Weld Quality: Visual Inspection of Welds

Visual Inspection or Visual Testing (VT) of Welds is a inspection method where welds external are checked for acceptability against a defined minimum quality acceptance criteria. Hence, the most important factor for weld quality inspection is the acceptance criteria.

The acceptance criteria will vary depending on the application (Structure welding or pressure vessel or piping, for example) and the governing code or standard. Other factors to consider when performing a visual inspection of welds include: Welding process, base material, filler material, and joint design.

When checking welds for acceptability, the Welding Inspector must have a clear understanding of the acceptance criteria. If the acceptance criteria are not met, then the weld must be rejected. The most common reason for rejection is the presence of Welding Defects such as welding Crack, Lack of Fusion, porosity, slag inclusion, incomplete root penetration, and excessive reinforcement, etc.

What is Visual Inspection in Welding?

Visual Inspection is a process of examining welds to evaluate their quality & acceptance according to acceptance criteria, and is an important part of welding quality control.

In general, visual inspection of weld includes an examination of the weld bead profile, width and penetration (where applicable), as well as any defects that may be present in the welding and Heat Affected Zone (HAZ).

Welds are also checked for proper alignment, dimensions as per drawing and spacing at three stages:

- Before Welding: inspection of base metal, welding electrodes & equipment’s, review drawings.

- During Welding: in process welding inspection to validate compliance of welding procedures, check weld root and preheat & interpass temperature.

- After Welding: Final weld visual inspection.

If any welding defects are found during visual inspection, they required to be repaired before finally accepting the welded part by the welding inspector. This will help to ensure that the final product meets all the required welding quality standards.

Weld Quality Standards

Weld quality standards are set by various organizations including the American Welding Society (AWS), the American Society of Mechanical Engineers (ASME), Canadian Standards Association (CSA) and the International Organization for Standardization (ISO).

The AWS D1.1 standard is widely used in the construction industry in the USA and around the world, while the ASME B31.3 standard is commonly used in the piping jobs for petrochemical and oil & gas industries. The ISO 5817 standard is used in a variety of industries, such as welded parts, shipbuilding and offshore construction.

The ASME Section IX welding code is another important welding quality standard. It provides requirements for welders and welding procedures, as well as nondestructive testing methods. These standards help ensure that welds are properly made and meet the required strength and integrity levels.

A summary of Welding Quality Standards are:

- AWS D1.1: Structural Welding Code- Steel

- ASME B31.3: Process Piping Code

- ASME Section IX: Welding and Brazing Qualifications Code

- API 1104: Welding of Pipelines

- ASME Section VIII: Pressure vessel construction rule

- CSA W59: Welded Steel Construction

- CSA W59.2: Welded Aluminum Construction

- CSA W186: Welding of Rebar

- BS EN ISO 5817: Fusion welding joints in steel, nickel, aluminum: Quality Level of Imperfections

- DIN EN ISO 6520-2: classification if geometric imperfections in metallic materials welding with pressure

- ISO 6520-1: Geometrical imperfections in metallic materials: Fusion Welding

- ISO 10042: Welding – Arc-welded joints in aluminum and its alloys – Quality levels for imperfections

- ISO 17637: Non- destructive testing of welds – Visual testing of Fusion welded joints

- AWS B1.11: Guide for Visual Inspection of Welds

Welding Visual Inspection Standard

Welding is a critical process in the fabrication of metal structures and components. The quality of the welds is essential to the safety and integrity of the finished product. Below are the main Welding Visual Inspection Standards and Code with respective reference for Acceptance Criteria:

- AWS D1.1: Visual Inspection acceptance criteria given in Table 8.1, page 239 in 2020 Ed.

- ASME B31.3: Visual Inspection Acceptance Criteria for Welds is given in Table 341.3.2.

- API 1104: Acceptance criteria given in Clause 8: Inspection & Testing of Welds.

- ISO 5817: Acceptance criteria given in Table 1 for all type of welding defects.

- ASME Section IX: Acceptance criteria given in clause QW:194.

The welding visual inspection standard that is most commonly used in the United States is AWS D1.1. This standard covers the requirements for welding steel structures, such as bridges and buildings. It includes specifications for joint design, welding processes, welding consumables, and inspection methods.

ASME B31.3 is another widely used welding visual inspection standard. It covers the requirements for piping systems that are used in petroleum refineries, chemical plants, and other industrial facilities.

Welding Visual Inspection Acceptance Criteria

To ensure the quality of a welding procedure, final weld need to meet the Acceptance Criteria defined in the applicable code or standard during the welding inspection by Welding Inspectors. These weld visual inspection criteria is based on:

- Inspection & verify the weld size (throat size or Leg Size or fillet weld) and dimensions.

- Acceptable weld bead profile having good workmanship.

- Weld free from welding defects or within the limit as per acceptance criteria.

- Verify dimensional accuracy of weld.

If any of these criteria are not met, it may result in a weld that is not strong enough and could fail during service or just after welding. This could lead to serious consequences, such as personal injury or damage to equipment & financial losses. That is why it is so important to have well-defined Acceptance Criteria for welding visual inspection.

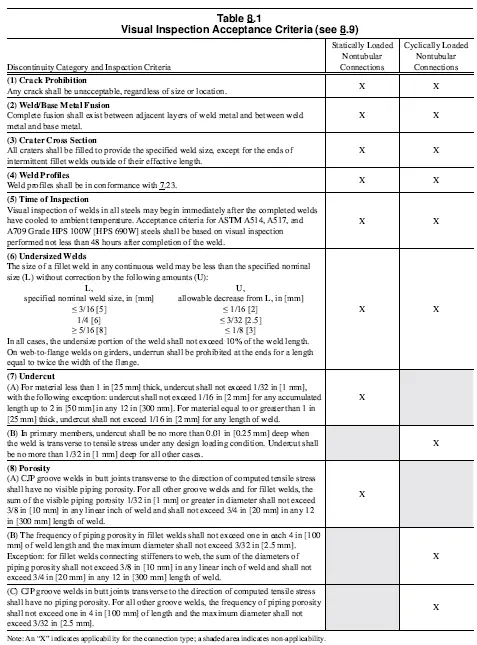

Visual Weld Inspection Acceptance Criteria AWS d1.1

Weld visual inspection criteria is given in AWS D1.1 Clause 8: Inspection. Table 8.1 covers the welding acceptance criteria for cracks, lack of weld fusion, weld profile, undercut, porosity and undersize welds. An abstract of AWS D1.1 Table 8.1 & 101.15 (for Tubular connections) is given below for reference.

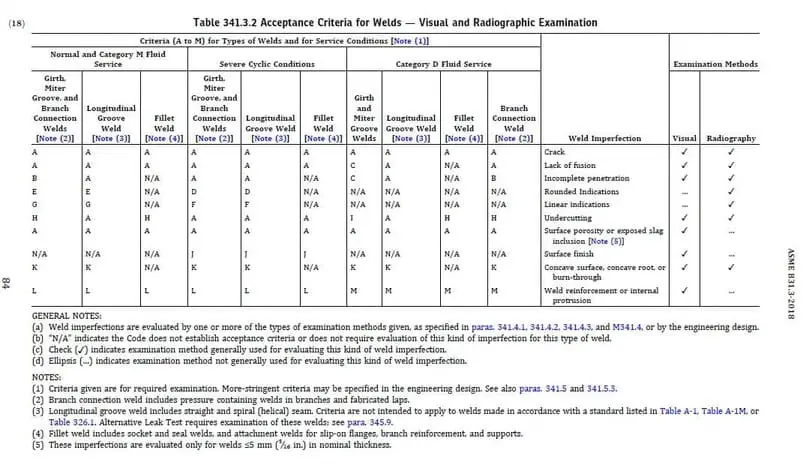

Visual Weld Inspection Acceptance Criteria ASME B31.3

In ASME B31.2, acceptance criteria for weld visual inspection is given for cracks, lack of fusion, porosity, undercut, surface finish, incomplete penetration, etc. in Table 431.3.2 given below for reference.

Based on the service conditions, weld defect acceptance is categorized from ‘A to M’ in Table 341.3.2, page 2 with their acceptable limit values.

Visual Weld Inspection Acceptance Criteria ASME Section IX

Weld visual inspection criteria for welder qualification and procedure qualification is defined in ASME Section IX- QW194. According to QW 194, the weld shall be free from cracks, lack of weld fusion and show complete joint penetration.

The welding visual quality level given in ASME Section IX is not detailed like AWS D1.1 or ASME B31.3 or ISO 5817 but instead a general conditions stated.

Weld Visual Inspection Checklist

A weld visual inspection checklist is a document used by inspectors to ensure that all welding meets the required standards. The checklist includes a list of all the welding requirements and specifications that need to be met.

You can download sample weld visual inspection checklist from this link.

Weld Visual Inspection Procedure

Preparing the weld surface area for inspection is important because it allows the inspector to get a clear view of the weld. The first step is to remove any debris or contaminants that might be present and can hamper the clear view of welding area.

Next, the inspector will use a measuring device to take accurate measurements of the weld. Finally, the inspector will take photographs of the weld area from different angles.

Performing the actual inspection is crucial to ensuring that the weld meets all quality standards. The inspector will closely examine the weld for any defects such as cracks, porosity, or incomplete fusion.

Related reading: How to Use Fillet Weld Gauges?

A weld visual inspection is conducted to ensure that the welds made meet the required standards. The inspector will look for any defects on the surface of the weld or in the structure of the weld itself. There are three main steps in a weld visual inspection:

- The first step is to review and get familiar with the welding drawing, acceptance criteria and know what type of welding check will be applicable & what inspection coverage is required.

- Ensure all inspection tools are in good condition and calibrated.

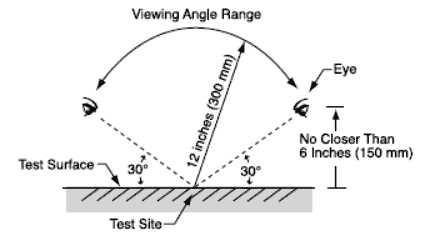

- Check the surface of the weld for any defects using right visible light intensity (recommended minimum 550Lux as per ISO 17637). This includes looking for cracks, porosity, or other flaws.

- Check the structure of the weld itself. Look for any material or other structural defects.

- Next, check for dimensional accuracy. This includes checking that the dimensions of the weld meet the requirements specified in the drawings or specifications.

- Record all observations and any non-compliance shall be reported via visual inspection report.

Tips for Successful Professional Inspections

Before getting started on your inspection assignment reflect on the following:

• Tools required (gauges, tape, ruler, magnifying glass, etc.)

• Job specifications, standards, drawings, inspection/testing plan.

• Information on the working environment safety issues, history of the company’s past performance and its cooperation; communication channel and people involved.

- Your expectations for this inspection assignment.

- Should any disagreements or arguments occur regarding your findings, how are you going to conduct yourself?

- As a professional you should have a debriefing session with those concerned before your departure, and you should leave on professional and positive terms.

How to Check Weld Visual Inspection?

When it comes to weld visual inspection, there are a few key things you need to keep in mind. First and foremost, you need to make sure that you have the right tools for the job.

Follow the steps covered under Weld Visual Inspection Procedure.

Weld Visual Inspection Report Format and Sample

A weld Visual report format is important part of weld quality documentation. A complete weld visual inspection report should contain:

- Job details- Name, Number

- Description

- Quantity

- Acceptance code/ standard/ specification

- Light intensity

- surface conditions

- Stage of welding inspection

- Material details

- Sketch if required.

- Signed by welding inspector & date of report

Click here to download sample Weld Visual Inspection report format.pdf

Welding Defects Visual Inspection

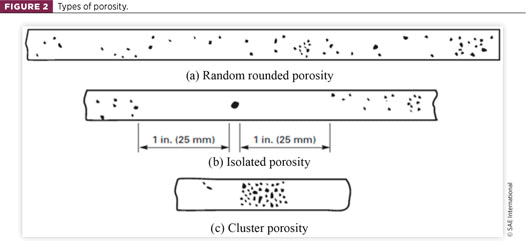

There are several different types of welding defects that can be identified during a visual inspection. These defects include incomplete fusion, porosity, cracking, and slag inclusion. Incomplete fusion occurs when the weld metal does not properly adhere to the base metal. Porosity is caused by gas pockets that are present in the weld metal.

Related Reading: Welding Undercut- causes & Remedies

Cracking can occur in the weld metal or heat-affected zone due to thermal stress or impurities in the base metal. Slag inclusion occurs when bits of slag become trapped in the weld metal.