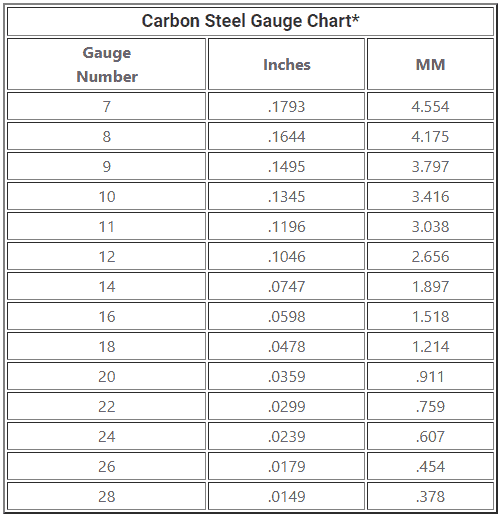

| Image | Product | Details | Price |

|---|---|---|---|

| Taper Gage 1/64”-5/8” Stainless Taper Welding Gauge Test Ulnar Inch & Metric Standard | Taper Welding Gauge 1/64”-5/8” (1-15mm) Both Inch and Metric Standard Made of Stainless Steel | CHECK PRICE |

| 7piece Fillet Weld Set Gage RL Gauge Welding Inspection Test | 7piece Fillet Weld Set Gage Metric Unit Stainless Steel Brand: RIVERWELD | CHECK PRICE |

| Bridge Cam Gauge Welding Fillet Throat Gage | Bridge Cam Gauge Welding Fillet Throat Gage, Leg length, Bevel angle measurement. Stainless Steel body | CHECK PRICE |

| V-Wac Gage Single Welding Gauge Inspection Metric Stainless Steel (Pit Gauge) | V-Wac Gage Inch/ Metric Standard Made of Stainless Steel | CHECK PRICE |

| Automatic Weld Size Fillet Weld, Butt Weld Gauge | Automatic Weld Size Fillet Weld Butt Weld Gauge Metric Unit Stainless Steel Brand: RIVERWELD | CHECK PRICE |

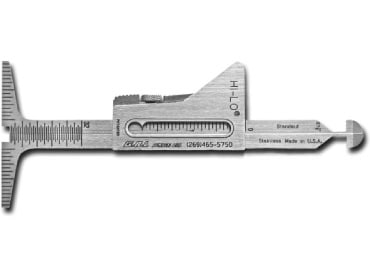

| Hi Lo Welding Gauge Gage | Hi-Lo Welding Gauge Gage Both Inch and Metric Stainless Steel body | CHECK PRICE |

| Adjustable Fillet Weld Gauge | Adjustable Fillet Weld Gauge Measure of Leg Sizes | CHECK PRICE |

| Automatics Fillet Weld Gauge | Fast & reliable Welding Gauge. Automatic Reading For Fillet throat size measurement | CHECK PRICE |

| Skewed Fillet Weld Gauge | Skewed Fillet Weld Gauge Stainless Steel body Suitable for Skewed Fillet Weld measurement | CHECK PRICE |

Types of Fillet Weld Gauges

Fillet weld gauges are tools used to measure the size of a fillet weld. They come in different shapes and sizes, and each type is designed for a specific purpose.

The most common type of fillet weld gauge is the direct reading fillet weld gauge, which has a calibrated scale that measures the size of the weld in millimeters or inches.

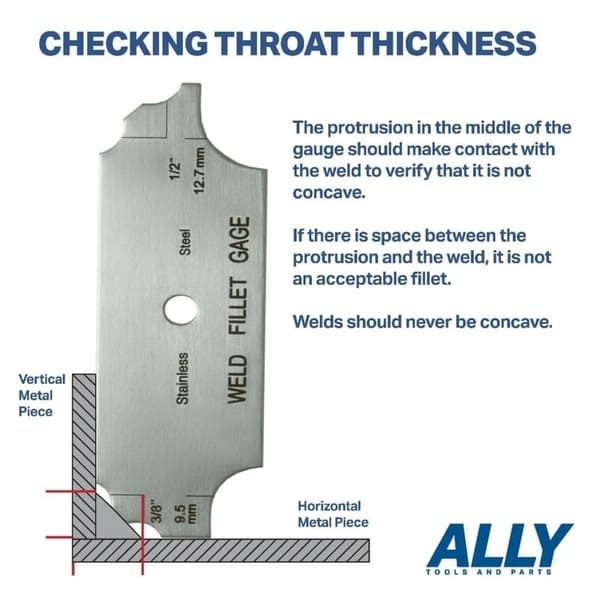

Another type of fillet weld gauge is the throat thickness gauge, which is used to measure the thickness of the fillet weld at its thinnest point i.e. weld throat. Throat thickness gauges can be used to determine whether a fillet weld is adequate for a given application & load.

The main types of Fillet weld Gauges as listed below:

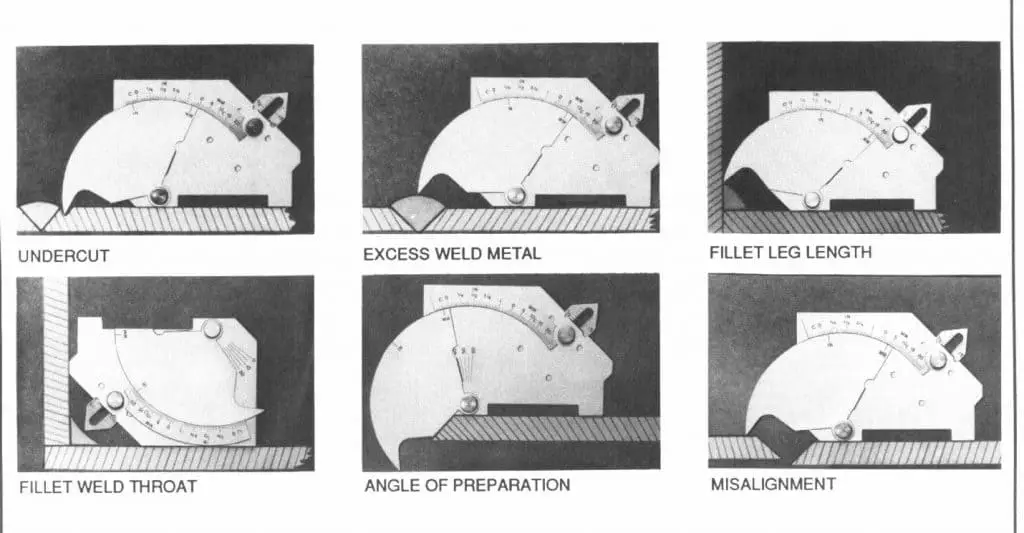

- Multipurpose Welding Gauges (E.g., Bridge Cam Gauge)

- Template type Fillet Weld Gauges (7 Pc fillet weld gauge)

- Digital Fillet weld Gauge

- Adjustable Fillet Weld Gauge

- ISO Welding Gauge

- Automatic Fillet Weld Gauge

- Skewed Fillet Weld Gauge

How to Use Fillet Weld Gauge?

A Fillet Weld Gauge, or simply Welding Gauge, is an extremely handy tool for weld Inspection.

This simple gadget allows you to measure the size of your welds quickly and easily, ensuring that they are consistent, and of the correct size as per the fabrication drawing.

When using Fillet Weld Gauge, make sure to:

- Check the Fillet Weld Gauge is in good condition.

- Fillet Weld Gauge is calibrated.

- The person know how to use it. If not, follow below guidelines.

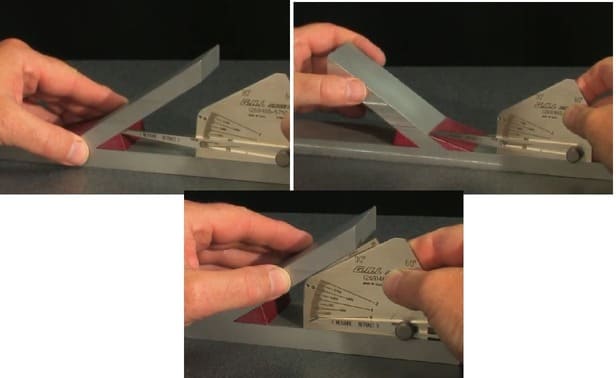

Placing the Fillet Weld Gauge

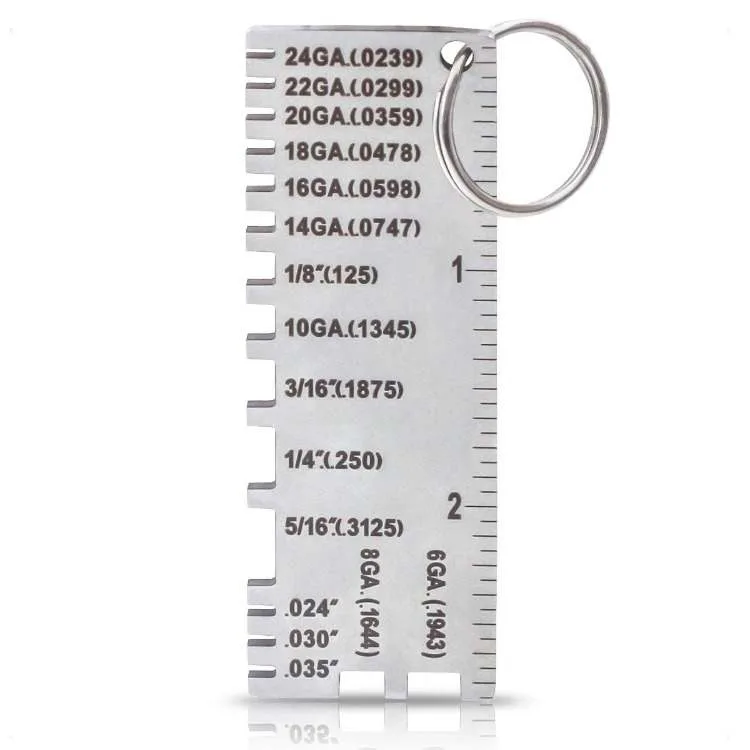

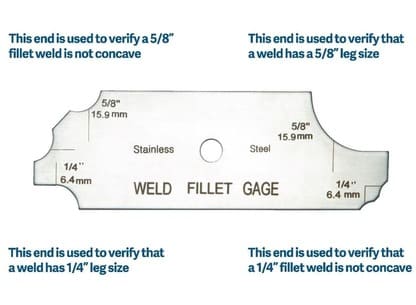

This explanation is for using the Fillet Weld Gauge Set. A fillet weld gauge set is having set of profile templates for various fillet weld sizes.

To use a fillet weld gauge set template, first select the size you would like to inspect from the gauge template based on the fabrication drawing requirements.

Visually see the type of the fillet either convex or concave type & choose the template to be used from the welding gauge as explained below.

Then place the gauge against the weld and press down until you hear a clicking sound. Make sure that both the vertical & horizontal planes of the welding gauge fit the base metal surfaces without any gap.

Reading the Weld Size on Fillet Weld Gauge

Once the Fillet Weld Gauge is at right position, check the reading directly without disturbing the gauge. This is straightforward & easy. The weld size can be ready directly on the welding gauge as shown in the above figure.

How to Measure Fillet Weld using Fillet Gauge – www.materialwelding.com

Fillet Weld Gauge Set

The most important tool for welding is the weld gauge set. This is a collection of tools used to check the size, shape and location of welds.

A weld gauge set is necessary to make sure that the welds are consistent and of the correct size.

A fillet weld gauge set is having set of profile templates for various fillet weld sizes as shown below. Below picture shows a Fillet Weld Gauge Set used for welding inspection.

Fillet weld gauges are used to measure the size of:

- a Convex Fillet Weld.

- a Concave Fillet Weld

Fillet Weld Inspection Gauges

A fillet weld is an important part of many metal structures. To ensure that these welds are strong and effective, it is important to use the proper inspection gauges. There are a variety of different gauges available, each designed for a specific type of weld.

The most common type of fillet weld inspection gauge is the types of gauges explained above. They perform linear measurement for Fillet weld sizes similar to a Vernier Caliper.

This tool can be used to measure the weld sizes such as leg length & throat size. It can also be used to measure the depth of a groove weld. Other types of inspection gauges include height gauges, radius gauges, and angle finders.

It is important to use the correct inspection gauge for each type of weld. Using the wrong gauge can lead to inaccurate measurements and poor-quality welds.

Gal Fillet Weld Gauge

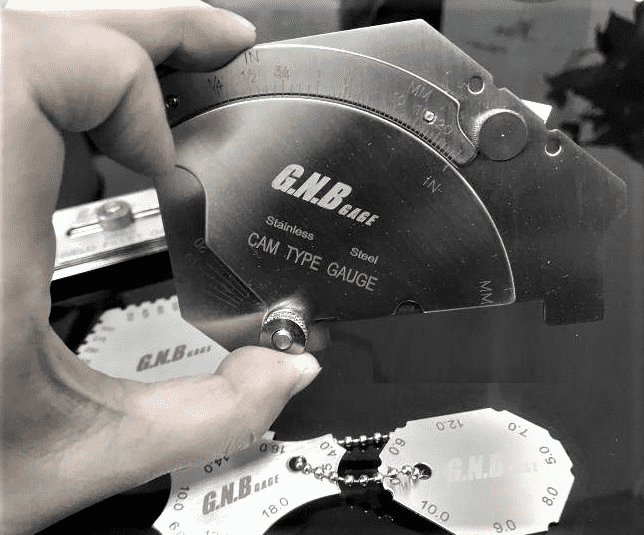

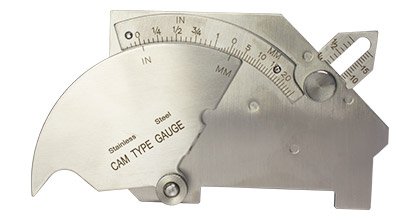

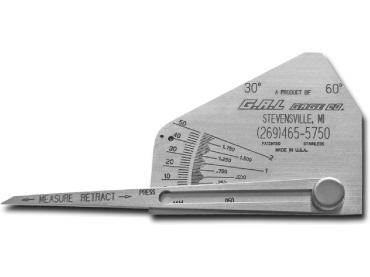

A Gal Fillet Weld Gauge or also called Bridge Cam Gauge is a tool that is used to measure the size of a weld.

It is important to use a welding gauge to verify the weld size, as it ensures that the weld is the correct size and will be strong enough to hold the pieces together.

Click below link to Learn about Bridge Cam Gauge in detail about:

- What is Gal Gauge?

- What are the uses of Gal Gauge?

- How to use it for Fillet Weld measurement?

- How to calibrate it?

bridge cam weld gauge uses, calibration

Skewed Fillet Weld Gauge

Welders use a skewed fillet weld gauge to measure the size of a fillet weld. This type of gauge is not as accurate as a straight fillet weld gauge, but it is still more accurate than measuring the size of the weld with a ruler.

The most common type of skewed fillet weld gauge is the V-notch gauge as shown in the below picture with example of measurement.

Skewed Fillet Weld Gauge can be used to measure the:

- Inside Fillet Weld of a skewed Fillet Weld

- Outside Fillet Weld of a skewed Fillet Weld

- Angle of the skewed Fillet Weld

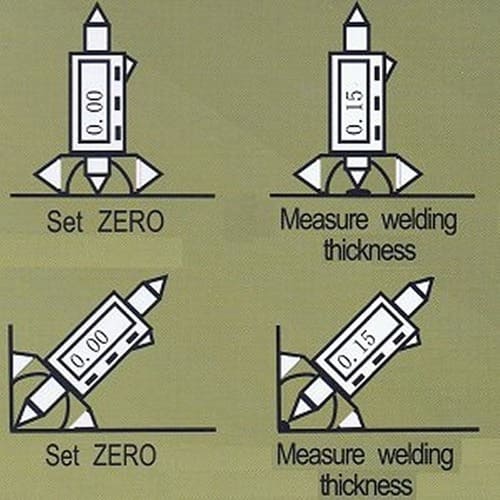

Weld Fillet Gauge Calibration

Welders & Welding Inspection (QA-QC Personnel’s) use fillet gauges to measure the size of a weld’s fillet. Fillet gauge calibration is important to ensure accuracy when measuring weld size.

The calibration process involves adjusting the gauge so that it reads zero when the fillet arm is placed in the center of the weld.

This is typically done by adjusting a set screw on the gauge. Some gauges also have a built-in Vernier scale that can be used to more accurately measure the size of a weld.

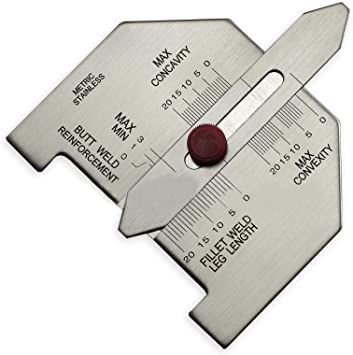

Adjustable Fillet Weld Gauge

Welders use a weld gauge to measure the size of a fillet weld. The weld gauge is a straightedge with a notch in one end and a scale along the edge.

The notch is placed against the weld, and the scale is used to measure the width of the weld.

An adjustable Fillet Weld Gauge can be used for:

- Measurement of Throat Size

- Measurement of Leg Length

Most weld gauges are adjustable, which allows them to be used for different sizes of welds. The adjusting mechanism may be a screw or a lever, which moves the straightedge up or down.

Some gauges have two notches, one for measuring the width of the root of the weld and one for measuring the width of the face of the weld.

Digital Fillet Weld Gauge

A digital fillet weld gauge is a tool that is used to measure the size of a fillet weld. The gauge is usually a small metal plate that has been machined to have a specific radius.

The plate is then placed against the weld and the size is measured with a caliper. This allows the welder or Welding Inspector to know if they are meeting the required specifications for the weld.

Fillet Weld Gauge Uses

Welders use fillet weld gauges to measure the size of a fillet weld. The gauge is placed against the weld and the distance between the two jaws is measured.

This measurement is used to check the quality of the weld and to ensure that it meets the required size specifications.

The weld size should be equal to or greater than the thickness of the base metal. If the weld is too small, it will not be strong enough to hold up under stress. Fillet Weld Gauges are used for:

- Measuring the Leg Length of Fillet Weld.

- Measuring the Fillet Weld Throat Size

- Measuring the undercut depth.

Similar Posts