What is Overhead 4G Welding?

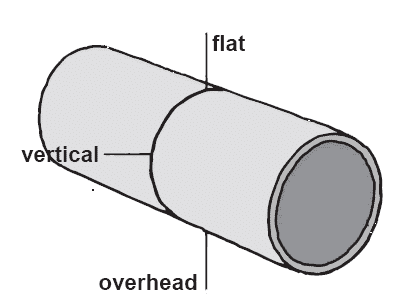

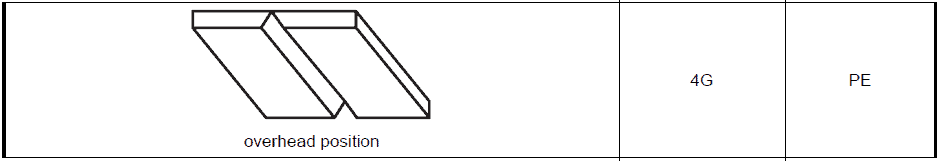

Overhead welding is also called 4G position as per ASME and PE position as per ISO 6947 when welding groove welds. For fillet weld welding position is called 4F. In the overhead position, the welder performs the welding from the bottom side of the job as shown in the below picture.

Overhead welding requires a very skillful welder to manipulate the welding electrode and control the weld puddle which keeps falling down due to gravity.

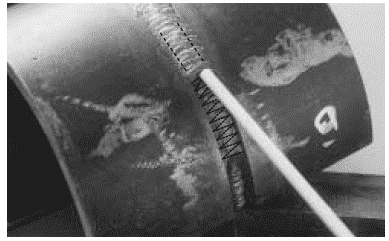

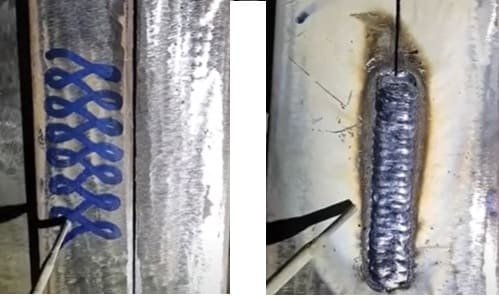

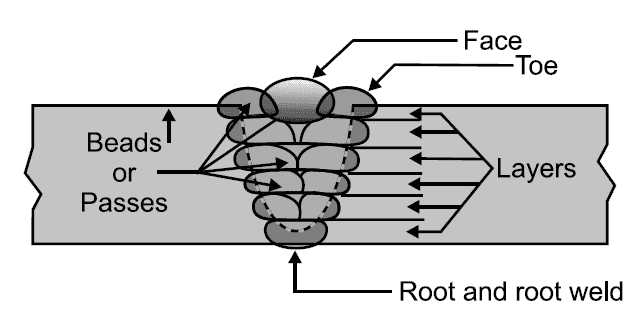

The welder’s skill to weld uniform stringer beads is highly important when welding overhead welds as weaving techniques that will produce a lot of heat and weld metal are not suitable for overhead welds.

Tips for Stick Welding in 4G Overhead position

Flat, horizontal, vertical, and overhead are the welding positions classified as per ASME Section IX and ISO 6947. Out of these 4 positions, the flat is the easiest one and overhead is the most difficult position for welders.

There are a lot of challenges for welders when welding in overhead positions such as:

- Weld deposit against gravity.

- Falling spatters

- Controlling the weld puddle

- Controlling the welding speed

Welding groove welds in the 4G overhead position

Electrode: E6010 for root pass, diameter 3/32 inch or 2.5 mm.

E7018 or E6013 for fill passes, Diameter 3.15 mm or 1/8 inch for overhead welding.

Welding current: It is always the best option for the welder to choose the welding parameters that suit him best. As stick welding is a manual skill and each person adapts to different welding parameters and setup. Ideally, you should start with the lower range and then slowly set up a higher current.

Starting the weld: First of all, With the electrode, pointed slightly into the joint, strike the arc in the joint & maintain a constant arc length. During welding make sure to:

■ Keep a very short arc length to have a good fusion and bead appearance. Higher arc length will decrease the welding current and can result in more spatters and a lack of fusion.

■ When starting the weld, follow the step-back technique and move the welding rod slowly once the weld puddle is sufficient in size and heat.

Once there is sufficient molten metal in the weld puddle, the weld profile will starting become convex due to the high amount of weld metal in the pool.

So, it is important to have a uniform welding speed having a bit faster to keep the weld bead flat instead of convex. If you will keep the welding arc in the molten pool it will result in the metal face having metal hanging from the weld like icicles.

During welding, follow these tips for good welding results (all these during welding, a quick decision at the same time):

■ Once the molten weld puddle cools, move the welding arc to the weld center.

■ Follow a uniform welding sequence to have an even weld profile.

■ Hot-cold-hot-cold.. notice the weld areas accordingly and follow the welding arc.

■ Once the weld is cool, clean it and inspect for any welding flaws.

■ Practice is the key.

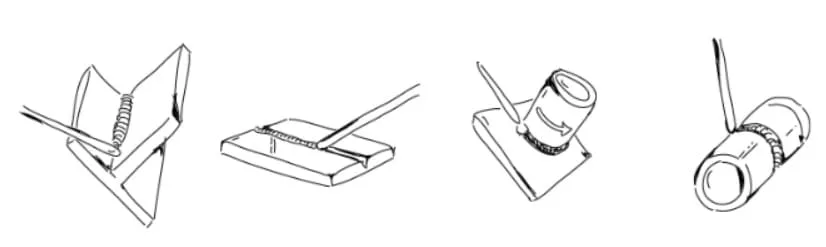

Welding Fillet welds or Lap joint in 4G Overhead position

Welding of fillet weld or lap joint is similar to like welding fill pass in an overhead groove weld and can be easier than welding groove weld joints in this position.

When welding fillet weld in overhead with stick welding, the welder needs to master the skills of stringer bead with a combination of little weaving.

Weaving techniques in general are not beneficial in overhead welding as they will produce heavy molten metal and it’s difficult to hold in the overhead position due to gravity.

When welding fillet weld or lap joint in the overhead position, set up the parameters as stated above.

Start the arc with an electrode pointed slightly into the weld joint and strike the arc. A constant welding arc needs to be maintained to ensure control of the weld puddle.

- Deposit the weld pass using stringer beads.

- Use low welding current to avoid undercut during welding.

- Overhead welding requires a fast travel speed for good weld quality.

- Control weld interpass i.e. let weld cool a bit before you deposit the next pass or weld layer.

- Repeat the welds as required until the weld is finished.

Tips and techniques for MIG welding in the 4G overhead position

in MIG welding the molten weld pool should be kept as small as possible for easier control. This can be achieved by using lower welding current settings, by using a longer wire stickout which will result in low current, fast travel speed, or by pushing the molten weld pool to let it cool fast. The technique used is the welder’s choice for best results.

Choose the right diameter of the wire

Welding MIG in the overhead position should be carried out using small diameter wires e.g. 0.8 millimeters (0.030 inches) or 1.0 millimeters (0.035 inches).

For overlead welding it is good to use small wire diameters as they produce a small weld pool and run on a lower welding current.

0.045-inches diameter MIG wire can also be used but welding ampere shall be kept to low and short circuit mode to be chosen.

Choose the right metal transfer mode

A short circuit transfer mode must be selected when welding in the overhead position. Spray transfer or globular transfer is not going to work in the overhead position.

The pulsed metal transfer mode can also be used if a pulsed welder (power source) is available.

Short circuit mode produces small metal droplets by short circuit transfer and gives better control on weld puddle.

Similarly, a pulsed transfer mode works with low heat input, and controlled total heat into the weld puddle allows minimal spatters in an overhead welding position.

Click here to learn Metal Transfer Mode in GMAW, FCAW & SMAW

Short circuit mode gives a small molten weld pool size—The smaller size of the molten weld pool allows surface tension to hold it in place. Also, as smaller weld pools require low current, it produces fewer undercut issues.

Check your wire feed rate

The wire speed shall not be kept very high and also it must now be too low. Most of the welders, keep wire-speed very low thinking they need very less wire, and end up with bad-looking welds. So, maintain a proper wire feed rate for out-of-position welding.

Root run and fill pass importance

Each pass in overhead welding is differently controlled. A root pass in the groove weld is open and needs very low heat input and a small wire deposit.

So root run welding must be welded with low ampere and stringer beads. Fill passes require higher power than root run and can be combined with little weaving to allow more weld deposit.

Count your wire stickout

The wire stickout must be kept too short. Making a higher stickout will give rise to voltage and create a mess in the welding. The most important part of MIG welding for overhead welds is to keep your stickout short.

Click to know What is Welding Electrode Stickout for GMAW & TIG?

Maintain short arc length

Another important thing that requires to be short is the arc length along with the stickout in MIG welding. A short arc length helps to control the welding voltage and allows little fluctuation in the current.

So, the shorter your arc length in MIG welding, the better looking and cleaner your weld beads.

Faster Travel speed

Higher travel speed helps to cool the weld metal, avoid bigger size weld puddles and increase welding productivity in an overhead welding position.

One of the main issues is the lack of weld penetration at weld start due to fast heat dissipation can be solved by using the step-back technique for weld start or keeping a slow travel speed initially.

During welding, following a high travel speed minimize the welding distortion and help to keep the weld cool which is essential for welding in an overhead welding position.

Keep your extra protection ON

When welding overhead, extra personal protection is required to reduce the danger of burns. It is good to wear Leather sleeves and leather jackets and caps to avoid any skin burn due to splashed hot metal.

Always wear a fully maintained coverall and especially protect your skins from hot molten spatters and NEVEL lose your helmet. Any spatter falling in the eyes can be the pain of life.