What is Peening?

Peening refers to the gently hammering the weld and/or the heat affected zone & nearby weld so that the stresses get relieved. The targeted stresses are the residual stresses generated by the welding. It should preferably be done with a pneumatic tool of moderate force.

An alternate, it may be carried out with a peening hammer of about 1 pound weight, while the weld is still hot or immediately after the weld cooled down to room temperature. In fact, peening should be done when the weld metal is at a temperature either higher than 842°F (450°C) because in the intervening temperature range it tends to crack due to reduced ductility.

Following points should be considered before peening:

- work hardening effects should be considered before peening austenitic stainless steel (300 series).

- AISI 400 series steel have relatively poor notch toughness in as-welded condition.Therefore, utmost care should be taken if peening is performed.

- Metal adjacent to the welds is usually peened as well as the weld itself.

Ultrasonic peening

The Ultrasonic Peening (UP) is a cold-working surface treatment process for fatigue life improvement of welded parts. It is called called utrasonic treatment or simply peening sometimes. The main objective of the ultrasonic peening is the release of the residual stresses generated by thermal effect of the welding process.

During peening operation, compressive stresses are induced into the weld and base metal and these compressive stresses bring the balance against the residual tensile stresses. Peening is highly benefical to reduce the stress concentration at the notch points in a welding joint thus enhance the fatigue life of the welding component.

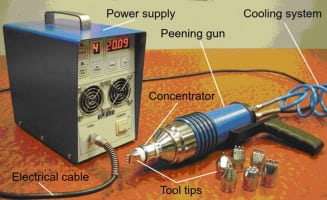

The method is carried out using specially made tool that transfer the ultrasonic energy as a compressive stress in the area of intetest and enchance mechanical properties. Basically, peening is a process to improve the fatigue life of welded part, thus provide the structural intergrity.

Ultrasonic Peening of Welds

The Ultrasonic Peening method relies on the accumulated influence of the high frequency repeated compressive stresses to eliminate the weld residual stresses and their concentration.

The method can be efficiently used for fatigue life enhancement for new welding, repairs of critical metallurgies such as cast iron and other aged brittle materials those are prone to crack due to weld stresses. Ultrasonic peening is widely used in high speed railway fabrication for areas prone to fatigue failure.

Benefits of Peening in Welding

The main benefits to perform peening on welded components are ranging from weld integrity to control of welding defects. Below are the major advantages of the peening in welding:

- Peening introduces compressive residual stresses that improve resistance to fatigue cracking.

- Peening help to reduce to welding residual stresses.

- It provide grain refinement.

- Peening increase the fatigue life of the welded parts.

- Peening by enabling the relaxation of stresses is helpful to control the welding cracks.

Peening is being used in welding of critical parts that are subjected to fatigue such as high speed train bogies, aerospace components and bridges. The effect of peening on weldment reliability is evident by various research results & reports done by major welding research institutes such as TWI & AWS.

Fatigue of Welded Joints

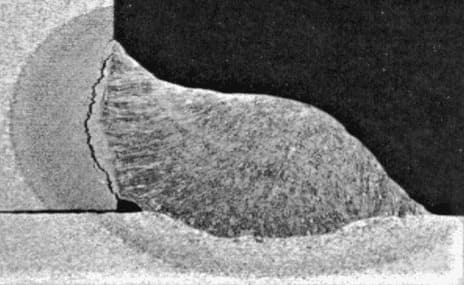

Depending on the nature and orientation with respect to loading of a weld, there are a number of possible sites for the initiation of fatigue cracking. By far the most likely site is the weld toe.

This represents a severe stress concentration, partly because of the abrupt change of section it introduces but also because, in steels, there are sharp inherent defects, in the form of non-metallic intrusions, at the toe,”.

Fatigue cracks readily initiate from such defects with the result that, in contrast to the fatigue behavior of plain material, fatigue crack initiation occupies a negligible part of the fatigue life of a welded joint failing from the weld toe.

Apart from the obvious consequence, that of a low fatigue strength and low fatigue limit, a particularly important one, which is relevant is that the fatigue strengths of welded joints are independent of material tensile strength. Fatigue failure in most of the lower fatigue strength weld details is by fatigue crack propagation from a fillet weld toe. There is little scope for influencing the fatigue strength of such details when the weld is made and therefore if an increase in fatigue strength is required, a post weld improvement technique must be used.