What is Distortion in Welding?

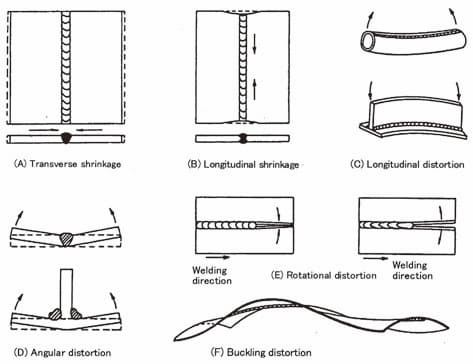

Distortion is the general term for the component’s differences from the intended shape after heat input and cooling to room temperature.

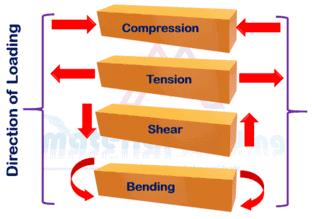

Distortion is being initiated by plastic deformations due to local and timely differencing heat expansion and shrinkage. Shrinkage is seen as the contraction of the, for example, heated area of a component by welding during cooling.

For prevention or reduction of distortions and residual stresses a distinction is made between preventive applied measures (during engineering and partly during manufacturing) and subsequently applied measures.

For economic manufacturing, it is always beneficial to already consider the initiation of distortions and residual stresses at the engineering phase. However, the quality of manufacturing is important.

The quality of welds depends, among others, on:

1. the base metal

2. plate thickness

3. the welding process

4. the welding fixtures and

5. the craftsmanship of the welder.

From this respective, continuous cooperation between engineering and manufacturing should exist.

Control of Distortion in Aluminum Welding

The distortion in aluminum welding or copper alloys can be prevented by using proper welding sequence, welding direction, pre-setting, controlled heat input, etc. Detailed process of distortion control in aluminum involves:

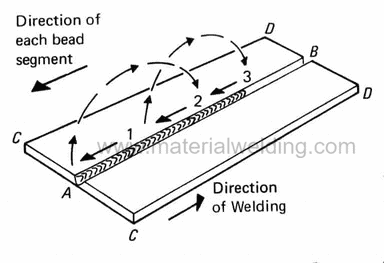

1. Sequence

Welding sequence is the primary action that needs to control to reduce or eliminate the distortion in welding.

A welding sequence for fabrication, built-up, or welding of additional members shall be planned by balancing the welding stresses. Example- such as using double V groove instead of single V for the thickness more than 0.5 inches for aluminum.

2. Direction of Welding.

Start welding by controlling restraint. Before starting full welding, placing tack welds of sufficient length to avoid distortion.

3. Crack Prevention.

Welds having prone to high severe stresses during welding shall be properly preheated, tack welded, and clamped to ensure that there is sufficient weld strength for joints to prevent the cracking to take place.

Clamping if placed shall be removed once the part cools to room temperature.

4. Corrections.

Welding is a thermal-inducing process prone to have distortion and it is not always possible to control it fully.

Members distorted by welding usually require straightening at ambient temperature by mechanical means or using balanced heat supplied by a heating torch. For straightening by heating the torch, it must be followed by an experienced person and using a straightening procedure.

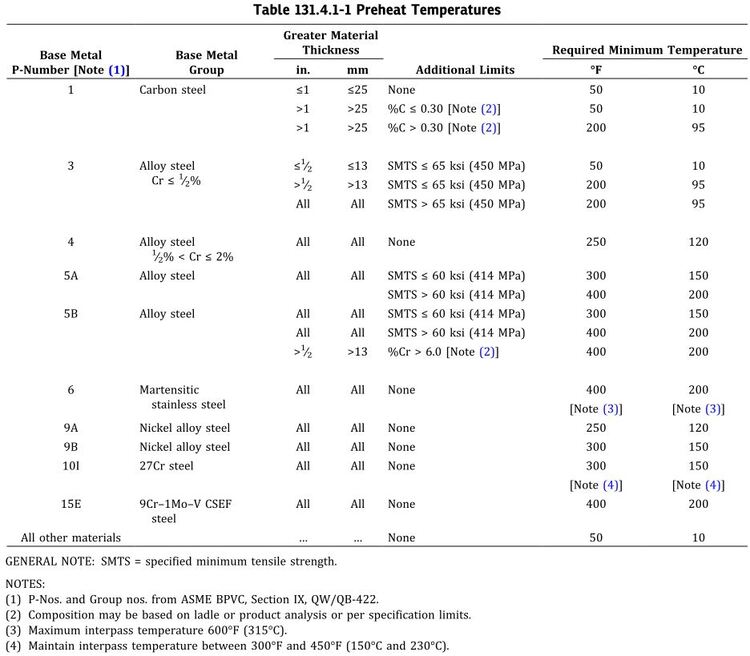

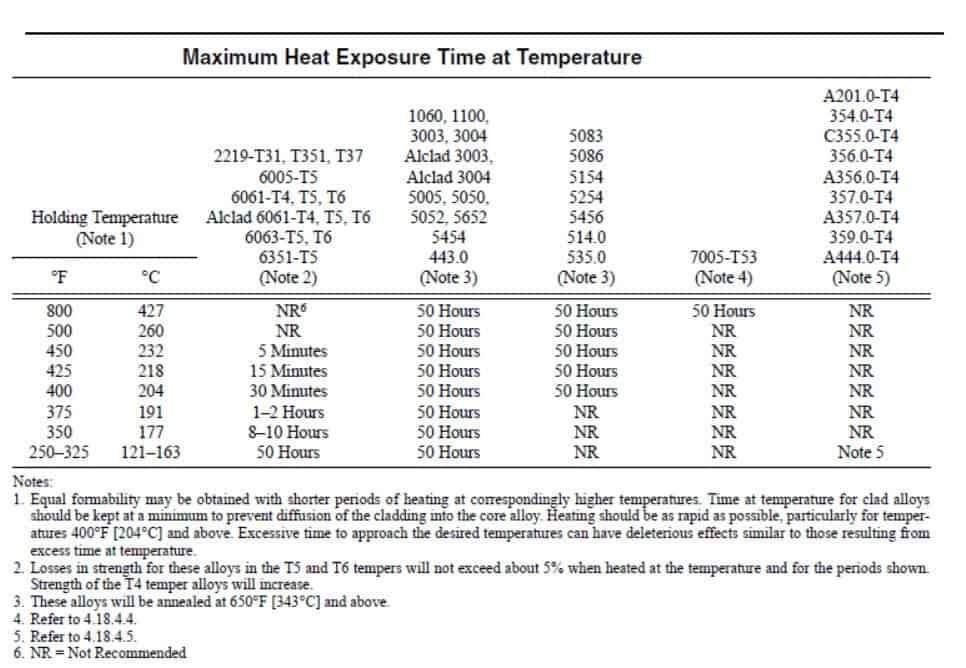

Maximum holding times for the forming and straightening of aluminum alloys at various temperatures are given in the below table.

5. Heat input

The heat input can be controlled/minimized by the choice of an appropriate welding process. The weld settings also are of influence.

For example, during manual metal arc welding, the choice of electrode type, the electrode diameter, and the welding current are to be considered.

Along with the choice of welding process also the preheating as heat-input should be considered. It is specifically being applied, among others, to reduce the extent and the enlargement of the residual stresses and therefore to reduce the distortion. I.e. Preheating is beneficial according to the following reasons:

- Reducing stress peaks in thick-walled components.

- improvement of the fusion of base materials with high thermal heat conductivity ( aluminum, copper) .

- reducing the heat input and the HAZ.

- welding under low temperature / cold weather conditions.

- Reducing the residual stresses of base materials with limited ductility (for example steel casting)

It is recommended to apply a uniform heating on both sides of the weld joint. The required preheating is to be determined in dependency of the chemical analysis, the heat input, the heat conductivity, material thickness and the type of joint.

Also the design of the weld joints and the welding sequences are important for the heat input. For example, in case of thin sheet metal constructions with long welds it useful to apply intermittent welding in order to prevent unnecessary distortion.

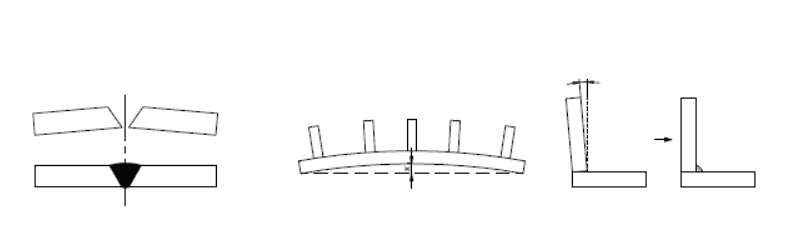

6. Pre-setting /pre-bending

One possibility in order to guarantee a free distortion after welding is for example applying a pre-setting or pre-bending of the component in the opposite direction of the angle shrinkage /distortion to be expected.

This can be applied to as well as V butt welds as for fillet welds. Pre-setting of sheet metals in the opposite direction of the expected angle deformation of butt welds.

6. Clamping / pre-clamping

The earlier mentioned measures of pre-setting or pre-bending counteract the expected distortion. Due to the free shrinkage high stresses are not being generated. Another possibility for preventing angle distortion is by means of clamping or pre-clamping.

In doing so the components are placed into a fixture in a way that they can move in the direction of the plane (free transverse shrinking of the weld!) but lifting out of this plane (angle distortion) is being prevented by holding-down clamps.

Such fixtures however have to be deformation rigid and be able to take huge forces.

This can either be achieved by clamping ) a component or by mounting several components to each other e.g. back-to-back assembly.