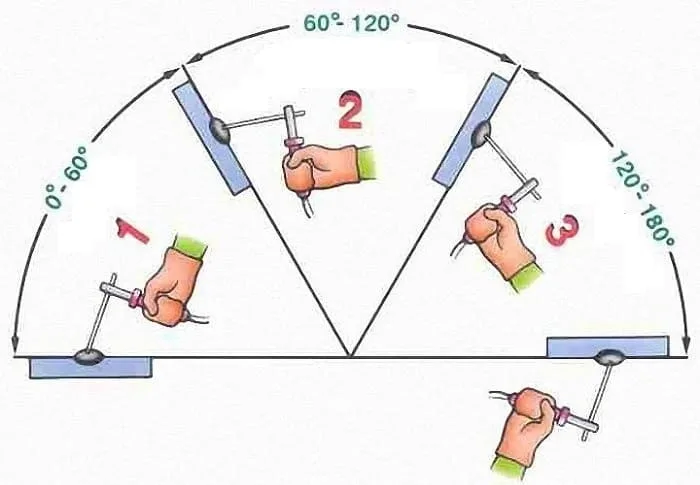

The Welding Positions are standardized in DIN EN ISO 6947 according to position of welds during welding.

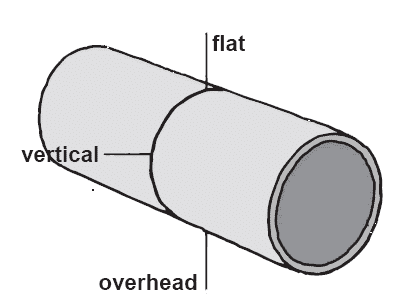

The position of the weld seam during the welding process is generally referred to as the welding position. This results from the position of the workpiece to be welded and the accessibility of the torch or the electrode to the weld seam.

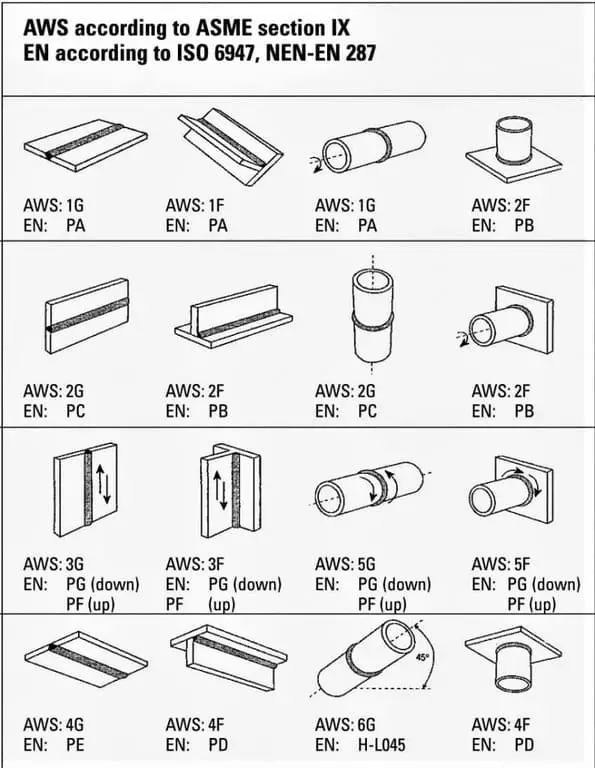

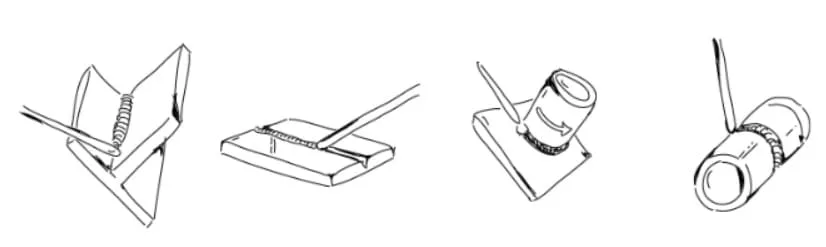

A distinction is made between different welding positions for butt welds and fillet welds. The following overview shows the different welding positions and their application.

The Flat position (PA) is considered to be the ideal position. In this position, the molten pool flows due to gravity towards the downside. All other positions are described as out-of-position welds because they are not ideal positions for the welder to work.

ISO 6947 Welding Position Chart

Read more: ASME Welding Positions.

Welding Positions according to the ISO 6947

The individual welding positions as per ISO 6947 standards are the:

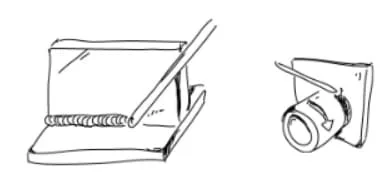

PA Welding Position

PA – The ideal welding position or down position (For Horizontal welding of butt or fillet welds in a flat position).

PB Welding Position

PB welding position is the normal welding position used for Horizontal fillet welding.

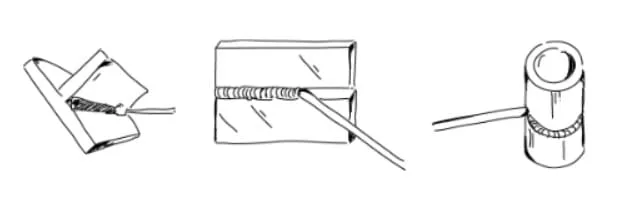

PC Welding Position

PC welding is a transverse position or transverse welding ( Welding is carried out in a horizontal direction on a vertical wall).

PD Welding Position

PD welding position is a Horizontal overhead position used for fillet welding on plates or plate to pipe welding.

Welding is deposited from the bottom side of the weld as shown in the below figure.

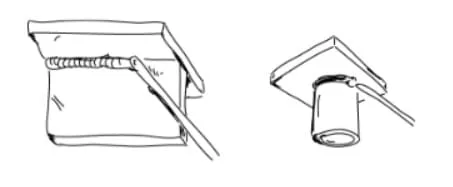

PE Welding Position

PE Welding Position is an overhead position for making groove welds in plates. In the PE weld position, the weld is deposited from the bottom side of the weld similar to the PD welding position.

PF Welding Position

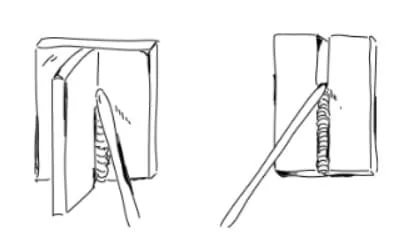

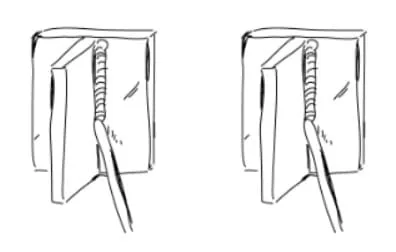

PF welding position is a Vertical uphill progression welding position. This is a Rising position to carry out the vertical welding from the bottom to the top of the weld joint.

PG Welding Position

PG Welding Position is a Vertical downhill progression welding position. In the PG welding position, welding is deposited vertical downhill from top to bottom of the welding joint.

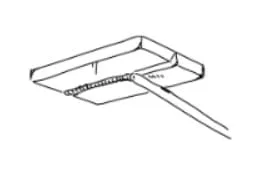

PH Welding Position

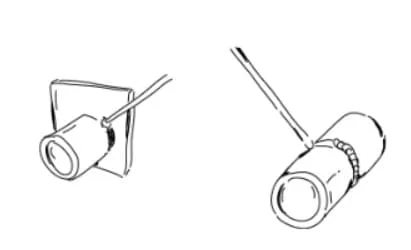

PH welding position is for pipe-to-pipe groove welds and pipe-to-plate fillet welds. In the PH welding position, welding is carried out in a vertical direction from the bottom to the top of the welding joint.

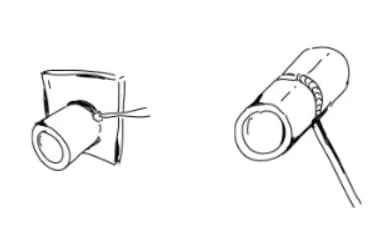

PJ Welding Position

In the PJ Welding position, welding is carried out from the top to the bottom direction (opposite to the PH welding position).

PJ welding position is for groove welds in pipes and pipe-to-plate fillet welds.

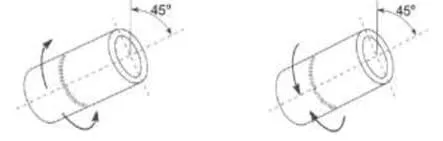

H-L045 and JL045 Welding Positions

H-L045 and JL045 Welding Positions are for inclined pipe welding. 45 means the inclination angle in this position.

In HL045 welding pipe is fixed and welding is carried out in an uphill direction (bottom to top side).

In JL045 welding pipe is fixed and welding is carried out in a downhill direction (top to bottom side).

PK Welding Position

PK Welding Position is applicable for Pipe welding, This position is for orbital welding of pipes.

Read more: ASME Pipe Welding Positions.