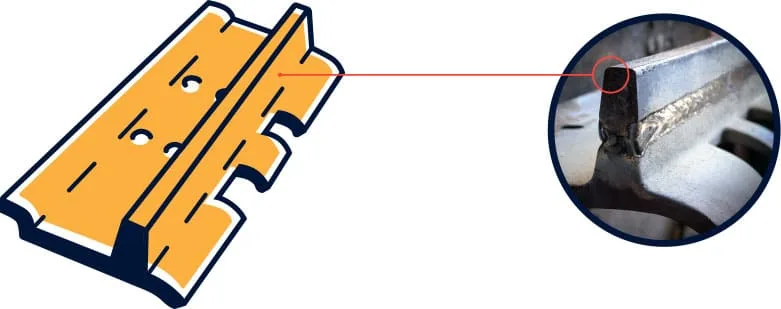

What is Tack Weld?

Tack Weld are either a permanent weld or temporary weld, welded to hold the pieces of a weldment or component assembly in right alignment until the final welds are completed. When a tack weld is temporary, they are removed by grinding before making the actual welding.

Permanent tack welds become the part of the weld as they are fused during the welding run. Such Tack welds those are incorporated in the weld need to be of the acceptable quality level as applicable for the actual weld. As stated in AWS D1.1, When RT is used, no tack welds shall be in test area of the WQT coupon.

Often tack welds are used in stainless steel welds joints to limit the shrinkage. Tack welds are also used to hold parts during welding to prevent weld cracking due to weld stresses.

Tack welds that supposed to be the part of the welding or merged with welding must be made using the same welding electrode that is used for welding of joint.

Such types of tack welds requires full cleaning of weld joint before welding as the tacks are going to be the part of the weld. Tack welds placed via multipass should have cascaded ends so that they can be easily merged with the welding with minimal efforts.

Who is a Tack welder?

AWS D1.1-Structrual Welding Code defines tack welder as:

‘‘A Tack welder is the person who perform small length welds (tack welds) to hold the parts during fitment stage in right alignment. Final welding is carried out by the welder over the these tack welds or by removing them.”

Tack welder qualification is mandatory in fabrication to ensure the tack welder’s skills to deposit sound tack welds.

The WQT for tack weld qualification shall not be considered as a reference during actual fabrication. The actual tack welding on the job will be made in accordance with a qualified WPS only.

Preheating for Tack Welds

Tack weld require same preheat as required for the base metal. The rational is that tack weld also produces same heat input as induced by the full weld.

Materials such as Cr-Mo, HSLA or high carbon steel for example, if not preheated before tack weld can result in the welding cracking in the tack welds. As well as they will produce very high hardness HAZ and weld metal.

Click here to know What shall be the minimum & maximum length of tack welds

Qualification of tack welder according to ASME Section IX

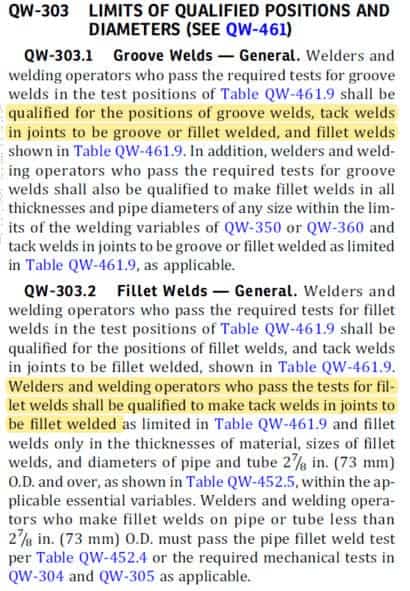

ASME Section IX does not call separate qualification for Tack Welder. As per ASME Section IX, clause QW-303.1 Groove Welds, welders who are qualified for groove welds are also qualified to make tack welds in groove and fillets within the range qualified.

Similarly, welder who are qualified for Fillet weld are only qualified to make tack welds in fillet welt joints.

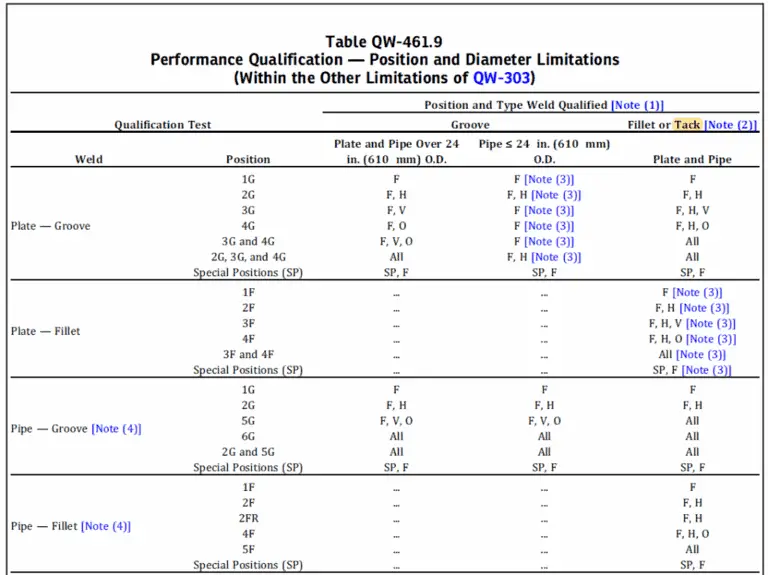

As per the ASME Section IX, table QW 461.9 welder who qualify groove weld on plate can weld tack welds in groove, fillet on plates and pipes.

Qualification of tack welder according to AWS D1.1

AWS D1.1 require separate qualification for tack welder and does not accept qualification based on groove weld or fillet weld qualified welder.

As per the AWS D1.1, clause 6.16.1.2 for Tack Welders, Each tack welder is required to be qualified using a plate WQT for each welding position that simulates the actual welding requirements.

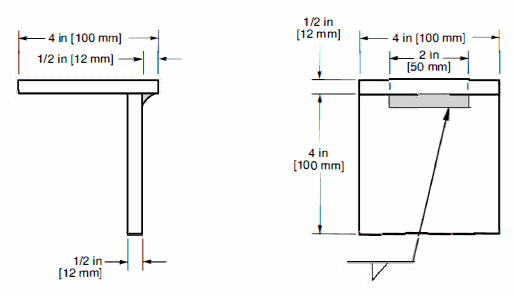

As per AWS D1.1, clause 6.16.2.2, For WQT, a tack welder has to weld a Fillet tack weld of 0.25 inches or 6 millimeters maximum size with a length of roughly 2 inches long. This tack sample shall be tested for the Fillet Weld Break test to check the welding quality.

Tack welder will be qualified once he or she passes the fillet break test. He/ She is qualified to perform tack welding of all types of welding joints excluding the complete penetration butt welds, weld welded single side without backing.

Examples of such joints are Groove welds, and TKY joints.

Tack welder is qualified to weld the above joints for the welding process & welding position, he/ she is qualified.

These tack welds of the above-excluded joints shall only be carried out by a fully qualified welder/ welding operator for the required joint & welding position.

Range of Qualification for Tack Welder as per AWS D1.1

Tack welder qualification test is accessed by Fillet Weld Break Test. The welder who passes this test is qualified to perform tack welding of all welding joint types excluding the complete penetration butt welds, weld welded single side without backing.

Examples of such joints are Groove welds and TKY joints. This qualification is valid for the welding process used during the test.

Tack weld of above-excluded joints shall only be welded by a fully qualified welder/ welding operator for the required joint & welding position.

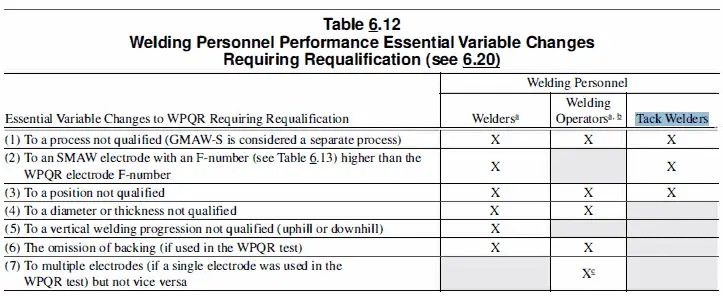

The essential variables for tack welder performance qualification according to AWS D1.1 are given in Table 6.12 as shown in the below figure.