Welding cast iron to steel

Welding cast iron to steel can be challenging due to the differences in their properties and behavior during the welding process.

Cast iron has a higher carbon content than steel, which can make it more brittle and prone to cracking. It also has a higher coefficient of thermal expansion, which means that it expands and contracts more than steel when it is heated and cooled.

To weld cast iron to steel, it is important to use a low-hydrogen welding process, such as Stick Welding aka shielded metal arc welding (SMAW) or MIG welding or flux-cored arc welding (FCAW).

It is also important to use proper preheat and post-weld heat treatment techniques to minimize the stresses on the weld and prevent cracking.

Read more: What is the Best Welding Rod to use for Cast Iron- Find it Here.

Other considerations when welding cast iron to steel include using a nickel base welding rod or filler, using proper joint design, and ensuring that the workpiece is properly cleaned and prepared before welding.

In some cases, it may also be necessary to use special techniques or equipment, such as cold welding or weld peening, to improve the quality of the weld.

Welding cast iron to steel with 7018

Using a low-hydrogen electrode, such as an E7018 (also known as a “7018” electrode), should not be the first approach.

Your first choice should be either Nickel 55 or Nickel 99 welding rod. If these rods not available, then only you should use E7018 rod.

The 7018 electrode is a common choice among welders due to its strong welds and low hydrogen content that produces a tough, crack-resistant weld.

Note: Not all types of CAST IRON can be welded with E7018 Rod. Cast Steel (same as mild steel but in casting form) can be easily welded with E7018 electrode.

To weld cast iron to steel with a 7018 electrode, it is important to follow proper welding techniques and pay attention to the following considerations:

- Preheat the Cast Iron (no preheat requires for steel): Preheating the workpiece can help to reduce the thermal stresses on the weld and prevent cracking. For cast iron, a preheat temperature of 350-450°F (175-230°C) is generally recommended.

- Use a backing strip (if joint permit): A ceramic backing strip can help to support the weld and reduce the amount of heat that is conducted into the cast iron. This can help to prevent cracking and improve the quality of the weld.

- Use proper joint design: When welding cast iron to steel, it is important to use a joint design that allows for expansion and contraction. A single-bevel or “J” groove joint is often used for this purpose.

- Use proper weld technique: It is important to use a consistent, smooth welding technique using short weld runs followed by weld peening.

Welding cast iron to steel with MIG Welding

MIG (metal inert gas) welding, also known as gas metal arc welding (GMAW), can be an effective way to weld cast iron to steel.

To weld cast iron to steel with MIG welding, it is important to use a Nickel base MIG wire and follow proper welding techniques.

Below are the best MIG wires for Cast Iron to Steel Welding.

- USWELDWIRE ENiFe-Cl .035″ Nickel 55 Cast Iron MIG Welding Wire

- Blue Demon ENiFe-Cl (Nickel 55) cast iron welding wire

Considerations when MIG welding cast iron to steel include:

- Use a Nickel base MIG wire: Using a nickel base MIG wire can help to prevent cracking in the cast iron Check out these Nickel base MIG wire.

- Preheat the workpiece: Preheating the workpiece can help to reduce the thermal stresses on the weld and prevent cracking. For cast iron, a preheat temperature of 350-450°F (177-232°C) is generally recommended.

- Use proper welding technique: It is important to use a consistent, smooth welding technique and maintain proper travel speed and wire feed rate to ensure that the weld is of good quality.

- Allow slow cooling After welding, it is important to allow the weld to cool slowly to room temperature to prevent cracking. This can be done by using an insulating blanket.

It is also important to ensure that the workpiece is properly cleaned and prepared before welding, and to use the proper shielding gas to protect the weld from contamination.

Welding cast iron to steel TIG

Here are a few tips for welding cast iron to steel using TIG welding:

- Use only Nickel base welding TIG filler wire.

- Use a low amperage setting (around 50-80 amps) to prevent the cast iron from cracking.

- Use a high frequency start to create a stable arc.

- Use a filler rod that is matched to the base metal, such as Nickel 99 or Nickel 55 for steel or nickel rod for cast iron.

- Preheat the base metals to around 500°F to reduce the risk of cracking.

- Use a backing bar or backing tape to support the weld and prevent warping of the materials.

- After welding, allow the weld to cool slowly to room temperature to prevent cracking.

It is important to note that welding cast iron to steel is not always possible due to the significant differences in the properties of these two materials.

In some cases, it may be necessary to use other methods such as brazing or soldering to join these materials together.

It is always best to consult a welding expert or refer to welding guidelines for specific recommendations on how to best join these materials.

Stick welding cast iron to steel

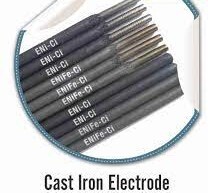

Stick welding of Cast Iron to Steel is carried out successfully using ENiFe-CI (Nickel 55) and ENi-CI (Nickel 99) Welding rods classifications.

Brazing cast iron to steel

Brazing cast iron to steel is carried out using RBCuZn-C and RBCuZn-D Brazing filler rods.

Check out this article for Complete Guide on Cast Iron Brazing.

If you are using solid brazing wires, you need to use the suitable welding flux. However, you can also use flux cored brazing wires.

Welding ductile cast iron to mild steel

Use Nickel 55 or Nickel 99 welding rods for Welding ductile cast iron to mild steel.

Welding high carbon steel to cast iron

Welding high carbon steel to cast iron can be carried out using the Nickel 55 or Nickel 99 welding rods or RBCuZn-C Brazing wire rod.

Cast iron to mild steel welding electrode specification

Cast iron to mild steel welding electrode specification is AWS A5.15.