Stress Relief in Welding

Stress relief in welding is a post-weld heat treatment (PWHT) process used to relieve the residual stresses produces by rapid cooling after welding in the welded component.

Welding is a process that can often create high levels of stress in the welded part. This is due to the fact that during welding, the part is heated to a high temperature and then cooled rapidly. This can create stresses in the part that can lead to cracking or other problems.

One way to relieve these stresses is to use a controlled cooling process in the furnace. This involves controlled heating & cooling of the welded part to a particular temperature and then holding it at this temperature for a specific amount of time, called Hold time.

Read more: Post Weld Heat Treatment or PWHT

Why Stress Relief Heat Treatment (PWHT) is required?

PWHT is an important process for ensuring the quality of welded joints, and can help to improve the performance and lifespan of the finished product. In many cases, it can also be used to prevent cracking and other issues that can occur due to high levels of stress in the material.

Stress relief heat treatment is a process where the metal is heated to a specific temperature and then cooled at a controlled rate. It is commonly used on parts that are prone to stress cracking or distortion.

Stress Relief Heat Treatment is used to:

- Improve ductility,

- Relieve internal stresses,

- Relieve residual stresses and

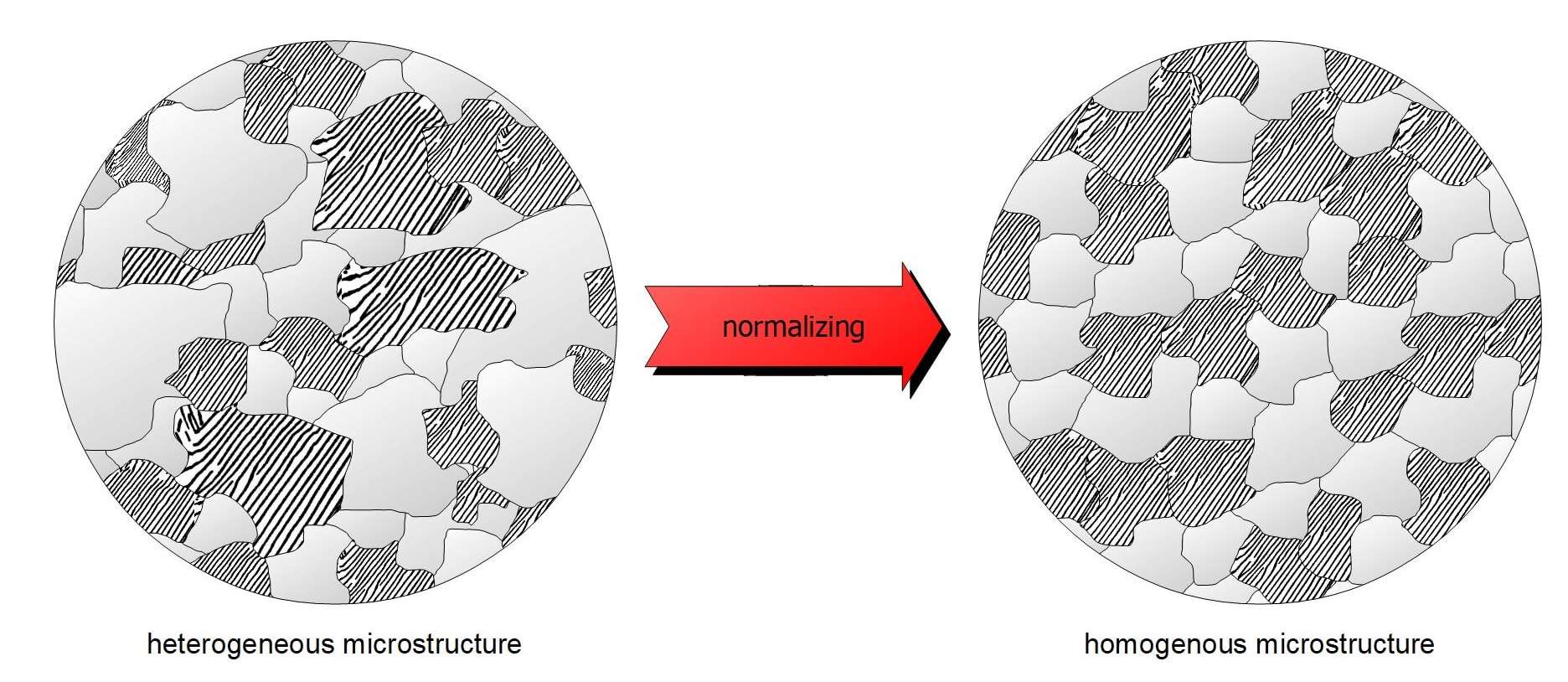

- Refine the grain structure of metals.

- Prevent dimensional changes in metals.

- Improve the fatigue resistance of metals

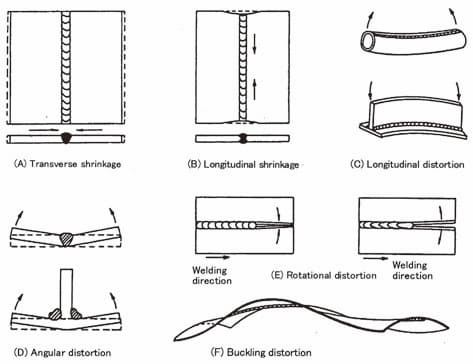

One of the benefits of stress relief heat treatment is that it can help prevent dimensional changes in metals. When metals are heated, they expand and when cooled, they contract.

This thermal expansion and contraction can cause parts to warp or distort. By relieving the internal stresses in metals, we can help minimize these dimensional changes.

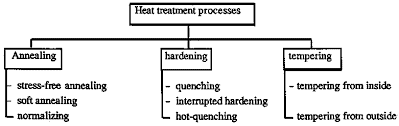

Methods for Stress Relief in Welding

There are several methods that can be used to stress-relieve a welded part (Stress Relief in Welding). The three most common methods for Stress Relief in Welding are:

- Stress Relief by heat treatment is also called SR Heat Treatment,

- Shot peening, and

- Vibration Stress Relief, also known as VSR.

1. Stress Relief by heat treatment

The best method to relieve stresses is to anneal the weldments. Unfortunately, this can only be accomplished in furnaces which normally can hardly accommodate welded components/structures of any consequence.

Stress relieving treatment, therefore, is obligatory only for essential articles, such as boiler drums and high-pressure vessels. In some cases, this heat treatment may result in warping.

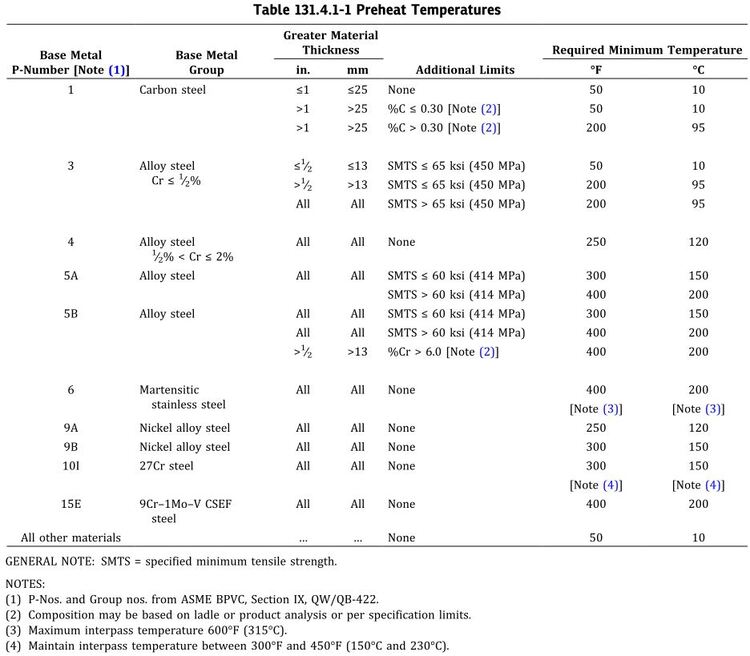

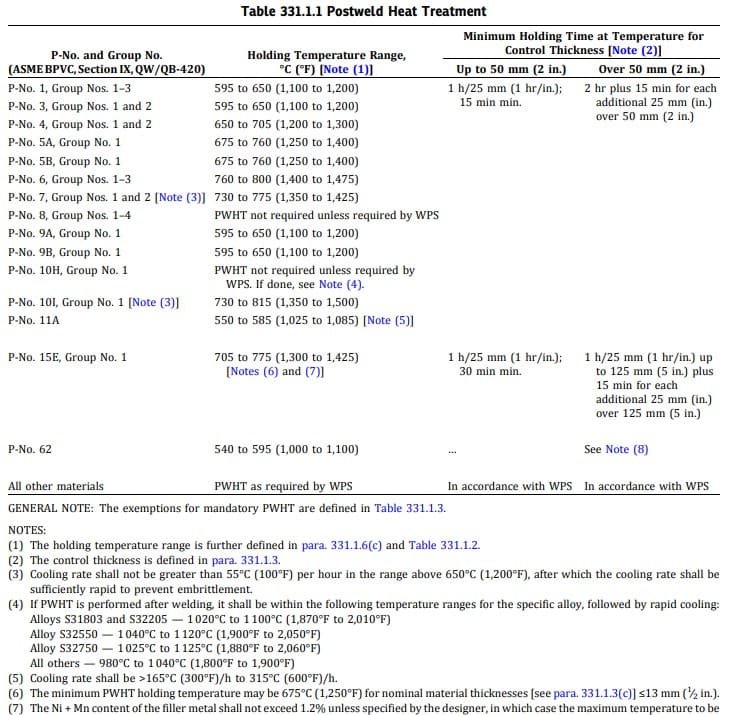

Stress relief treatment that is often given to welded components is dependent upon its material composition. The table below lists the temperature ranges used for stress-relieving post-weld heat treatment of various types of materials. (Reference ASME B31.3, Table 331.1.1).

The energy for PWHT may be provided by oil, propane or natural gas or electricity. The heat may be applied locally, or the welded components may be completely enclosed in a furnace.

PWHT temperatures, usually in the range of 540 to 815°C reduce internal stresses and help to soften hardened areas in the HAZ. The work is heated to a given temperature held at the selected temperature for an appropriate soaking time and then allowed to cool, both heating and cooling being subjected to a controlled temperature gradient such as 100-200°C per hour for thickness up to 25 mm and slower rates for thicker plates, depending upon the code being followed.

Localized heat can be applied using flexible insulated pads and finger electrical heaters. These are available in a variety of shapes with the elements insulated with ceramic beads and supplied from the welding power source or an auxiliary transformer at 60-80 volts. The pads are connected in parallel as required and are covered over with insulating material to conserve heat.

2. Stress Relieving by Shot peening

Shot peening is a process that can be used to relieve stress in metals. It involves firing small shots at the metal surface. This process can increase the fatigue life of the metal by up to three times. It can also be used to improve the performance of welded joints.

The impact of the metal balls creates tiny indentations on the surface of the metal object. These indentations help to relieve stress on the metal object and make it stronger.

Shot peening is an effective way to relieve stress on metal objects. The process is simple and does not require much equipment. It is also relatively inexpensive.

Read more: Shot Peening Method: Complete Guide.

3. Stress Relieving by Vibration Stress Relief

Vibratory stress relieving (VSR) is a resonance-based method of relieving residual stress and stabilizing metals. This is a non-thermal method, therefore there is no distortion or change of tensile strength.

Read more: Vibratory stress relieving Treatment.

Energy is introduced to the component, to be stress relieved, by means of low frequency (10 to 220 cycles/ second), and high amplitude vibrations, and can be successfully applied to parts weighing from kg to equipment weighing up to 150 tons.

For welded fabrications, stress relieving can be performed during welding which is very helpful in preventing residual stress build-up that can cause weld cracking or distortion of some sections.

Reference: ASME B31.3, API 582.