What is Bridge Cam Weld Gauge?

Visual aids (magnifying glass, torch) and gauges are used to support the detection of welding discontinuities and to measure the size of welds in fabrication companies.

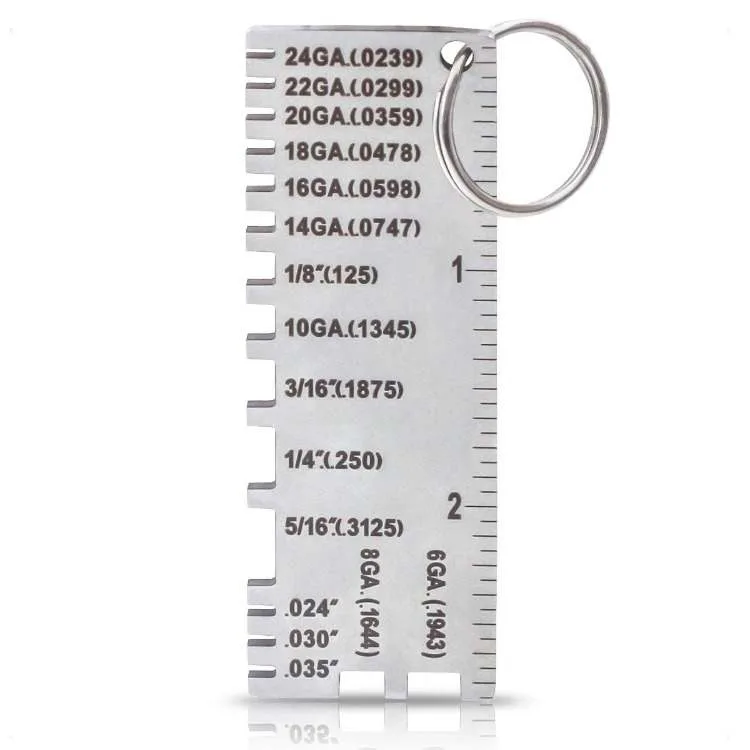

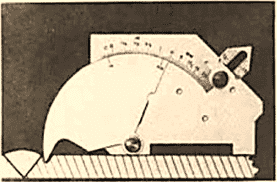

There are many different types of welding gauges used for inspection although Bridge Cam Gauge or also called Cambridge Gauge is a simple, versatile, accurate, easy to use, and handy welding gauge.

Bridge Cam Gauge is a versatile gauge as with one single gauge you can perform many tasks, such as:

- Measurement of weld bevel angle or angular measurement of any other surface.

- Measurement of Weld joint misalignment.

- Measurement of undercut depth.

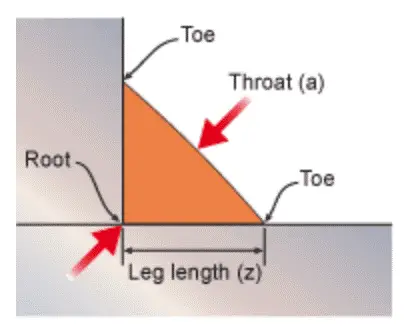

- Measurement of fillet leg length (z) and throat size (a).

- Measurement of weld reinforcement.

- Measurement of root penetration, if root is accessible.

- Linear measurement with limited dimensions.

- Measurement of pitting corrosion depth.

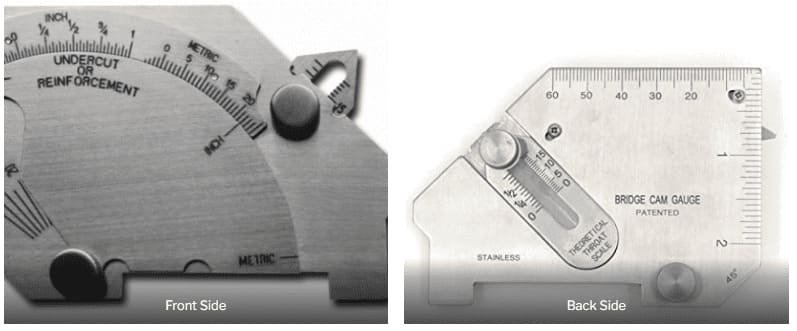

A bridge cam gauge is shown in the below picture. There are different types (such as GAL gauge) available in the market but all work in the same way.

How to use Bridge Cam Gauge

A bridge cam gauge shall be used after proper training & under competent supervision initially.

The gauge shall be secured against any damage (shock, physical damage to tip, scale, and gauge itself) so that you can rely on it’s results. As explained earlier, a Bridge Cam Gauge can be used for a number of inspections as listed above.

Below are the main uses of Bridge Cam Gauge, How to Use it for different measurements are listed with reference to pictures.

Make sure you rest the reference faces of the gauge before taking the final reading.

Ensure the tip touches the weld toe in case of a fillet size measurement, weld face height in case of weld reinforcement height check, or the deepest point of the pit or undercut, for example for an accurate and effective inspection.

Measurement of Fillet weld Leg Length size

Measuring the leg length of a Fillet weld with a bridge cam gauge is easy and fast. The gauge is placed on one member, allowing both resting areas of the gauge on the plate.

The gauge tip is adjusted according to the height of the leg length and the leg length size will be found on the angular scale as shown in below figure either in inches or millimeters.

Measurement of Weld Reinforcement Height

Weld reinforcement or weld face of weld root penetration height measurement using bridge cam gauge is shown in the below example.

The measurement is similar to measuring the leg length of the fillet weld as explained above.

Measurement of Fillet Weld Throat Size

For measuring the throat size of a fillet weld using a bridge cam gauge, you need to use the attachment on the backside of the gauge.

For measurement, rest both faces of the gauge on both weld joint members firmly.

Now, adjust the measurement scale on the face of the throat and you will find the throat size on the backside scale in either inches or millimeters, as you wish.

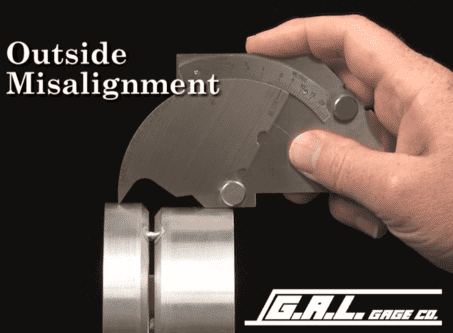

Measurement of weld joint Misalignment

Bridge cam gauge is also used to measure weld joint misalignment, In fact, this is the best gauge for misalignment inspection.

The gauge is placed on the one side of the joint, which is on the lower plane and the tip is touched on the plate on the higher plane. The misalignment is read on the angular scale as shown in the below picture.

Measurement of Bevel Angle or Angular dimension

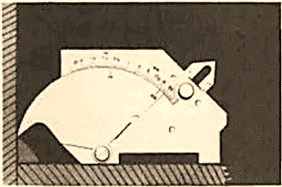

Measurements of the bevel angle or angle of weld preparation are shown in the below figure.

Measurement of Undercut

Measurements of the undercut is shown in the below figure. The tip is touched to the undercut or pit depth and size is found in the angular scale.

Calibration of Bridge Cam Gauge

Welding gauge calibration is an important part of welding Quality Control & Assurance. It ensures that the welds meet the minimum weld size requirements & meet the required specifications.

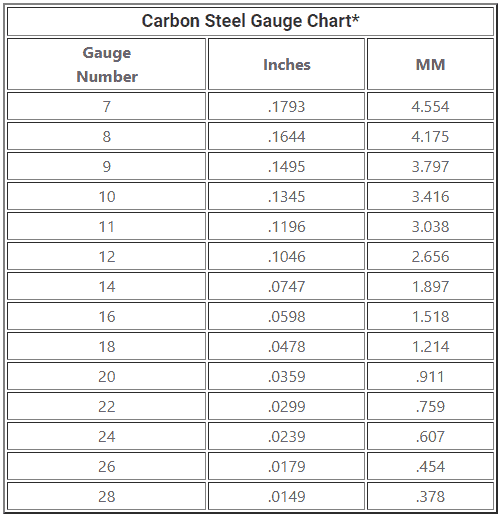

Welders & Welding Inspectors use welding gauges to measure the weld size and to make sure that they are within the acceptance limit.

If the weld is not within specification, it will not meet the strength requirements, which could lead to a failure in the weld.

Calibration of bridge cam gauge shall be made using the calibration block. It’s always advisable to calibrate the welding gauges with the manufacturers.

For example, for the Bridge Cam gauge from Gal Gage, it’s good to use their calibration services. The calibration is carried out for:

- Any visible wear and tear.

- Linear and angular scales.

- Verification of measurement tips.

Welding gauge calibration should be done on a regular basis, preferably every 6 months frequency tor when there are visible damages to the gauge. This will ensure the welding gauges are in the proper state & conditions.

Similar Posts