Lack of fusion and lack of penetration are both welding defects that can occur during the welding process. Lack of fusion primarily affects the integrity of the joint, while lack of penetration primarily affects the load-bearing capacity of the joint.

What is Lack of Fusion?

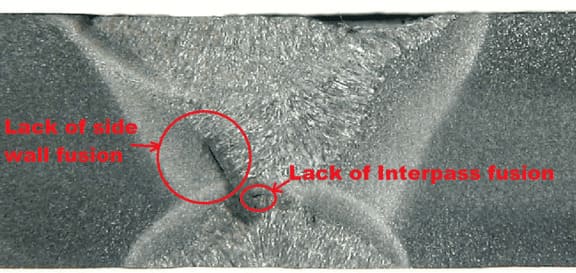

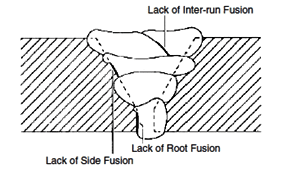

Lack of fusion (also called LOF or incomplete fusion) occurs at weld metal (WM) or weld interface (WI) when the weld metal fails to fuse completely with the base metal or with the previous layer of weld metal. This can result in a weak joint that is prone to failure under stress or load similar to slag inclusion or porosity, if it is continuous.

Lack of fusion can occur in all of fusion welding & solid-state welding processes and in fillet, groove or other types of weld. Lack of fusion is an internal welding defect (weld overlap that occurs on weld face is similar to lack of fusion, but it occurs as final weld pass where base metal doesn’t fuse with weld metal).

Read more in depth: Lack of Fusion in Welding-Causes-Remedies

LOF can be due:

- Process & procedure failure (e.g., wrong welding parameters, electrode angle),

- Metallurgical issues (lack of metallurgical solubility between two metals),

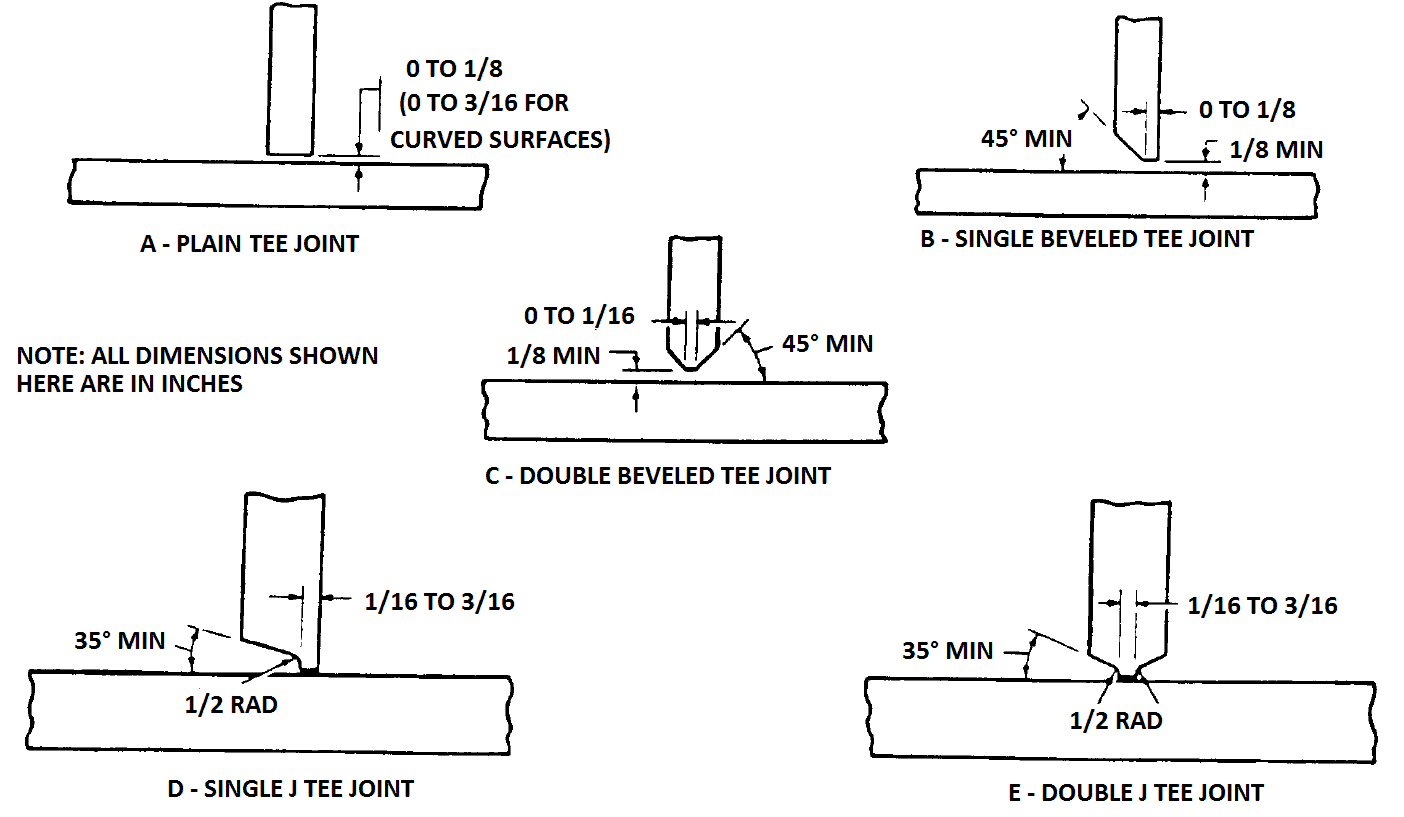

- Design issues (inadequate groove angle).

Lack of fusion or incomplete fusion can be intermittent or throughout (continuous) the length. It can be major LOF or minor LOF too.

What is Lack of Penetration?

Lack of penetration (also called as LOP or incomplete penetration), on the other hand, occurs in weld metal (WM) when the weld metal fails to penetrate through the full thickness of the base metal. This can result in a joint that is not strong enough to support the intended load or is prone to cracking.

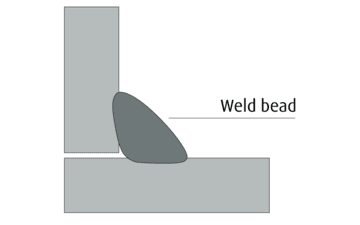

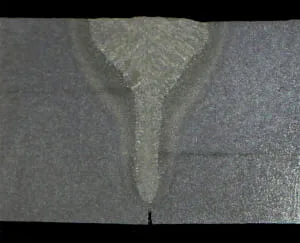

Below are two example of incomplete penetration in Fillet and groove weld joints.

Lack of penetration (LOP) is found mainly in groove weld joints as well as Fillet welds at root location where weld metal doesn’t extend or penetrate through the base metal thickness. This is a major concern when joint configuration is Complete Joint Penetration (CJP).

API 1104 standards for pipeline call LOP as Inadequate penetration and further classified as:

- Inadequate penetration without high-low.

- Inadequate penetration due to high-low.

- Inadequate Cross penetration.

Lack of Fusion vs Lack of Penetration

| Defect | Lack of Fusion | Lack of Penetration |

|---|---|---|

| Description | Incomplete fusion between weld metal and base metal | Incomplete penetration of weld metal through joint |

| Causes | Insufficient heat input, wrong welding angle, improper joint preparation, poor welding technique | Insufficient heat input, wrong welding angle, improper joint preparation, poor welding technique, incorrect weld size |

| Impact on Joint | Reduced joint strength, potential for premature failure | Reduced joint strength, potential for premature failure |

| Identification | Visual inspection, radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), or dye penetrant testing (PT) | Visual inspection, radiographic testing (RT), ultrasonic testing (UT) |

| Prevention Measures | Proper joint preparation, correct welding parameters, appropriate welding technique, preheating (if necessary) | Proper joint preparation, correct welding parameters, appropriate welding technique, ensuring adequate weld size |

| Remediation | Remove the defect by grinding, then reweld using proper techniques and parameters | Remove the defect by grinding, then reweld using proper techniques and parameters to ensure full penetration |