What is Back Gouging in Welding?

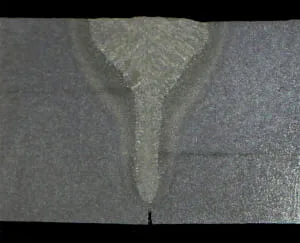

Back gouging is a material removal process that is used to remove weld material that is located on the back side of a weld joint. The objective of Back gouging is to facilitate complete weld fusion from the root side back weld.

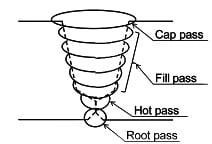

This is a process that is commonly used in Groove welding of Plates & pipe welding, and it helps to ensure that the weld joint is clean and free of any defects. Back Gouging in Welding is followed by welding completely from face side (in small thickness weld joints) or welding root, hot & few Cap pass in higher thickness.

After gouging, the gouged area is checked by Visual Testing & Penetrant Testing to ensure complete removal of any suspected welding defects to ensure a sound weld.

Back Gouging meaning & Definition?

Back Gouging is a technique to remove material to aid repair or modification or to improve weld joint integrity. There are various back gouging methods as explained in this post.

Gouging creates weld grooves, removes defective welds and excess metal from cast steel parts, cuts off weld backing, or cuts through very thick metal parts. The process is a good alternative to planning with carbon electrodes , as there is less noise, pollutants, dust and no ultraviolet radiation.

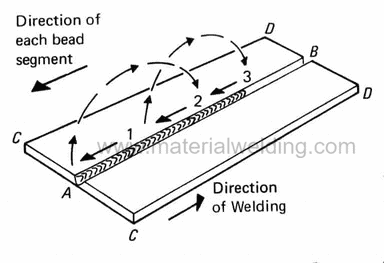

In principle, gouging works like flame cutting. Only another nozzle is required. The user decides for himself which planning depth and speed he wants to achieve. Gouging Techniques: A distinction is made between Step-back gouging and progressive gouging method.

Why Gouging is done in Welding?

Welders use a process called gouging to remove metal from the weld joint. Gouging is done to remove any defects that may be present in the weld joint and to create a smooth surface for welding. Gouging is also used to prepare the weld joint for welding by removing any paint or rust that may be present.

Gouging is done to carry out removal of welding defects, material defects or other imperfections in welds & material to carry out repairs to make the part useable. Gouging is also used to rectify weld fabrications.

Types of Back Gouging Methods in Welding

Back gouging is a material removal process that is used to remove material from the back side of a weld. This is done to remove any welding defects that may have been created during the welding process and to ensure that the weld is smooth and free of any imperfections.

There are several different types of back gouging tools that can be used, each of which has its own advantages and disadvantages.

The main types of Back Gouging Methods in Welding are:

- Grinding

- Arc air gouging (Non-standard term is Gouging)

- Oxy-fuel gouging (Lancing)

- Plasma Gouging

- Chipping

- Laser Gouging

- Chiseling

When is Back Gouging Required?

Welders are often required to remove defects in a weld and then make a repair weld. In order to achieve full penetration (CJP) in the repair weld, the welder may have to back gouge the area around the defect. The main objectives of Back Gouging in Welding are:

- Remove back side of weld root to prepare it for Back Weld.

- Remove materials for welding repair.

Back gouging is the process of using a tool to remove metal from the back side of a weld. This is necessary to create a clean and smooth surface for the repair weld. The welder can use various tools for back gouging as explained earlier.

Back Gouging Procedure

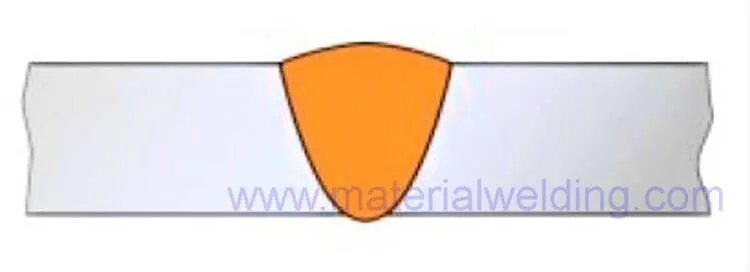

Back gouging is a welding process (material removal) that involves removing weld metal or defective material from the back side of a weld joint or any other area. This is typically done to ensure complete fusion and penetration of the weld on the front side of the joint, as well as to remove any porosity or other defects that may be present for repair purposes.

The back gouging process can be performed using a variety of tools, such as a chipping hammer, a grinding wheel, or a specialized back gouging machine.

The specific procedure for back gouging will depend on the type of material being welded and the equipment being used, but it generally involves using the tool to remove material in a controlled and consistent manner until the desired depth is reached.

Back Gouging Procedure- Step by Step

- Identify the area that needs to be back gouged and use a gouging torch of higher current capacity (600- 1000 amps).

- Set up the welder and ensure that it is properly adjusted and functioning.

- Use the gouging torch to remove material from the back side of the weld joint in a controlled and consistent manner.

- Inspect the area regularly to ensure that the desired depth is being reached and that the material is being removed evenly.

- Clean the back of the joint as you go, to remove slag and other debris that may interfere with the welding process.

- When the desired depth is reached, perform a final inspection to ensure that the joint is free of defects and that it has been prepared properly for welding.

- Proceed to welding the joint. -After welding Inspect the joint and repair if necessary.

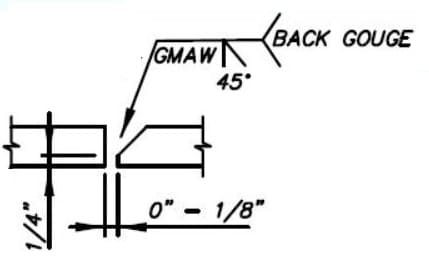

Back Gouging Welding Symbol

Welders use various welding symbols to know about weld type, weld size, weld length & welding process they will use, the direction of welding, and other specific details about their weld.

When we mean a Back Gouging Welding Symbol, actually there are no such welding symbols in AWS A2.4 or ISO 2553. But this is not the end.

The tail section of a Welding Symbol in such cases proves its importance as the details about Back Gouging can be mentioned in the tail section of the welding symbol.

This symbolic information if placed in the tail indicates that the welder will be using a process or technique known as back gouging to remove material from the back side of a weld joint.

What is Back Welding?

Back Welding refers to welding a joint from the “root” side. This is done by depositing the root after the back gouging of the weld. This technique is often used in butt welding of plates & pipes to ensure complete joint penetration (CJP) welds.

Back welding is also used to prevent distortion of the material being welded. Back Welding if carried out properly, ensure the highest level of weld soundness & increase the integrity of the welding joint as well as its service life.

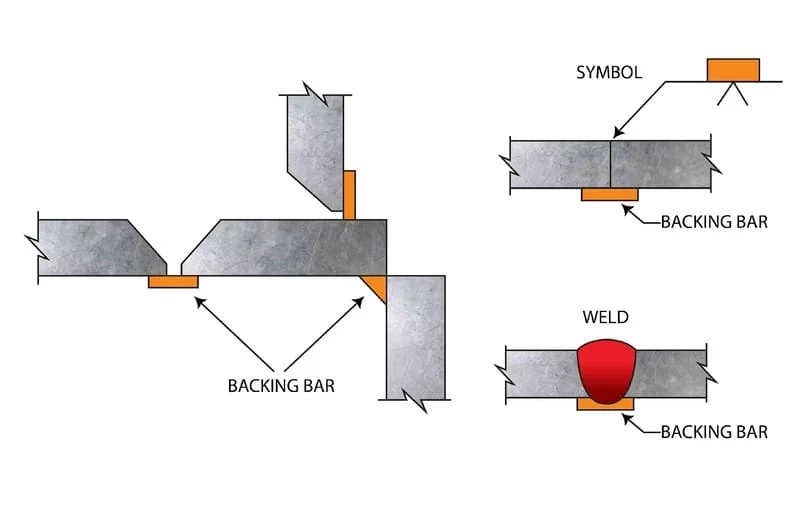

What is the Difference Between Back and Backing weld?

Welders use the terms “backing weld” and “backing material” to describe the bead placement sequence. A Back Weld means the placement of the weld pass after completely welding from one side (usually the face side).

While a Backing Weld is opposite to the back Weld. A Backing Weld is welded at first & then the groove is welded from the face side. A Backing weld is placed on the root side.

Backing & Back Weld symbols are given below.

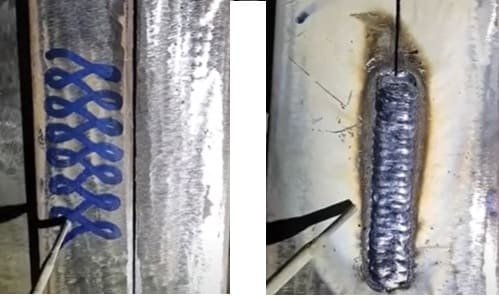

What is Arc-Air Gouging?

Arc-air gouging is a cutting process that uses a combination of heat and an oxygen jet to remove material.

The Arc-air gouging can be carried out using normal Stick Welding (SMAW) Power source (CC Type), although it should be or higher duty cycle as gouging need high amperage & voltage.

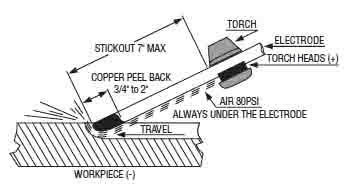

This process uses a specialized tool to remove material from a surface. The tool consists of a Carbon/Graphite electrode (copper coated to reduce erosion of electrode) that is attached to a power supply and compressed air that oxidize & remove the molten metal from weld metal.

When the electrode is energized, it creates an arc of electricity that melts the material on the surface. The molten material is then blown away by the jet of pressurized air attached to the gouging holder. Arc-air gouging can be used to remove metal, plastic, or other materials from a surface.

Arc-Air Gouging is the most widely used Back Gouging method in Welding. This is used to remove roots for back welding, remove defects for weld repairs & remove materials for modifications or other fabrication jobs.

What is Oxy-fuel gouging?

Oxy-fuel Gouging is a process that is often used to remove excess material from a workpiece. This process is achieved by using a high-pressure jet of oxygen to cut through the material combined with an acetylene flame similar to oxy-fuel gas cutting.

The use of oxy-fuel gouging can be an effective way to remove large amounts of material quickly and efficiently.

The heat from the jet melts the metal and causes it to be ejected from the cut. Oxy-fuel gouging is often used to cut steel or other metals that are too hard to be cut with a torch.

What is plasma gouging?

Plasma gouging is a process that uses a plasma torch to remove material from a surface. The torch uses an electric arc to create a plasma stream, which is then directed at the surface.

The plasma arc is formed between an electrode and the workpiece, and the metal is removed by the intense heat and high-speed stream of ionized gas (plasma) that is directed at the workpiece.

This process is used to remove defects, remove excess metal, or shape metal in a specific way. The plasma stream melts the material, which is then blown away by the gas flow.

Plasma gouging can be used to remove material from thin sheets of metal or from thicker pieces of metal. It can also be used to create holes or remove burrs from metal surfaces.

Plasma Gouging Steps

The steps for plasma gouging a workpiece typically include:

- Selecting the appropriate plasma torch and consumables for the material and thickness of the workpiece.

- Setting up the power source and adjusting the settings, such as the amperage and voltage, to match the selected torch and consumables.

- Positioning the workpiece and clamping it in place.

- Setting the plasma arc by striking an arc between the electrode and the workpiece.

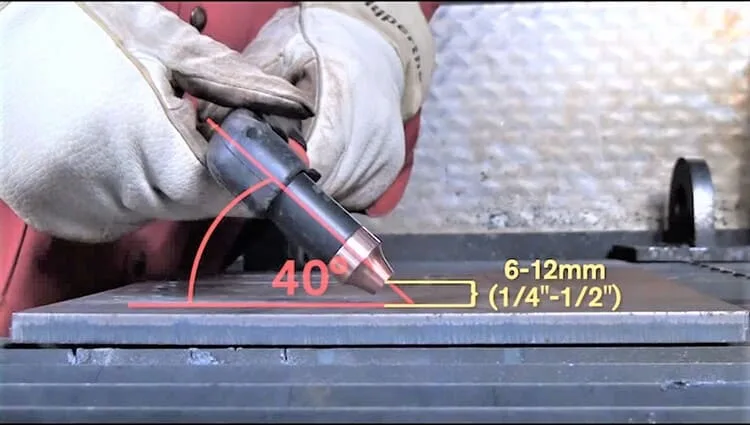

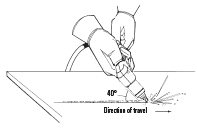

- Holding the torch at a consistent angle (approximately 40-degree) and distance from the workpiece (usually 1/16” or 1.5 mm) to ensure a consistent and controlled removal of metal.

- Moving the torch in a consistent manner along the area to be gouged, while maintaining the proper angle and distance.

- Inspecting the workpiece after gouging to ensure that the desired shape and surface finish have been achieved.

- Cleaning the workpiece and the torch, preparing for the next step.

It’s important to note that safety precautions should be taken before starting to plasma gouge, such as wearing proper personal protective equipment (PPE) and ensuring that the work area is clear of debris.

Plasma Gouging Parameters

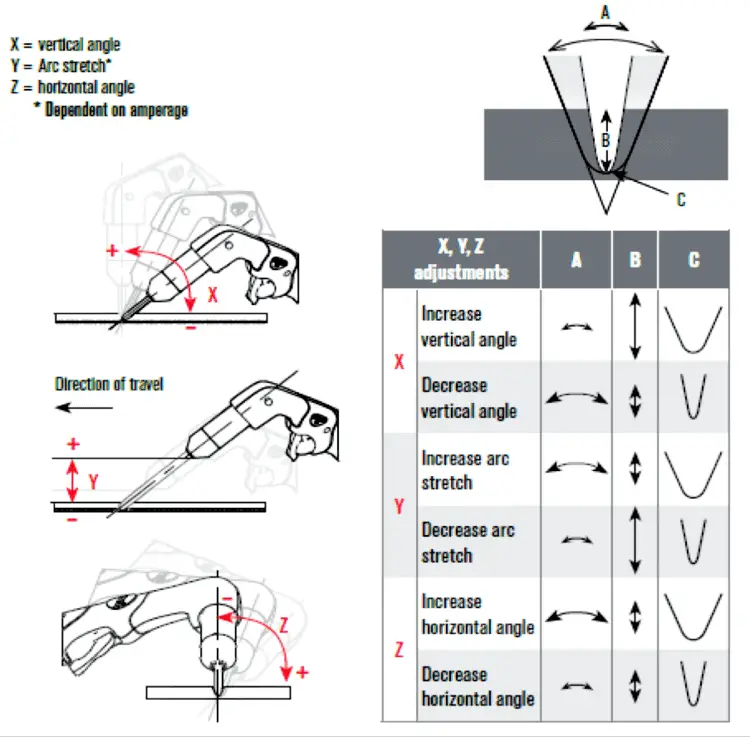

The torch angle is important parameters for Plasma Gouging. Any change in plasma angle, arc stretch, and amperage can affect the quality of plasma gouging.,

The impact of these above parameters on gouging quality is explained in below diagram.

Benefits or Advantages of Back Gouging

The main benefits of advantages of Back Gouging or Weld Gouging are listed below:

- More environmentally friendly than planning with carbon electrodes

- very flexible

- inexpensive

- good error detection

- Welding defects and cracks are clearly visible

- no UV radiation

- Low risk of carbon accumulation

- Economical solution for removing surface material

Similar Posts: