What does 6GR mean in Welding?

6GR is a special welding position used for welder testing & production welding. 6GR full meaning Stands for:

- The number ‘6’ here stands for the Welding positions.

- The letter G stands for Groove.

- The letter R means restriction.

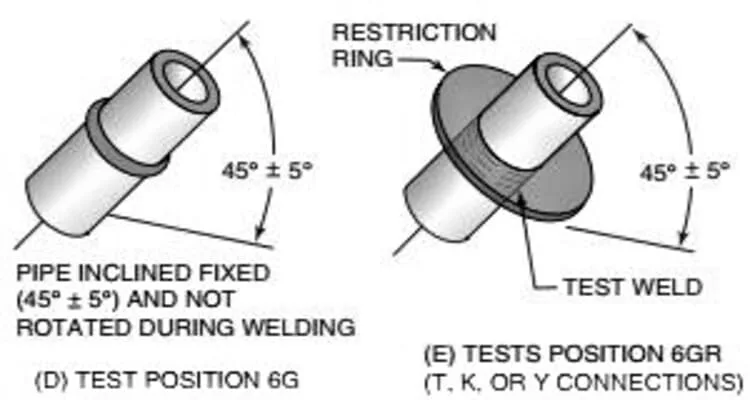

6GR Welder test Position is specified in AWS D1.1 Code. While in ASME Section IX, there is only 6G Welding position for performance qualification. in the ‘6GR’ term, ‘R’ means the Restriction Ring.

6GR Welding Position

In the 6GR Welding Position, a welder demonstrates a very high level of welder skills required for Welding on critical structures.

The main difference between a 6G Welding position & 6GR welding position is the:

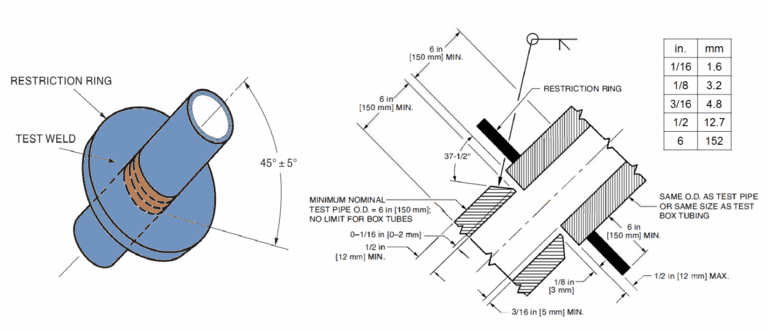

- 6GR Position uses a restriction ring above the groove as shown in the below figure. This restriction ring is tack welded to the upper side pipe.

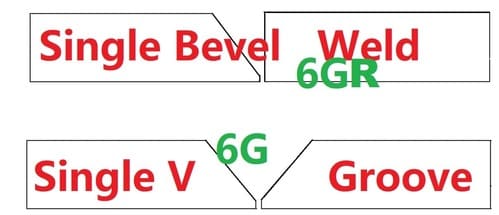

- 6GR welding test coupon uses a Single bevel joint (one pipe without any bevel preparation) while the 6G test coupon uses a Single V joint. Refer to the below sketch for joint details.

- 6GR Qualification Test Coupon pipes are having dissimilar thicknesses (usually a thickness difference of 3/16 inches). Pipe with higher thickness has no weld preparation. While in a 6G test coupon, both pipes have the same wall thickness.

The Lock ring or also Restriction Ring is placed at a maximum of 1/2 inches from the weld circumferential center line as shown in the below sketch.

“The lock ring restricts & simulates the actual restrictions observed during the welding of T, K & Y tubular connections.”

So, what are T, K & Y joints?

Here, -Т, -К, and -Y letters refer to the type of joint shape in tubular connections. These types of joints are used to simulate the difficult welding conditions used during welding or -T, -K & -Y type tubular connections in structural welding mainly as per AWS D1.1 code.

As stated in AWS D1.1, Table 10.8 & Clause C-10.18: A Welder who is qualified using a 6GR Test coupon is also qualified to weld T-K-Y Welding connections & butt welds in Box Sections of similar configurations.

6GR Welding Position due to the restrictions placed during WQT and one face without any weld preparation is quite tough to pass the welder test, mainly the root pass. So, before you weld a 6GR test coupon, practice for the 6G position in advance. Then it will be easy as you know the position restrictions and welding techniques.

Difference Between 6G and 6GR Weld Test Position

If you notice, you will find the difference between 6G & 6GR is the ‘R’ in the 6GR. The letter ‘R’ specifies that 6GR welding consists of a restricting ring where ‘R’ literally means Restriction.

Another main difference between welding positions 6G & 6GR is the Weld Bevel Preparation. In a 6G test coupon, both the pipe pieces have bevels.

The weld joint preparation is a Single V. But in the 6GR test coupon, one pipe is without bevel while the other is bevel preparation. The type of groove is a Single Bevel groove in 6 GR.

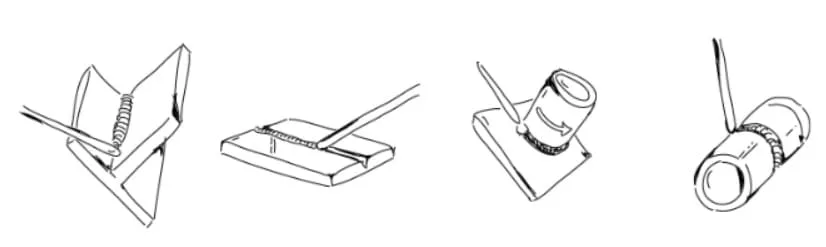

Additionally, in the 6G certification test, the welder has to weld in all positions while the 6GR position is for TKY joints. Both 6G position & 6GR welding position are meant for welder performance qualification. 6GR is as per AWS D1.1 while 6G is followed in ASME as well as AWS.

6GR qualified welders are not readily available as they require extensive welding skills to produce a sound weld. A very high level of welder skill (as demonstrated by the 6GR test) is required for the 6G weld test. So 6G test tends to be the most difficult test in a welder test certification.

6GR- Important Welding Test Position

6GR welding test position is the toughest Welding position for Stick (SMAW) Welder. Compared to the 6G welder test, 6GR brings more restrictions on the movement of the rod and viewing the weld puddle during welding.

6GR welding position is widely used for welder qualification for offshore platform structures welding is carried out by these qualified welders as per AWS D1.1 code. 6GR Welding position qualifies a welder to weld -T, -K & -Y joints.

AWS 6GR Welder Test

in AWS D1.1, 6GR Welder Test Requirements are specified. According to the AWS D1.1, Table 10.8- a welder who performs test coupon (WQT) welding in the 6GR position, is qualified to weld in all positions including plates & Box tubes. This includes Groove with CJP, PJP, all fillets in Plate groove, and pipe. Box tube butt, T-K-Y and Fillet Welds.

Test Requirements for 6GR Welder Test Qualification

According to the AWS D1.1, Table 10.13, the following are the test required for 6GR Welder Qualification:

- In case of Pipe/ Tubing CJP Groove WQT: 2 Face Bend & 2 root Bend or 4 Side bend (side bend when thickness>3/8 inches). Bend Test can be substituted by Radiographic Testing (RT) as permitted in Table 10.13, footnote-d.

- In case of T-K-Y CJP Groove Weld WQT: 4 Side Bends only in case of Pipe, 4 Side Bend & 4 macros in case of Box Groove. Bend Test can be substituted by Radiographic Testing (RT) as permitted in Table 10.13, footnote-d.

Location for Bend Test specimens for Welder Performance Qualification is given in the AWS D1.1, Figure 10.23.

Coded welder meaning

A coded welder is a professional who has been trained and certified to weld metal structures together. The code refers to the American Welding Society (AWS) welding code such as AWS D1.1 or ASME Section IX, which sets the standards for welding in the United States.

Related Reading: Who is a Coded welder?

To become a coded welder, one must first complete an accredited welding program and pass a welding test. The AWS welding code is used to determine if a welder meets the minimum requirements for welding quality & safety.

Coded welders are in high demand due to the increasing popularity of metal fabrication. They are responsible for ensuring that metal structures are properly welded together, which is essential for both the strength and stability of the finished product.

6GR Welder Qualification Limitation

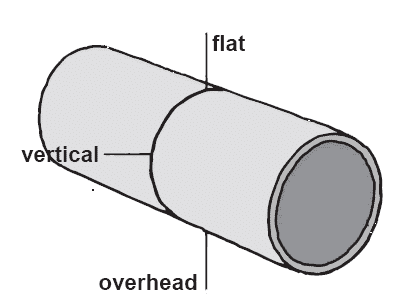

In general, a 6GR welder qualification refers to a welding qualification test conducted on a pipe joint in the 6G position. The 6G position is a fixed position where the pipe is inclined at a 45-degree angle, and the welder must rotate around the pipe while welding.

The qualification test for a 6GR welder typically involves welding on a pipe joint with a specific joint configuration, welding process, and welding procedure specified by the applicable welding code or standard. The test is designed to evaluate the welder’s ability to produce sound and quality welds in a challenging position.

The specific limitations and qualifications for 6GR welders may vary depending on the welding code or standard being followed, as well as the specific requirements of the project or industry. It is essential to consult the relevant welding code or standard, such as AWS D1.1, for specific details regarding the limitations and qualifications for 6GR welders.

Similar Posts

- Welding positions for plate & pipe and their qualification range

- How to be a Certified Welder?

- Welder qualification test WQT acceptance criteria as per AWS D1.1

- What is the Welder qualification test WQT acceptance criteria for ASME Section IX

- What shall be the minimum & maximum length of tack welds & qualification requirements for Tack Welder?

- Groove weld definition, types, symbol

- Welding Symbols

6GR welding position means- G means Groove and R means restricted.

Very informative article.