Lack of Fusion in Welding

Welders use various techniques to make sure the welds they produce are strong and free of defects. One common defect is lack of fusion, which can be caused by a number of factors, such as incorrect welding parameters or contamination on the weld surface.

This article provides tips on What is Lack of Fusion, Its types & causes, how to check for lack of fusion in welding and How to prevent it?

Lack of Fusion in Welding or LOF or Cold Lapping is a Welding defect. During welding, the weld fusion is the joining of two pieces of metal by heating the surfaces to a temperature where the metal liquefies and then fuses together.

For a strong weld & excellent mechanical as well as technological properties, the weld fusion should be complete, with no gaps or porosity present between the weld metal and base metal.

Due to various conditions, a welding defect can arise where there is insufficient fusion between the base metal weld face and the weld metal.

This welding defect is known as Lack of Fusion or Cold shut or Cold Lapping. Lack of fusion is also called Lack of continuity in Welding.

Lack of fusion is not a crack but the severity of Lack of fusion defect is similar to the Crack. Both crack and Lack of fusion reduce the welding strength in a similar way & prone to propagation under loading, especially dynamic loading conditions.

What Causes Lack of Fusion in Welding?

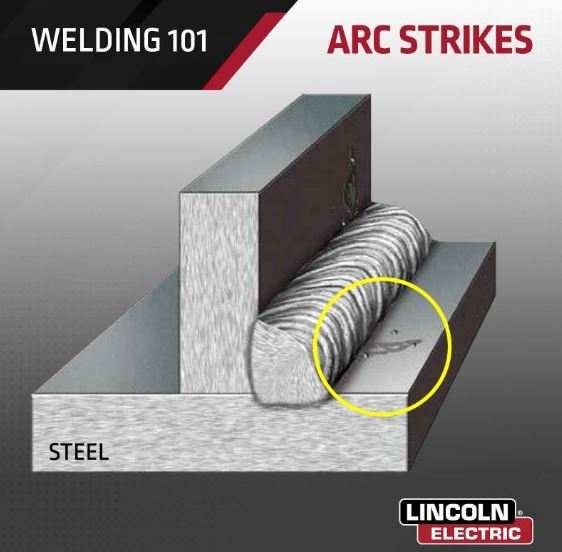

Lack of weld fusion can be caused by several factors, including:

- Incorrect welding parameters- if the heat input is too low, the weld will not fuse properly.

- Mode of Metal Transfer- Metal transfer mode that gives low heat input can cause Lack of fusion. Such as short circuit transfer mode in GMAW.

- Incorrect welding technique- if the welder does not hold the electrode steady and in the correct position, it can cause lack of weld fusion.

- Poor fit-up- between the two pieces of metal can also lead to lack of weld fusion. A large gap in weld joint fit-up will not provide direct arc to the base metal weld surface & can result in LOF.

- Incorrect weld bevel preparation- An insufficient weld bevel angle, or uneven weld surface preparation of the weld joint can also be the cause of lack of fusion.

- Insufficient cleaning of base metal- Base metal that has scale or rust can prevent the fusion between the weld metal and base metal. This will also result in lack of fusion.

Lack of weld fusion can cause a number of problems, including reduced strength and decreased corrosion resistance. LOF present in the weld will result in reduced notch strength of the weld metal.

What is Lack of Fusion in Welding?

Welders are often tasked with joining two pieces of metal together. This is done by heating the metal until it is molten and then using a welding rod to join the two pieces together. The weld will be strong if the two pieces are fused together properly.

However, if there is a lack of fusion, the weld will be weak and may fail. There are several factors that can cause a lack of fusion, including poor welding technique, dirty or rusty metal, and incorrect welding settings as explained in detail earlier.

If you notice a lack of fusion in your welds, you should take steps to correct the problem before continuing with the weld.

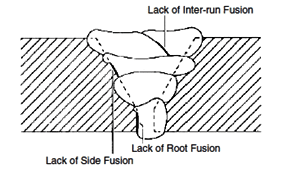

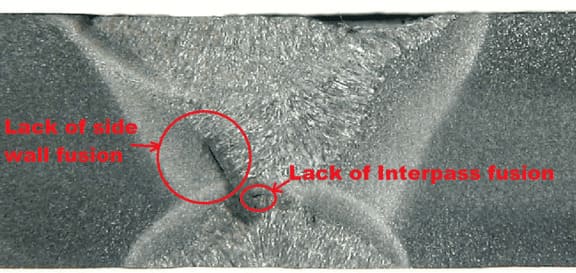

Lack of fusion (LOF) can occur in welding at different areas such as:

- Lack of interpass fusion

- Lack of sidewall fusion

- Lack of root fusion

- Lack of capping bead fusion, known as overlap in welding.

What is Lack of Interpass Fusion in Welding?

Lack of interpass fusion (LIF) is a welding defect that can occur during welding between weld passes. It is caused by the failure of two weld beads to fuse together, resulting in a visible separation between the two.

This can lead to a decrease in the overall strength and stability of the weld, and may require corrective action before the weld can be considered finished or accepted finally.

Most of Interpass Lack of Fusion are internal weld defects & they can be detected only by:

- Volumetric NDT such as UR or RT.

- Destructive test such as Macro or bend test.

There are several factors that can contribute to Lack of interpass fusion or LIF, including incorrect welding technique & torch angle, insufficient cleaning between weld passes, incorrect filler material choice, or an unsuitable welding environment. It is important to understand the causes of LIF so that it can be avoided during the welding process.

What is Lack of Sidewall Fusion in Welding?

Lack of sidewall fusion is an imperfection found on the sidewall of a weld joint. In Lack of Sidewall fusion, welding beads does not fuse the weld face of the base metal. This result in separation between weld and weld face.

What is Lack of Root Fusion in Welding?

Lack of root fusion is a welding defect that can occur when the weld metal does not fuse the root face of the base metal at the weld joint. This can cause a weak point in the weld, which may lead to failure.

Lack of root fusion may be caused by several factors, including poor weld preparation, incorrect welding technique, or incorrect welding parameters. It can also be caused by contamination of the weld joint surface.

There are several ways to prevent or correct lack of root fusion. The most important step is to ensure good weld preparation, including proper cleaning and surface preparation.

Welders should use the correct welding techniques and parameters, and must ensure that the welding equipment is properly calibrated.

Contamination of the weld joint surface can be prevented by using clean materials and adequate shielding gas coverage.

How to fix & Prevent a Lack of Fusion in Welding?

Welders often face the problem of a lack of fusion. This can be caused by many factors, such as incorrect welding technique, incorrect welding parameters, or improper preparation of the weld joint. In some cases, a lack of fusion can be fixed by adjusting the welding parameters.

If the weld joint is not clean and free of contaminants, it may be necessary to clean it before welding.

If the weld puddle is too large, it may be necessary to reduce the welding current. If the weld bead is too small, it may be necessary to increase the welding current.

In other cases, a lack of fusion cannot be fixed by adjusting the welding parameters. In these cases, it may be necessary to use a different welding process or to use a different type of filler metal.

How to Check Lack of Fusion in Welding?

Welding is an essential process in many industries, but if the welds are not performed correctly, they can lead to a number of problems.

One such problem is lack of fusion, which can occur when the weld metal does not fuse properly with the base metal. This can cause the weld to be weak and susceptible to failure.

Lack of fusion are linear indication having similar characteristics like a welding crack and are very detrimental. They reduce the welding joint strength drastically especially for dynamic or cyclic loading application.

There are several ways to check for lack of fusion in welding. Radiographic testing (RT) and ultrasonic testing (UT) are two common Non- Destructive Testing methods that can be used to detect this type of defect.

RT involves using X-rays or other radiation to create images of the weld, while UT uses sound waves to create images of the weld. These images can help identify any areas where the weld metal has not fused properly with the base metal.

If lack of fusion is detected, it needs to be corrected immediately.

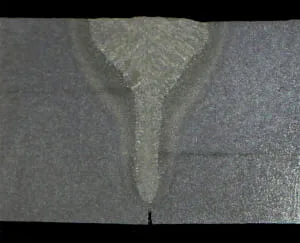

How Lack of Fusion appears on a Radiographic Film?

Lack of fusion can often be seen on a radiographic film as a dark linear spot in the weld. Lack of fusion reduces the weld density in the affected area and thus it results a dark line or spot on the RT film based on the intensity of the lack of fusion defect in the weld.

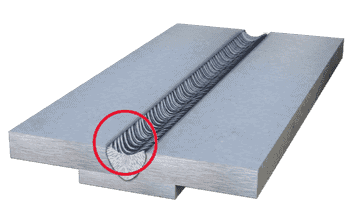

Depth of Fusion in Welding

Depth of Fusion or Depth of Penetration in welding is the depth to which the weld pool is able to penetrate the base material.

Penetration is important because it ensures that the weld is strong and that there are no gaps or porosity in the weld joint.

A good depth of fusion welding results in a sound, strong weld. Weld penetration can be affected by a number of factors, including the type of welding process used, the composition of the base material, and the welding parameters.

Welding processes that use an electrode (stick welding, MIG welding, TIG welding) typically have better penetration than those that use a flux-cored wire (FCAW welding). The reason for this is that with an electrode, you are actually have more arcing force.

Fusion face weld

Fusion Face in a welding means the surface that get fused during the welding & create a joint between the weld metal and base metal. In a V-groove Joint, the taper surface of the welding joint represent the weld face.

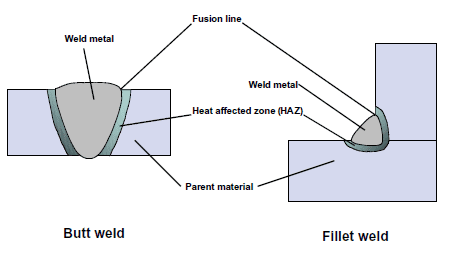

Fusion line in welding

Welding is the process of joining two pieces of metal together by heating them to a temperature where they will fuse together.

The welding process creates a heat affected zone (HAZ) around the weld. The HAZ can be very difficult to weld and may require special techniques or equipment.

The fusion line in welding is the line where the two pieces of metal are joined together. The fusion line is usually very smooth and free of defects.

The HAZ is located on either side of the fusion line. Fusion Line in Welding can be seen on a welding macro sample that differentiate between the weld metal and Heat affected zone.

Learn about other welding defects:

- Welding Porosity.

- Undercut in Welding.

- Overlap in Welding.

- Welding Spatters.

- Tungsten inclusion in welding.

- Welding defects, their causes and remedies.

- Types of Crack in welding and crack prevention

Similar Posts: