Back Step Welding

Back Step Welding is a welding technique that is very useful to control welding distortion.

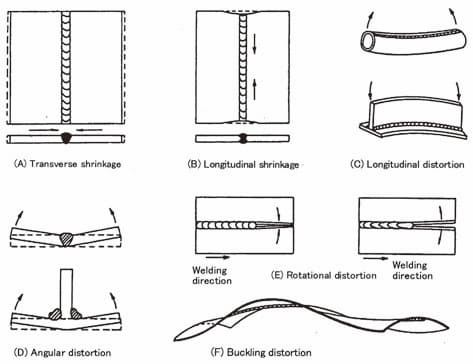

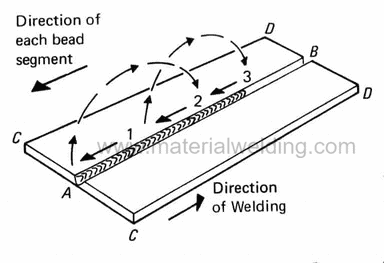

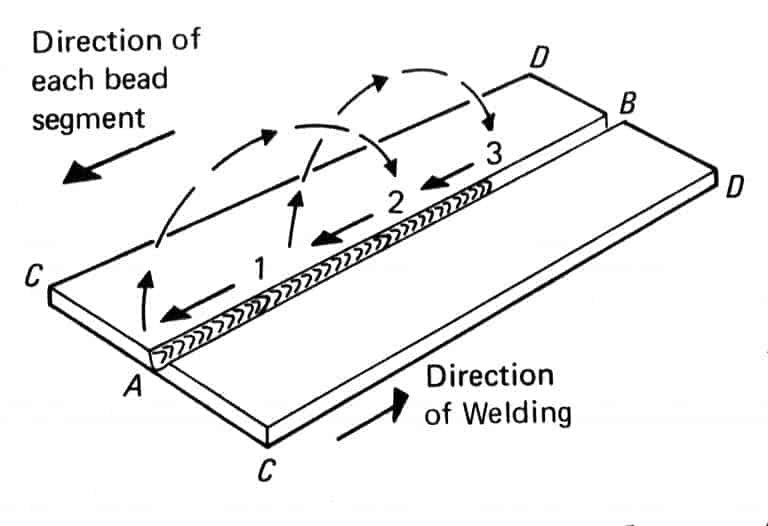

In back step welding, short stitch welds are welded in reverse to the complete welding direction joining each other as shown in the figure below.

Back step welding is not a welding process, but rather a way to weld in reverse to the complete welding direction as a distortion control technique.

This technique can be used on any type of metal and is especially helpful when welding thin sheet metals those are prone to warpage.

Back Step Welding Sequence

In back step welding, the welder travels backward while welding, making a wet pass followed by a dry pass. This sequence is repeated until the weld is complete.

The advantage of this welding technique is that it minimizes the amount of heat input into the workpiece, which lowers the risk of warping and distortion. In addition, this method provides good penetration and a strong weld bead.

Back step welding is commonly used for joining thin & thick materials, such as plate steel. It can also be used on thinner materials if the welder moves slowly and evenly to avoid over-penetration.

This welding technique requires more practice to master than other methods, but it can produce high-quality welds.

Backstep Welding

Backstep welding is a welding technique in which the weld is made in a series of steps, with each step moving slightly backward. This technique can help to control distortion by allowing the heat to dissipate more evenly through the metal.

The first step in backstep welding is to prepare the metal for welding. This includes cleaning the metal and removing any rust or debris.

Next, the welder will set up the equipment and make sure that all safety precautions are in place.

Once the metal is prepared and the equipment is ready, the welder will begin by making a small weld at the start of the joint.

The welder will then move backwards in small increments, making additional welds along the way. The goal is to build up a strong weld without causing too much distortion.

Backstepping Welding

Backstepping Welding is the same as Backstep welding. Welders use Backstepping Welding or back step welding or skip welding with same purpose.

Backstepping Welding is primarily useful for welding sheet metals or smaller thickness where they are easy to get warpage.

Back Step Welding Technique

Back Step Welding Technique is used for welding sheet metals and other materials that are prone to distortion.

IN back step welding technique, following are welding sequence steps:

- Tack welds the plates.

- Start weld from left side of the welding joint.

- Complete first skip weld and start 2nd weld away from the end point of first end.

- Continue the welding in the same pattern. Refer above figure for reference.

What is Back step Welding and why is this technique applied?

Back step welding is a welding technique in which the weld is made by moving the torch in the reverse direction from the welding usual direction.

The purpose of this technique is to help control distortion and to allow for welding distortion prone materials or thickness.

By moving the torch in the reverse direction, the molten metal has a chance to cool slightly before it hits the base metal, which helps to reduce distortion.

Read more:

- https://awo.aws.org/glossary/backstep-method/

- Skip Welding & Back Stepping Techniques

- What is Welding Bead and their Different Types with Uses?

- https://www.researchgate.net/figure/a-Back-step-welding-b-Skip-welding_fig3_327700909